Automatic assembling and detecting equipment and process method for mobile phone card seat

A technology of automatic assembly and mobile phone card holder, applied in the direction of assembly machines, metal processing equipment, measuring devices, etc., can solve the problems of low product qualification rate, low production efficiency, high product cost, etc., achieve compact structure, reduce labor costs, The effect of high market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

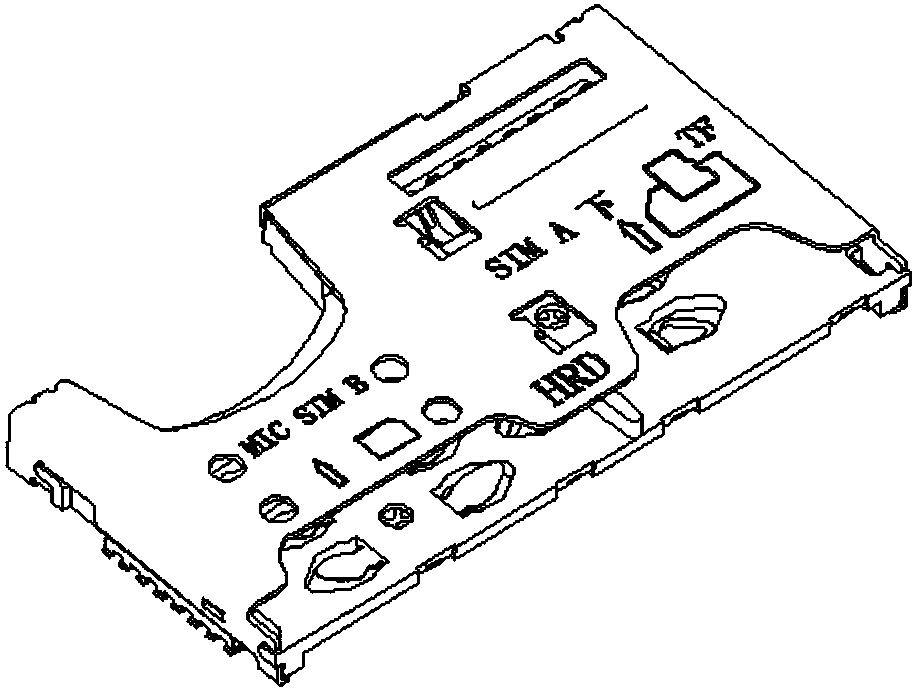

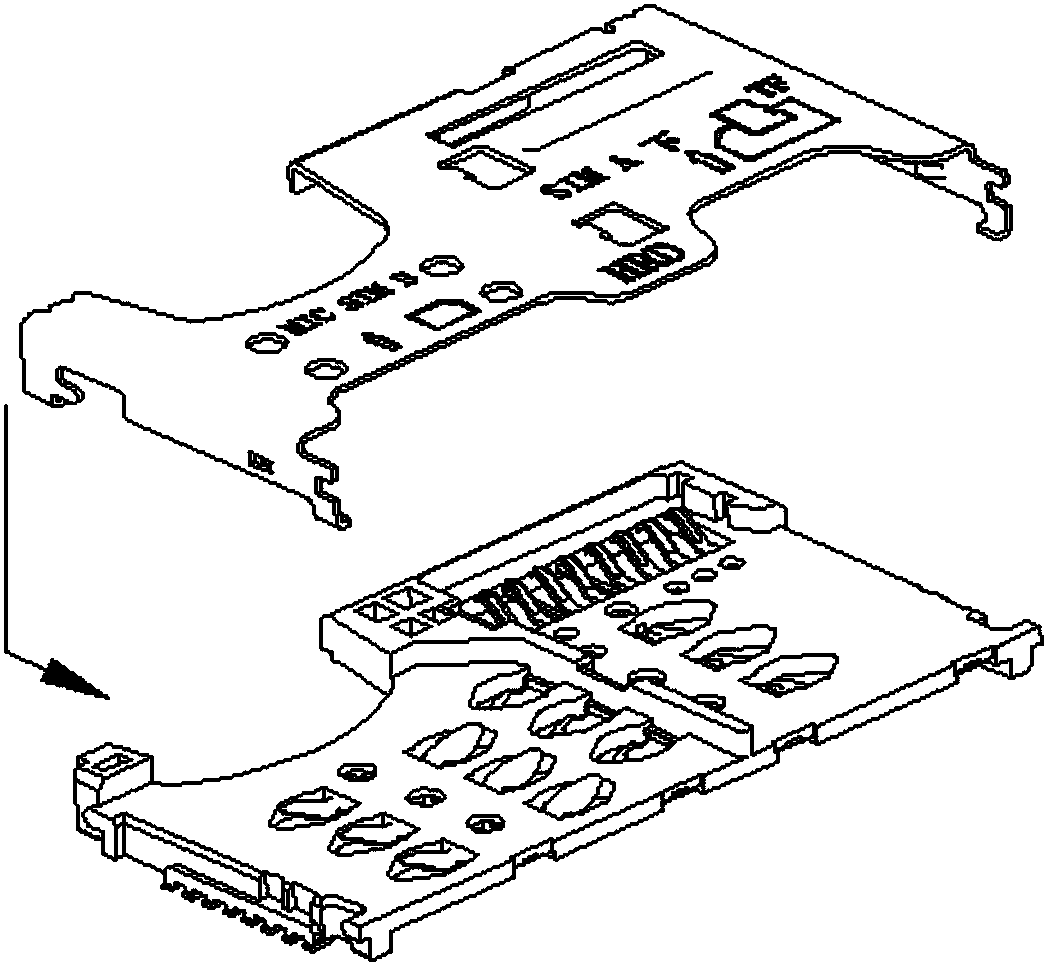

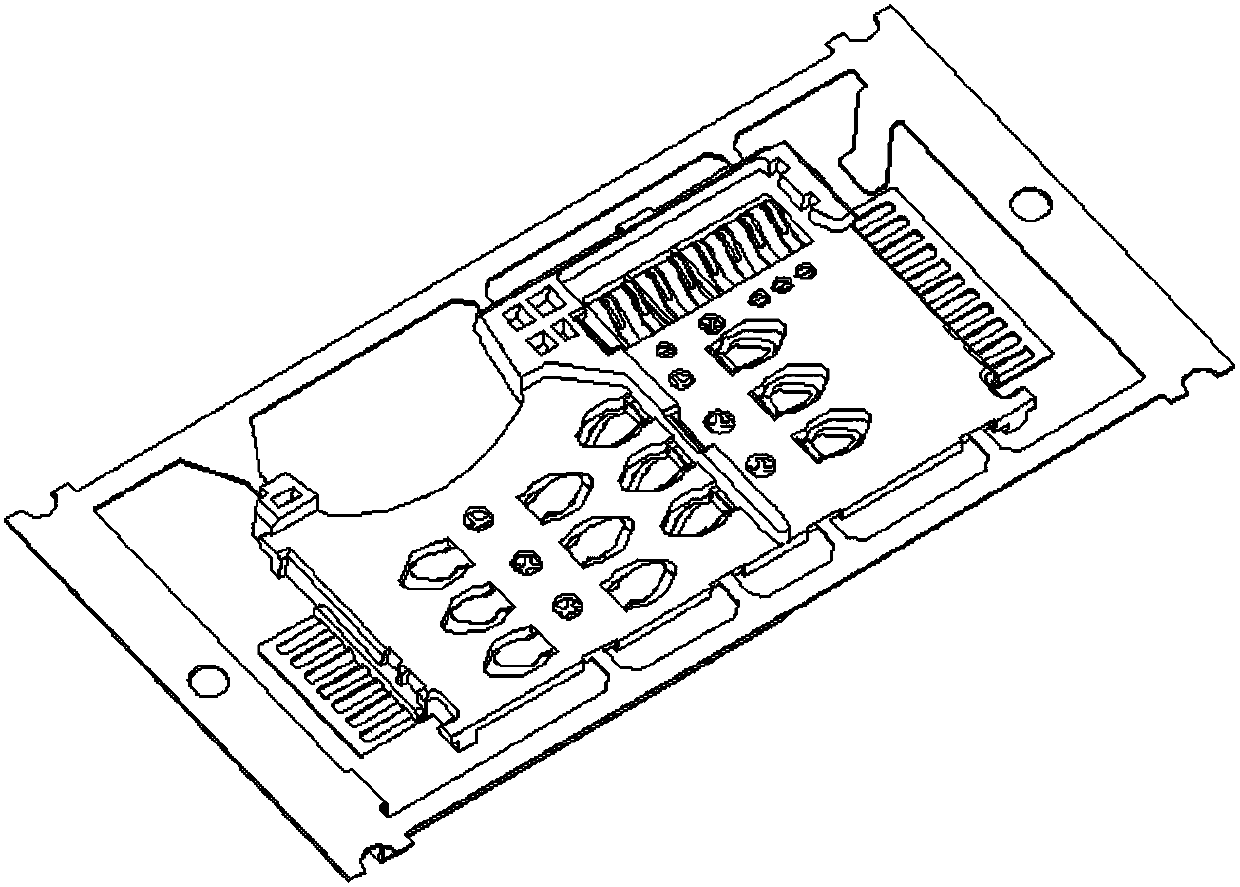

[0032] combine Figure 1-10 , the automatic assembly and detection equipment of the mobile phone deck of the present invention, it comprises:

[0033]The first working cabinet 10 and the second working cabinet 11, the first working cabinet 10 is respectively provided with the main body feeding and detection device 5, the shell feeding device 9 and the automatic assembly device 6, and the second working cabinet 11 is respectively provided with the finished product transfer The device 7, the finished product detection device 8 and the tape packaging device 12, the main body feeding and testing device 5 and the shell feeding device 9 are respectively connected with the automatic assembly device 6, and the automatic assembly device 6 is sequentially connected with the finished product detection device 8 through the finished product transfer device 7 , braiding and packaging device 12 are connected, wherein, the main body feeding and testing device 5, the shell feeding device 9 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com