Method for processing organosilicon waste water

A treatment method, silicone technology, applied in biological water/sewage treatment, neutralized water/sewage treatment, multi-stage water/sewage treatment, etc., can solve problems such as strong acidity, unsatisfactory effect, and high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

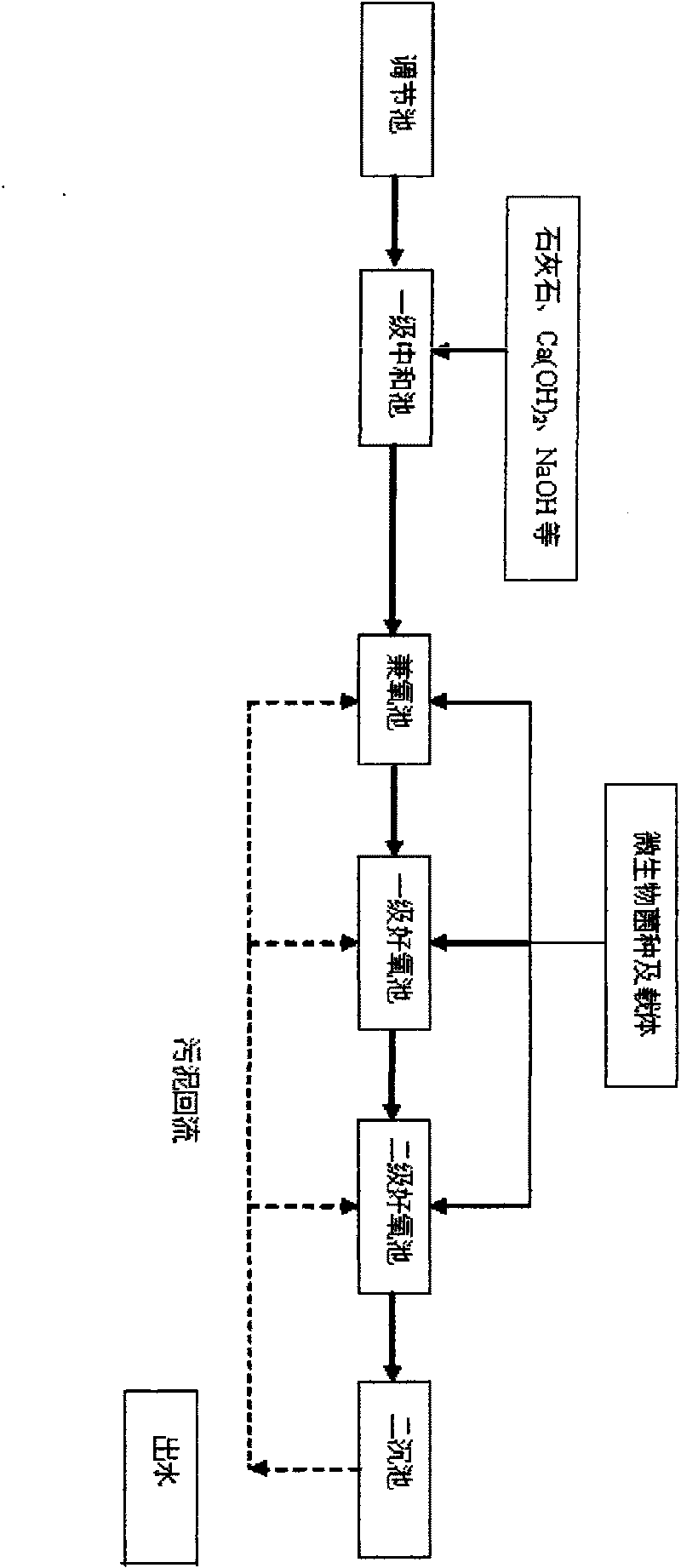

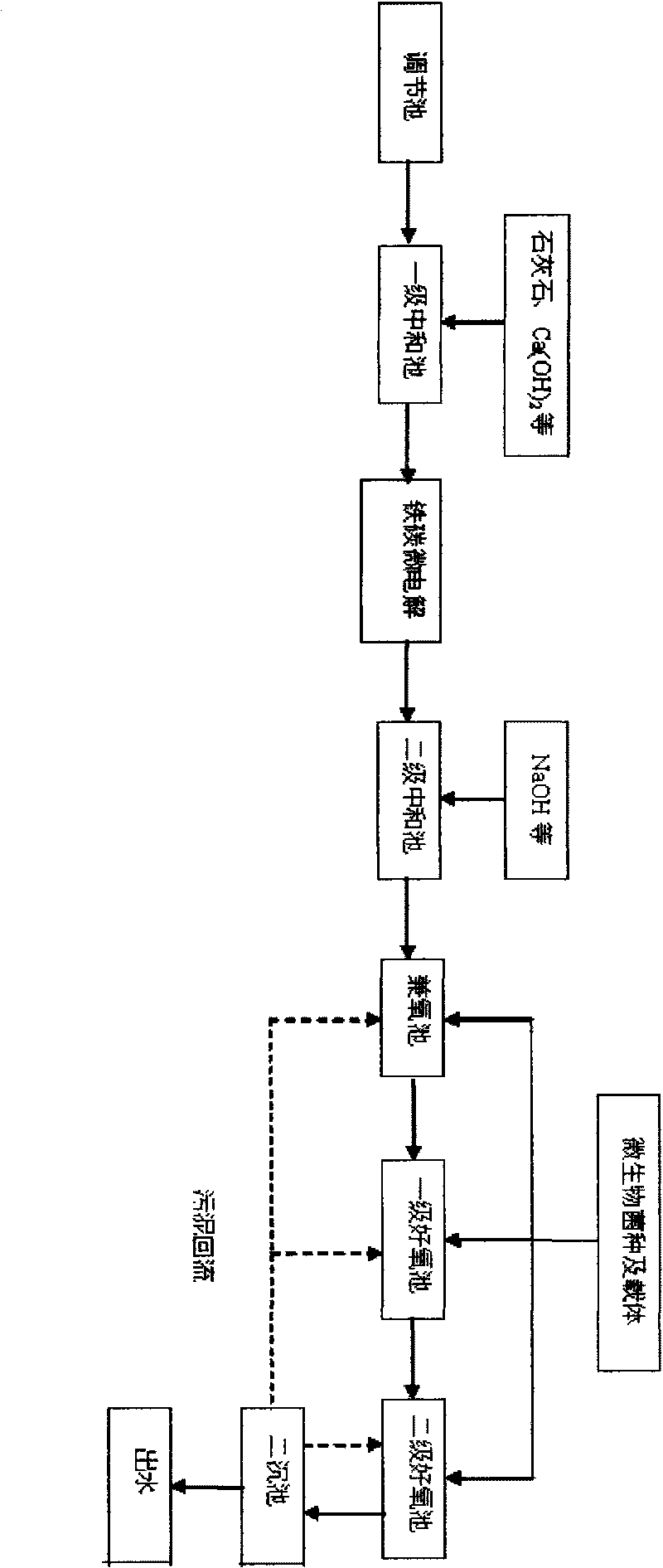

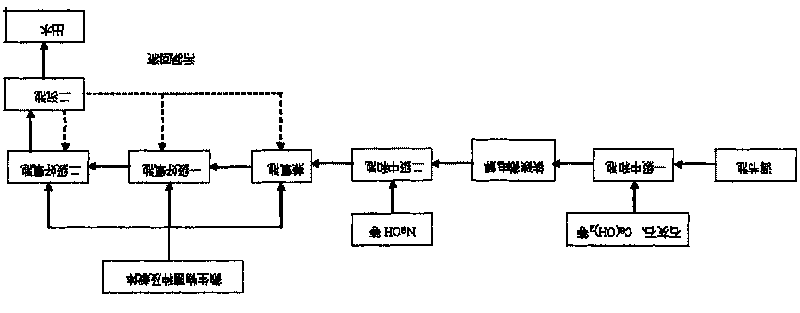

[0035] Such as figure 2 As shown, the organic silicon production wastewater first enters the regulating tank to adjust the water quality and quantity, and then enters the primary neutralization tank after being adjusted in the regulating tank, adding limestone, Ca(OH) 2 Neutralize the sediment, the supernatant overflows to the iron-carbon micro-electrolysis reaction area, aerates and stirs to make it fully mix and react with the filler in the reactor, the effluent enters the secondary neutralization tank for pH adjustment, and the effluent enters the biochemical processing unit. Wherein, COD removal rate of each unit = (influent COD of each unit - effluent COD of each unit) / influent COD of each unit.

[0036] 1. Adopt the organosilicon wastewater used in Comparative Example 1, adjust the organosilicon wastewater with the adjustment tank, the BOD5 / COD of the adjusted organosilicon wastewater obtained is 0.01, and the specific water quality data are the same as in Table 1;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com