Preparation technology of waterproof roll material with long serivce life

A technology of waterproofing membrane and preparation process, applied in the direction of lamination, layered products, synthetic resin layered products, etc., can solve the problems of short service life, harsh use environment, short product service life, etc. The effect of anti-ultraviolet ability, improving weather resistance and anti-ultraviolet ability, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

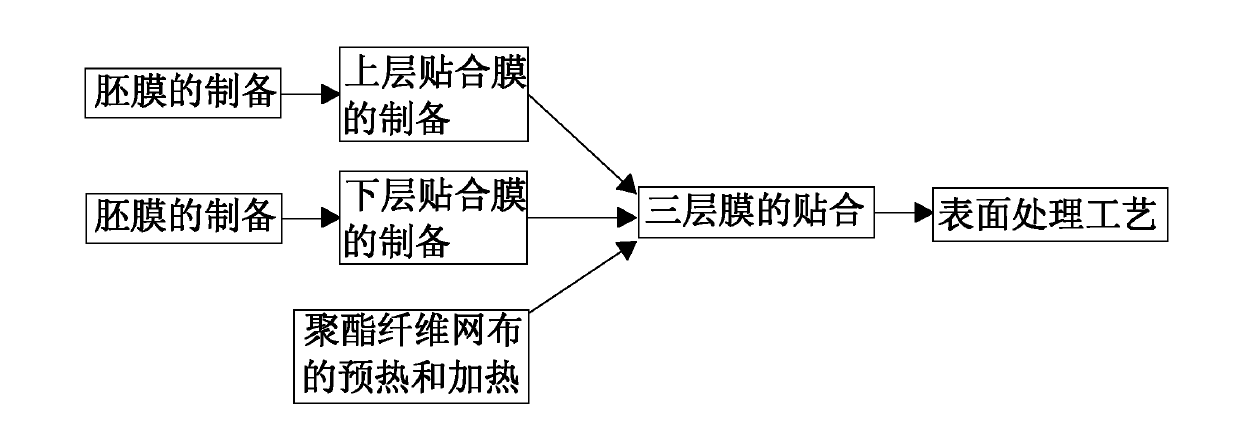

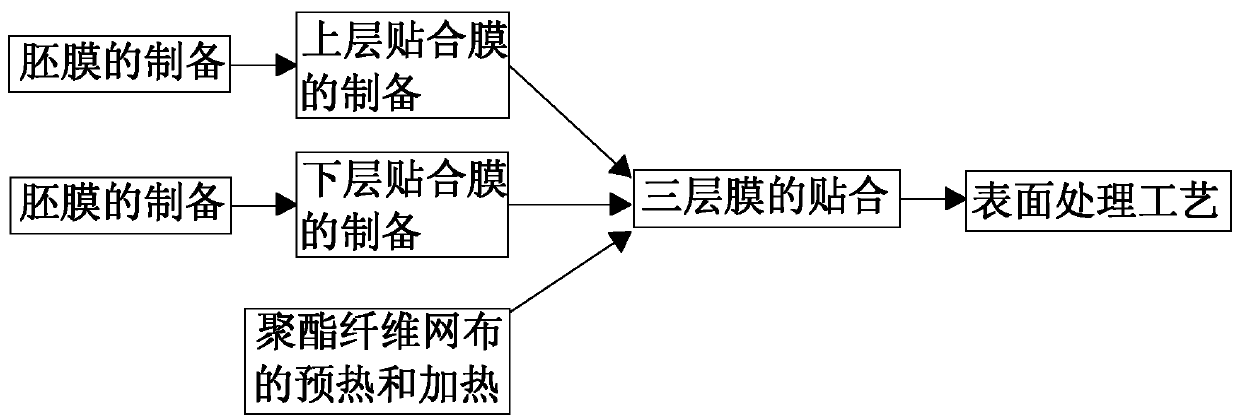

[0029] A preparation process of a waterproof coiled material with long service life, the preparation process comprises the following steps:

[0030] 1) Preparation of the embryonic membrane: Pour the raw material of the embryonic membrane into a calender molding machine and calender;

[0031] 2) Preparation of the upper laminated film: Send the two embryonic membranes prepared in step 1 to the laminating machine with a film sending rack, first preheat the embryonic membrane on a preheating roller at 140-160°C, and then preheat it at 160°C Heating on the heating roller at -175°C, the laminating roller is driven by air pressure to bond the two layers of germ film at the bonding place, the bonding pressure is 4-4.5Kg, the bonding temperature is 170-190°C, and the bonding roller speed is 5-16m / min; After cooling, use the same preheating conditions and heating conditions to bond with the third embryonic membrane to obtain the upper laminated film;

[0032] 3) Preparation of the lo...

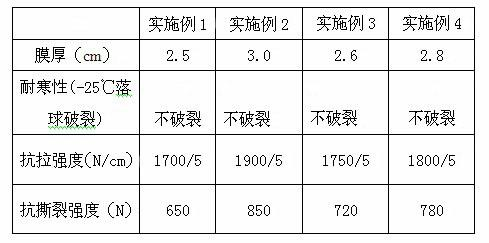

Embodiment 1

[0045] see figure 1 , a preparation process of a long service life waterproof membrane comprising the following steps:

[0046] 1) Preparation of the embryonic membrane: Pour the raw material of the embryonic membrane into a calendering machine and calender; the raw material for calendering of the embryonic membrane consists of the following materials in parts by weight:

[0047] Polyvinyl chloride (PVC) 100 parts

[0048] Flame retardant antimony trioxide 3 parts

[0049] Dioctyl phthalate (DOP) 55 parts

[0050] Barium zinc liquid stabilizer 3 parts

[0051] Dioctyl adipate (DOA) 15 parts.

[0052]2) Preparation of the upper laminated film: Send the two embryonic membranes prepared in step 1 to the laminating machine with a film sending rack, first preheat the embryonic membranes on a preheating roller at 140°C, and then preheat them on a preheating roller at 180°C Heat on the heating roller, drive the bonding roller with air pressure to bond the two layers of embryo f...

Embodiment 2

[0060] 1) Preparation of the embryonic membrane: Pour the raw material of the embryonic membrane into a calendering machine and calender; the raw material for calendering of the embryonic membrane consists of the following materials in parts by weight:

[0061] Polyvinyl chloride (PVC) 100 parts

[0062] Flame retardant antimony trioxide 5 parts

[0063] Magnesium hydroxide 10 parts

[0064] Dioctyl phthalate (DOP) 40 parts

[0065] Barium zinc liquid stabilizer 4 parts

[0066] Dioctyl adipate (DOA) 5 parts.

[0067] 2) Preparation of the upper laminated film: Send the two embryonic membranes prepared in step 1 to the laminating machine with a film sending rack, first preheat the embryonic membrane on a preheating roller at 160°C, and then preheat the embryonic membrane at 190°C Heating on the heating roller, using air pressure to drive the bonding roller to bond the two layers of embryo film at the bonding point, the bonding pressure is 4.5Kg, the bonding temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com