Process and equipment for pyrolyzing coking wastewater by utilizing dust-removed high temperature flue gas of converter

A technology for coking wastewater and high-temperature flue gas, which is applied in the field of iron and steel metallurgy and chemical industry, and can solve the problems of undiscovered coking wastewater and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

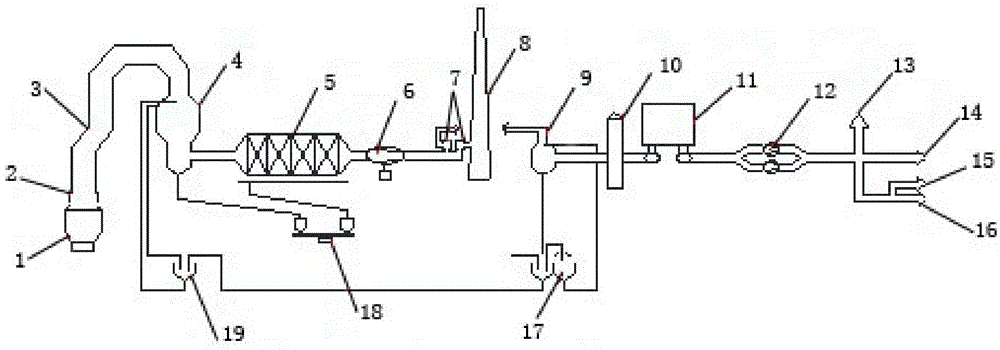

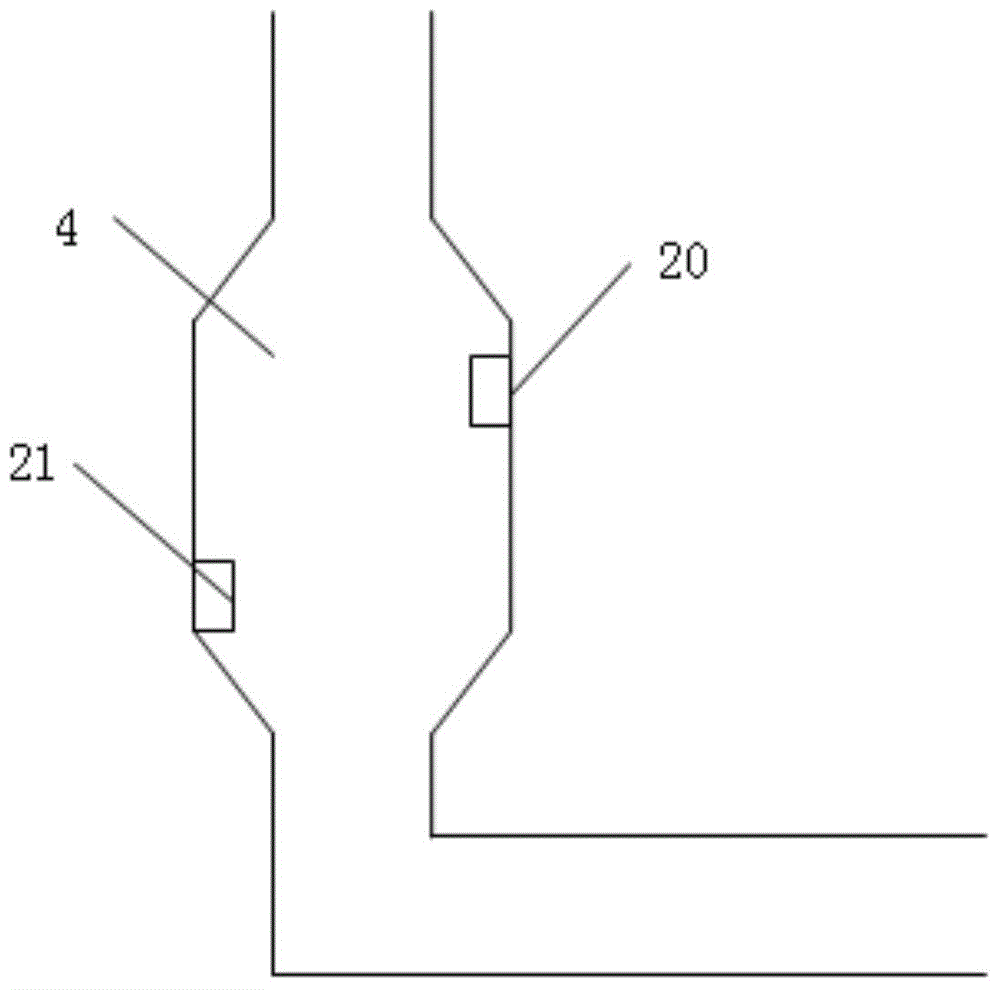

[0010] Technical scheme of the present invention is as follows:

[0011] A combination of equipment for pyrolyzing coking wastewater by using converter dedusting high-temperature flue gas, including waste heat boiler (3), evaporative cooler (4), electric dust collector (5), ID fan (6), coking wastewater injection system (19) , it is characterized in that waste heat boiler (3), evaporative cooler (4), electric precipitator (5), ID fan (6) are sequentially connected, coking wastewater injection system (19) is connected with evaporative cooler (4); The cooler (4) is used to atomize the coking waste water and carry out the pyrolysis reaction under the action of the catalyst.

[0012] The coking wastewater injection system is connected to the evaporative cooler, which makes full use of the temperature of the flue gas in the evaporative cooler in the converter dedusting equipment to pyrolyze the organic matter in the untreated coking wastewater.

[0013] Preferably, the combination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com