Microorganism concentration process and device

一种浓集、聚合物的技术,应用在捕获或浓集微生物领域,能够解决昂贵、速度慢等问题,达到简单成本、低成本、高抗阻塞性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0129] Objects and advantages of this invention are further illustrated by the following examples, but the particular materials and amounts thereof recited in these examples, as well as other conditions and details, should not be construed to unduly limit this invention. All parts, percentages, ratios, etc. in the following examples are by weight unless otherwise indicated. Solvents and other reagents were obtained from Sigma-Aldrich Chemical Company, Milwaukee, WI unless otherwise noted. All microbial cultures were purchased from the American Type Culture Collection (ATCC; Manassas, VA) in Manassas, VA. Unless otherwise indicated, experimental results are the average of 2 tests. Overnight cultures were prepared by streaking selected microorganisms onto tryptic soy agar plates followed by overnight incubation at 37°C. All microbial counts were performed according to standard microbiological enumeration methods for colony forming units and counts are approximate.

[0130] ...

example 1-17 and comparative example C1-C4

[0178] Examples 1-17 and Comparative Examples C1-C4: Preparation of concentration devices 1-17 and C1-C4

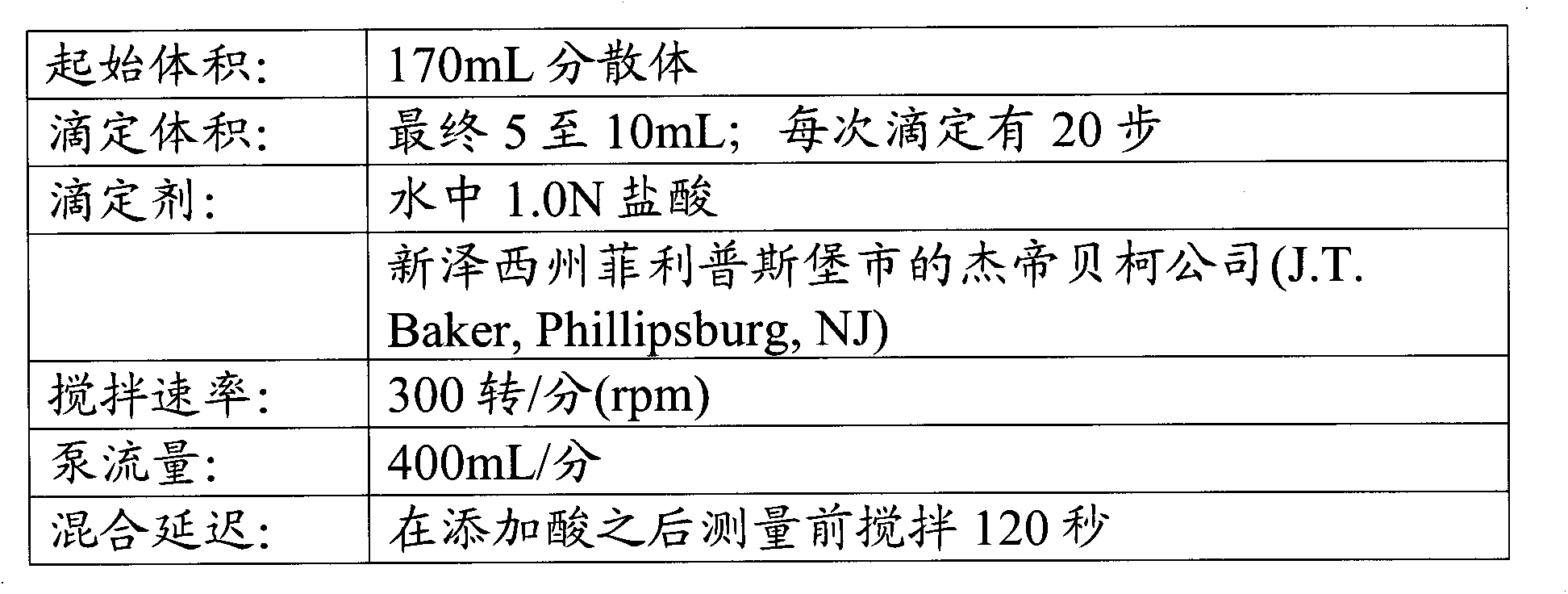

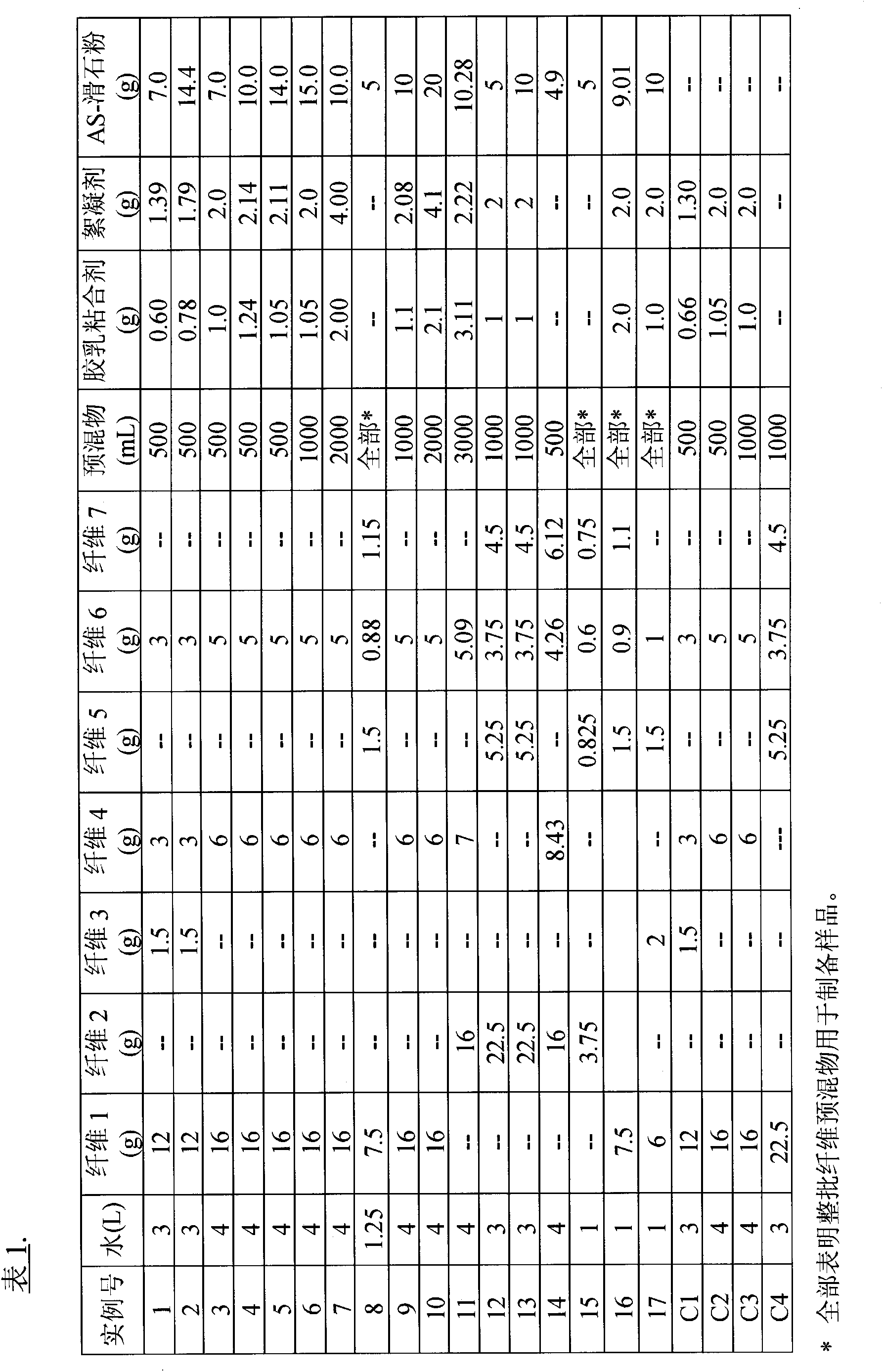

[0179] Fiber premixes were prepared having the fiber and water compositions shown in Table 1. Each fiber premix was prepared by first mixing the fibrillated fiber (fiber 1 or fiber 2) with the indicated amount of tap water in a 4L blender ((Waring Commercial Heavy Duty Blender, Model 37BL84) ) blended at medium speed for 90 seconds. Check that the fibers proceed to ensure they are evenly dispersed without knots or clumps, and blend them further if necessary to break up any clumps. Then add the other indicated fibers Further blending was carried out and the indicated amount of premix was added to a stainless steel beaker and an impeller mixer (Stedfast Stirrer Model SL2400, Fisher Scientific, available from VWR, West Chester, Pennsylvania (VWR, West Chester, PA)) was mixed at speed setting 4 for five minutes. When used, the latex binder was dispersed in approximately 25...

example 16

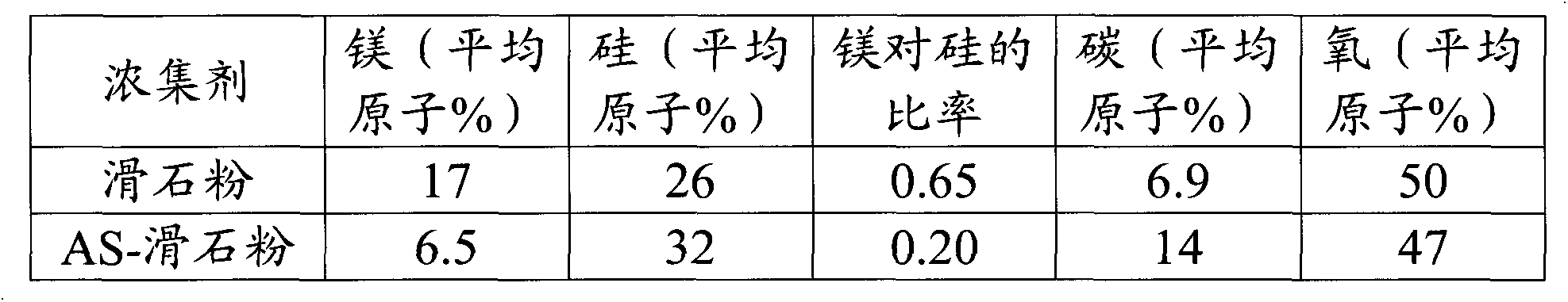

[0183] Example 16 was prepared essentially by the procedure described above, except that AS-talc particles were added to the fiber premix prior to the addition of the latex binder.

[0184] The resulting porous fibrous nonwoven matrix was sealed in a plastic bag and irradiated with 0.5 kGy / hr of gamma radiation at a total dose of 4 kGy for 8 hours, or autoclaved at 121° C. for 15 minutes to sterilize the matrix. Square sample matrices (measured 20 cm x 20 cm (8 in x 8 in)) were cut from the matrices of the selected examples, weighed and solids retention values were determined for these sample matrices, as shown in Table 2 out.

[0185]

[0186] Table 2 .

[0187] instance number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com