A method for converting heavy oil into light oil using a suspended bed hydrogenation process

A suspended bed, light oil technology, applied in the field of heavy oil hydrogenation, can solve the problem of high sulfur and nitrogen content, and achieve the effects of reducing coking rate, reducing difficulty and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

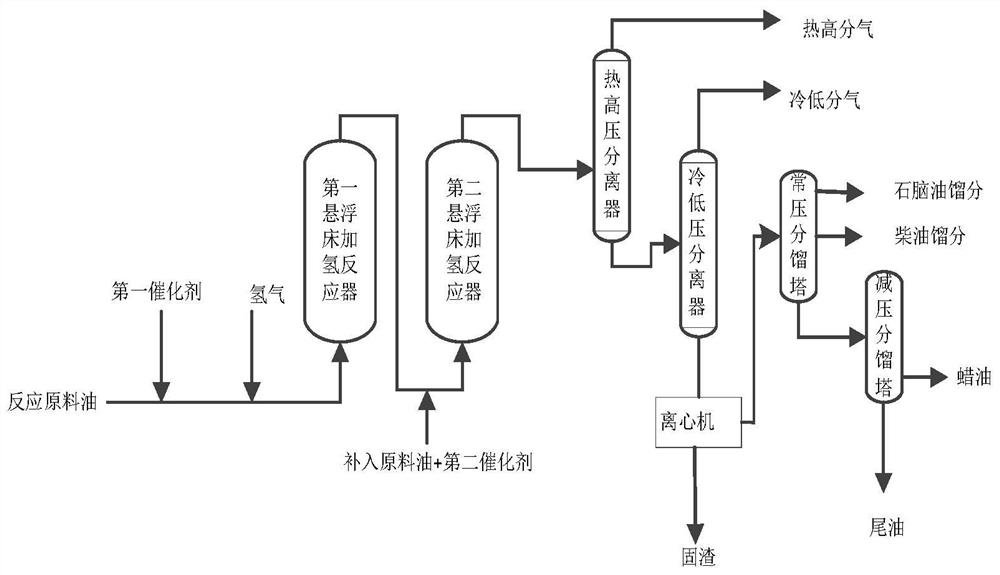

Method used

Image

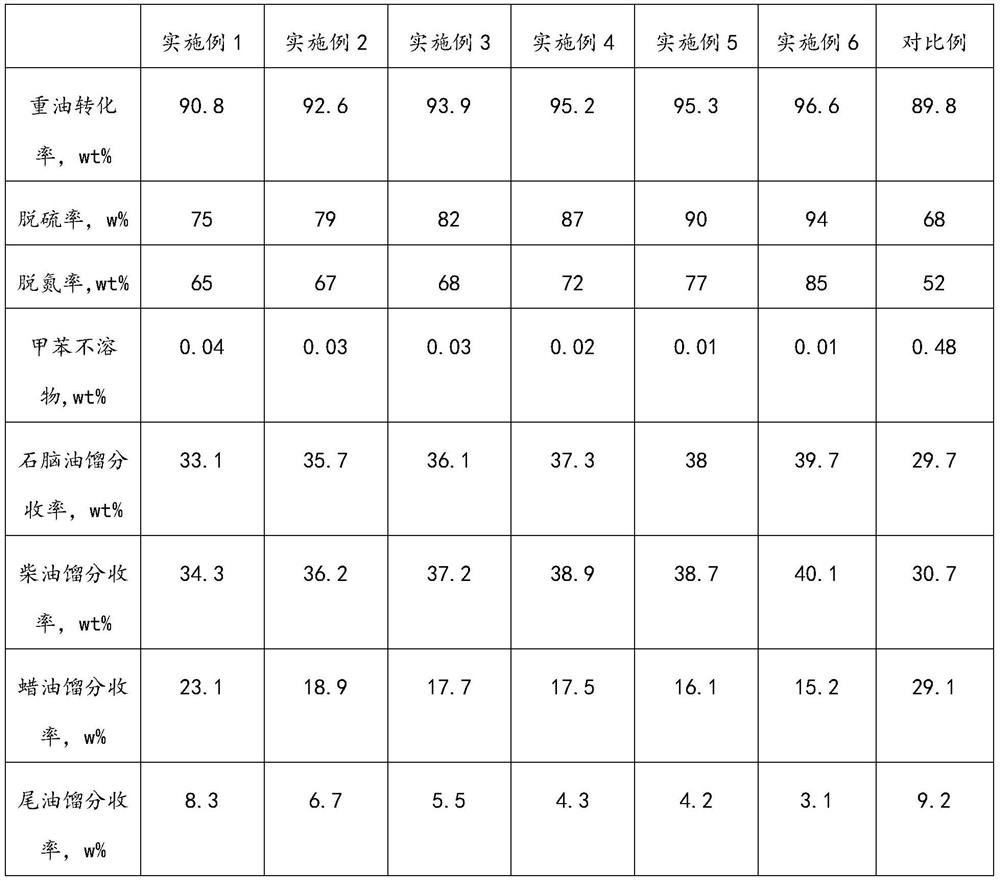

Examples

Embodiment 1

[0037] This embodiment provides a method for converting heavy oil into light oil using a suspended bed hydrogenation process, comprising the following steps:

[0038] (1) After the reaction raw material oil, the first hydrogenation catalyst and hydrogen are mixed, they are transported to the first suspension bed hydrogenation reactor, and the operating pressure in the first suspension bed hydrogenation reactor is controlled to be 12MPa, and the temperature is 460°C. The liquid hourly space velocity is 0.8h -1 , The volume ratio of hydrogen to oil is 700 to carry out the first catalytic hydrogenation reaction;

[0039] The first hydrogenation catalyst includes ferrous sulfate and sulfur powder; the first hydrogenation catalyst is in the reaction raw material oil, and the concentration is 10 μ g / g in terms of metal;

[0040] (2) The product and catalyst slurry from the first suspended bed hydrogenation reactor are sent into the second suspended bed hydrogenation reactor, and th...

Embodiment 2

[0044] This embodiment provides a method for converting heavy oil into light oil using a suspended bed hydrogenation process, comprising the following steps:

[0045] (1) if figure 1 As shown, the first suspended bed hydrogenation reactor and the second suspended bed hydrogenation reactor are arranged in series;

[0046] The reaction raw material oil, the first hydrogenation catalyst and hydrogen are sent to the first suspension bed hydrogenation reactor, and the operating pressure in the first suspension bed hydrogenation reactor is controlled to be 22MPa, the temperature is 390°C, and the liquid hourly space velocity is 1.4h -1 , The volume ratio of hydrogen to oil is 2000 to carry out the first catalytic hydrogenation reaction;

[0047] The first hydrogenation catalyst includes sodium nitrate and sulfur powder; the concentration of the first hydrogenation catalyst in the reaction raw material oil is 1500 μg / g in terms of metal;

[0048] (2) The product and catalyst slurry...

Embodiment 3

[0052] This embodiment provides a method for converting heavy oil into light oil using a suspended bed hydrogenation process, comprising the following steps:

[0053] (1) After the reaction raw material oil, the first hydrogenation catalyst and hydrogen are mixed, they are transported to the first suspension bed hydrogenation reactor, and the operating pressure in the first suspension bed hydrogenation reactor is controlled to be 18MPa, and the temperature is 410°C. The liquid hourly space velocity is 1h -1 , The volume ratio of hydrogen to oil is 1600 to carry out the first catalytic hydrogenation reaction;

[0054] The first hydrogenation catalyst includes chromium nitrate and sulfur powder; the concentration of the first hydrogenation catalyst in the reaction raw material oil is 500 μg / g in terms of metal;

[0055] (2) The product and catalyst slurry from the first suspended bed hydrogenation reactor are sent into the second suspended bed hydrogenation reactor, and the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com