Device and process for recycling and treating hydrogen sulfide-containing chemical acid waste gas

A technology for acidic waste gas and hydrogen sulfide, applied in sulfate preparations, incinerators, chemical instruments and methods, etc., to achieve the effects of waste gas treatment and heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

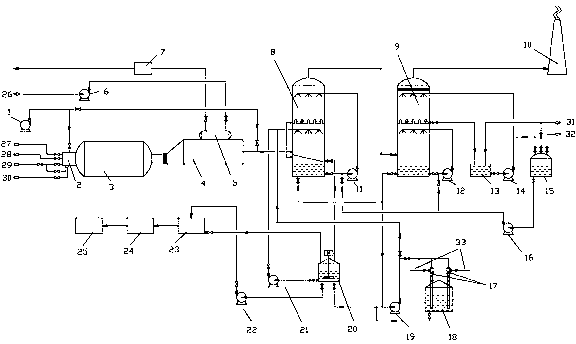

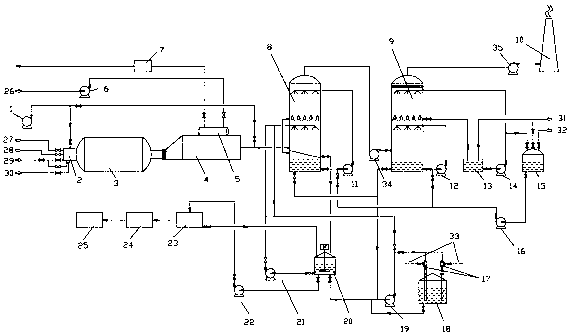

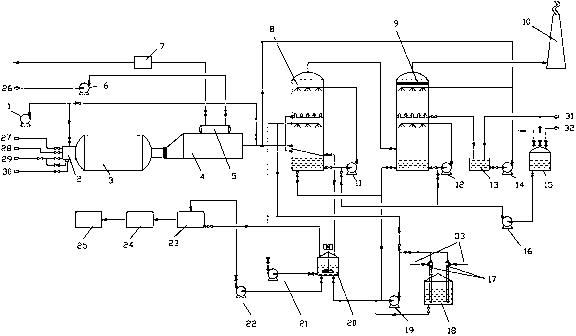

[0033] Such as figure 1 As shown, a hydrogen sulfide-containing chemical acid waste gas recovery and treatment device and process, the device includes a blower 1, a burner 2, an incinerator 3, a waste heat utilization boiler 4, a steam drum 5, a primary absorption tower 8, Secondary absorption tower 9, washing tank 13, lye tank 15, oxidation tank 18, slurry tank 20, crystallization separation system 23, drying system 24, packaging system 25 and various centrifugal pumps.

[0034] The burner 2, the incinerator 3, the waste heat utilization boiler 4, the steam drum 5, the boiler feed water pump 6, and the decompression device 7 are configured to ignite the acid waste gas containing hydrogen sulfide, completely incinerate and convert it into a high-temperature gas rich in sulfur dioxide, A conversion system that cools high-temperature gas and recovers heat.

[0035] The boiler feed water pump 6 communicates with the steam drum 5 and the decompression device 7 , and the boiler wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com