Pebble falling preventing compartment of building gravel carrier vehicle

A technology of transport vehicles and carriages, applied in the field of carriages, can solve the problems of poor performance, life-threatening of drivers, falling to the ground, etc., and achieve the effect of ensuring life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

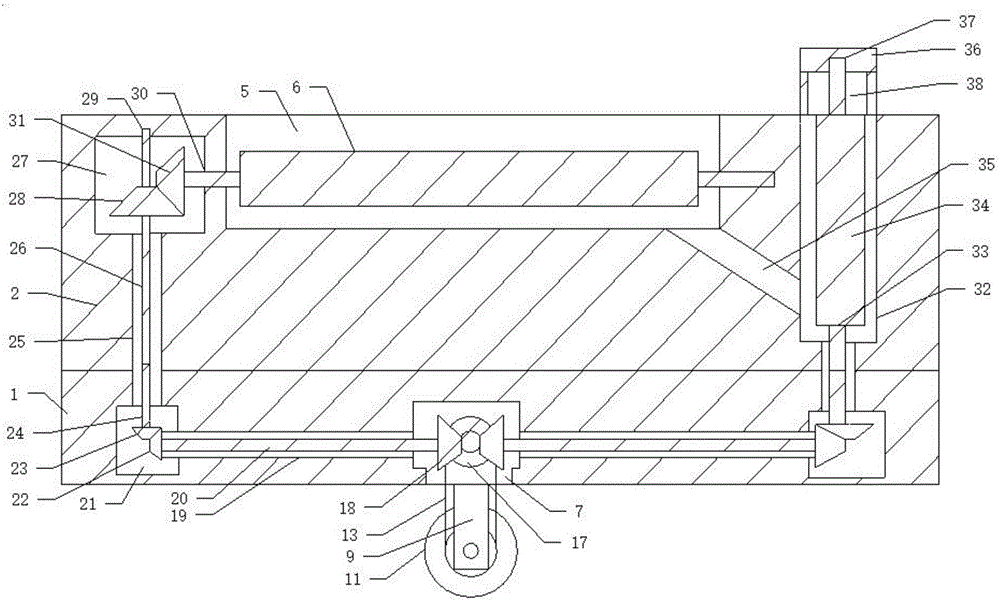

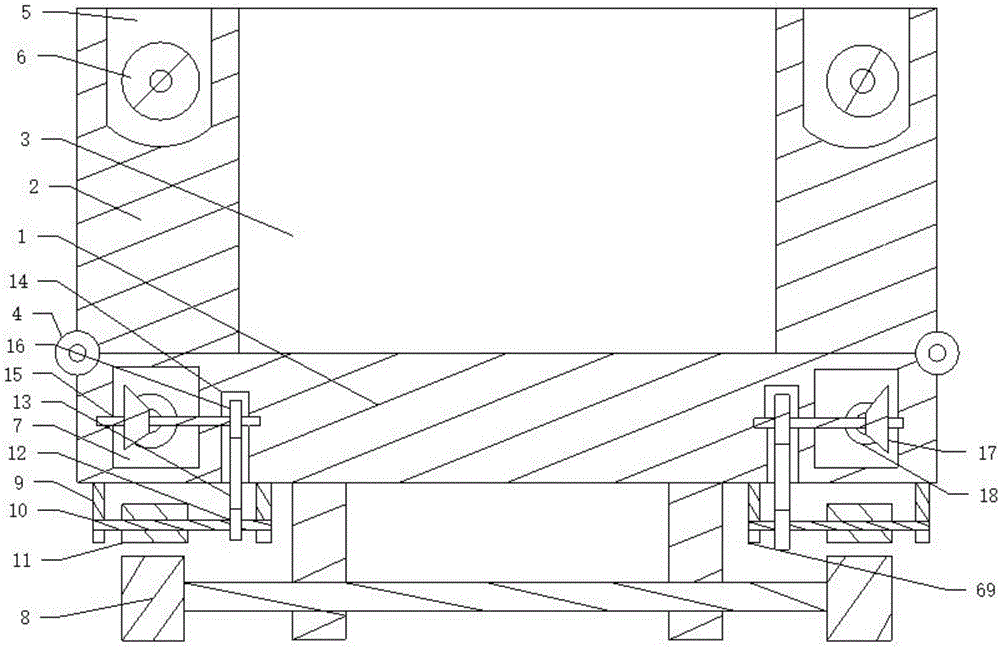

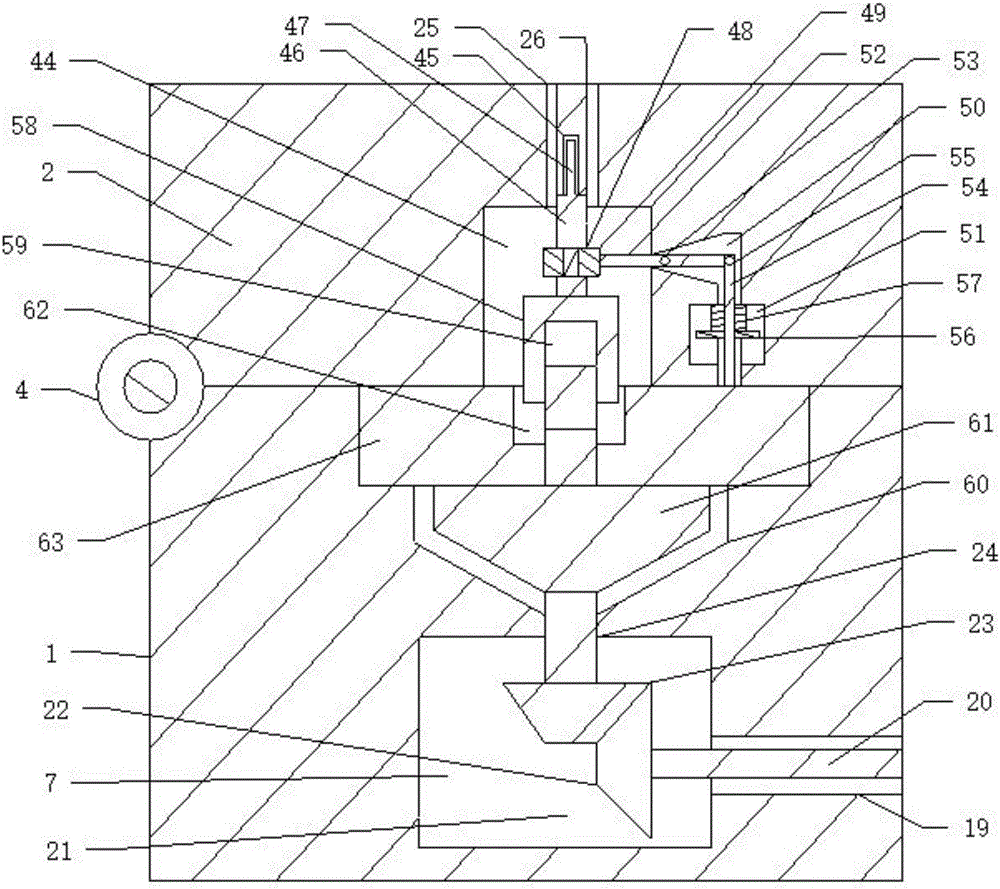

[0025] Such as Figure 1 to Figure 5 As shown, an anti-stone falling carriage of a construction sand and gravel transport vehicle includes a bottom plate 1, a carriage side plate 2 is connected to both sides of the bottom plate 1, and the carriage side plate 2 and the bottom plate 1 They are respectively connected by a hinge 4, the two sides of the bottom plate 1 also include rotating tires 8, and two sides of the bottom plate 1 are respectively provided with a rotating drive wheel 11, and the drive wheel 11 is connected to the two sides respectively. The tires 8 are connected correspondingly, a first inner cavity 7 is respectively provided on both sides of the bottom plate 1, and a first bevel gear 17 is respectively provided in the first inner cavity 7, and the driving wheels 11 on both sides respectively drive the When the first bevel gear 17 rotates, two second inner cavities 21 corresponding to the first inner cavity 7 are respectively provided on both sides of the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com