Electrostatic spray coating system

A fog coating and electrostatic technology, applied in electrostatic spraying devices, coatings, liquid spraying equipment, etc., can solve the problems of low material use efficiency, uneven coating, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

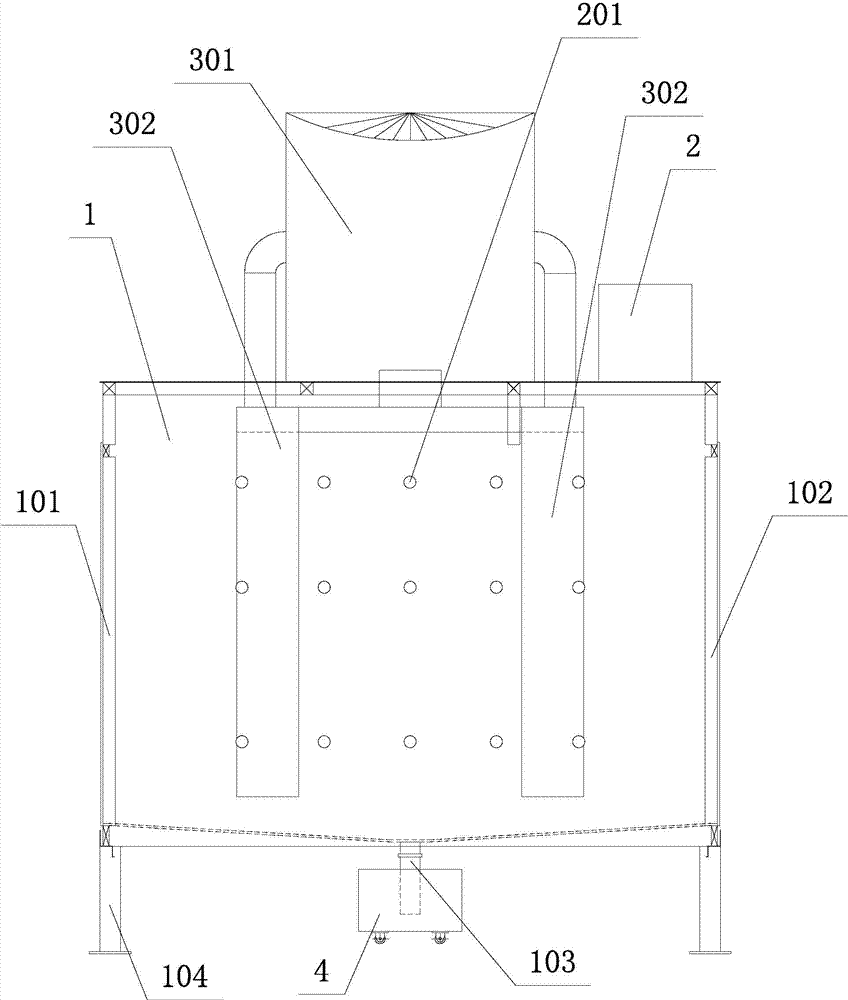

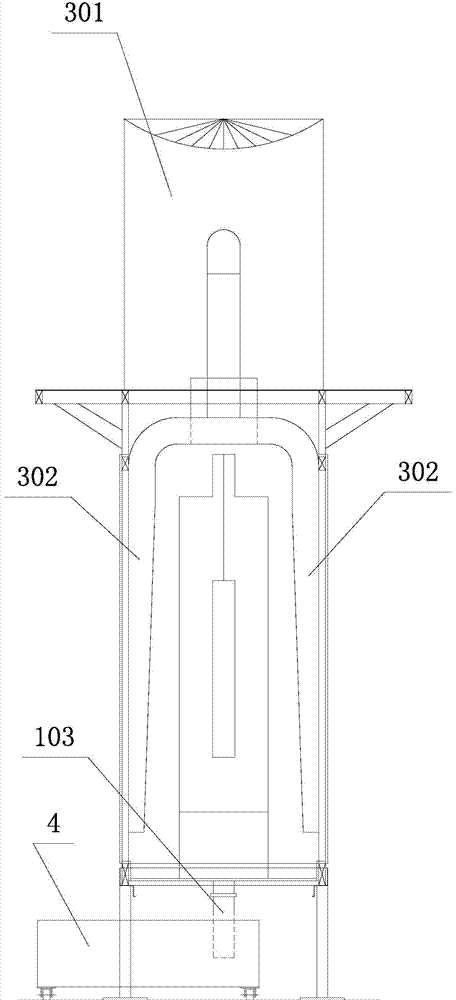

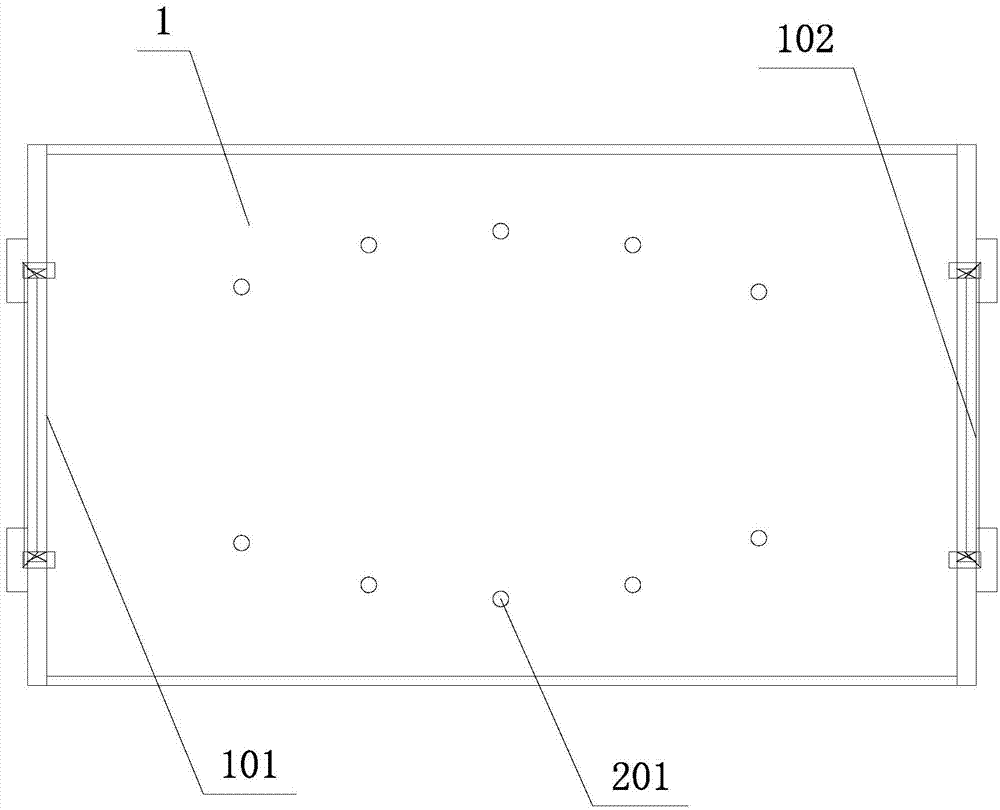

[0025] Refer to Figure 1 ~ Figure 3 , The present invention provides an electrostatic fog coating system, including a work shed body 1, a fog coating system, an electrostatic generator, a recovery system and a loading device;

[0026] The working shed 1 is used to provide a fog coating place and load other components. It is a box structure with supporting feet 104 at the bottom; a fog coating cavity is formed in the working shed 1, and the fog coating process is carried out in the fog coating cavity. At the same time, both sides of the work shed 1 are provided with a feed port 101 and a discharge port 102 communicating with the mist coating chamber; the workpiece to be coated enters the mist coating chamber from the feed port for mist coating, and after the coating is completed, the material is discharged Discharge the material from the mouth and enter the next process. In order to improve the sealing and avoid the leakage of atomized particles, air curtains are installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com