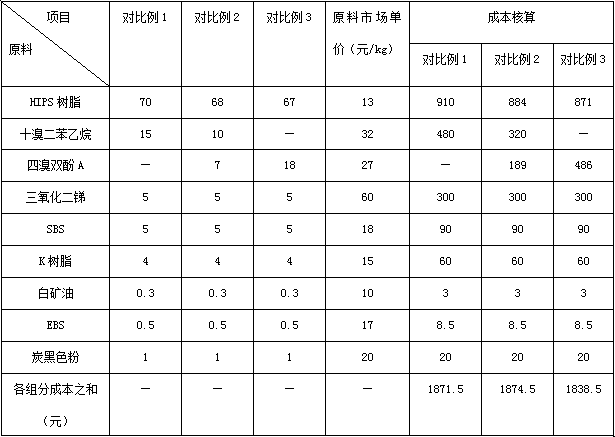

Halogen-free flame retardant HIPS (High Impact Polystyrene) plastic modified material and preparation method thereof

A modified material and plastic technology, applied in the field of halogen-free flame retardant HIPS plastic modified material and its preparation, can solve the problem of tensile strength, bending strength, impact strength, thermal deformation temperature drop, TV casing resistance of modified materials. Problems such as poor impact performance and physical and mechanical properties of materials, etc., achieve the effects of long service life, great environmental protection benefits, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

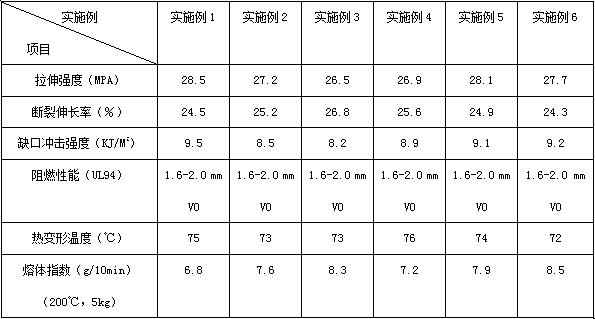

Examples

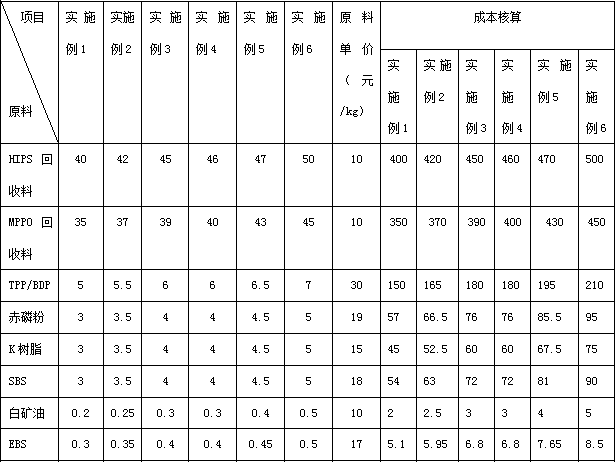

Embodiment 1

[0089] A halogen-free flame-retardant HIPS plastic modified material, which is composed of the following raw materials in parts by weight: 40 parts of HIPS, 35 parts of MPPO, 5 parts of triphenyl phosphate (TPP), 3 parts of red phosphorus powder, 3 parts of K resin, 3 parts of SBS, 0.3 parts of vinyl bis stearamide (EBS), 0.2 parts of white mineral oil, 0.5 parts of carbon black powder.

[0090] The preparation method of the halogen-free flame-retardant HIPS plastic modified material of the present embodiment, it is made up of the following steps:

[0091] (1) Put MPPO and 3 parts of triphenyl phosphate (TPP) into a twin-screw extruder or a single-screw extruder in parts by weight, and extrude and granulate at a temperature of 240°C to obtain mixture I;

[0092] (2) Put HIPS, red phosphorus powder, K resin, SBS, lubricant, white mineral oil, carbon black powder, remaining triphenyl phosphate (TPP) and the mixture I prepared in step (1) into high-speed Mix and stir evenly in a...

Embodiment 2

[0095] A halogen-free flame-retardant HIPS plastic modified material, which consists of the following raw materials in parts by weight: 42 parts of HIPS, 37 parts of MPPO, 5.5 parts of bisphenol A-bis(diphenyl phosphate) (BDP), red phosphorus powder 3.5 parts, K resin 3.5 parts, SBS 3.5 parts, vinyl bis stearamide (EBS) 0.35 parts, white mineral oil 0.25 parts, carbon black powder 0.8 parts.

[0096] The preparation method of the halogen-free flame-retardant HIPS plastic modified material of the present embodiment, it is made up of the following steps:

[0097] (1) Put MPPO and 3 parts of bisphenol A-bis(diphenyl phosphate) (BDP) into a twin-screw extruder or a single-screw extruder by weight, extrude and granulate at a temperature of 245°C to produce Obtain mixture I;

[0098] (2) HIPS, red phosphorus powder, K resin, SBS, lubricant, white mineral oil, carbon black powder, remaining bisphenol A-bis(diphenyl phosphate) (BDP) and step (1 ) the prepared mixture I was put into ...

Embodiment 3

[0101] A halogen-free flame-retardant HIPS plastic modified material, which is composed of the following raw materials in parts by weight: 45 parts of HIPS, 39 parts of MPPO, triphenyl phosphate (TPP) and bisphenol A-bis(diphenyl phosphate) ( BDP) mixture 6 parts, red phosphorus powder 4 parts, K resin 4 parts, SBS 4 parts, vinyl bis stearamide (EBS) 0.4 parts, white mineral oil 0.3 parts, carbon black powder 1 part.

[0102] The preparation method of the halogen-free flame-retardant HIPS plastic modified material of the present embodiment, it is made up of the following steps:

[0103](1) Put the mixture of MPPO and 3 parts of triphenyl phosphate (TPP) and bisphenol A-bis(diphenyl phosphate) (BDP) into the twin-screw master machine or single-screw master machine in parts by weight, at 250 Extrude and granulate at a temperature of ℃ to prepare mixture I;

[0104] (2) Mix HIPS, red phosphorus powder, K resin, SBS, lubricant, white mineral oil, carbon black powder, remaining tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com