Coal ash biological filter material and preparation method of coal ash biological filter material

A technology of biological filter material and fly ash, which is applied in the direction of ceramic products, other household utensils, solid waste removal, etc., and can solve the problems of unreachable solid waste, raw material ball fried ball, clay ceramsite with low specific surface area, etc. , to increase the specific surface area of the filter material, improve the quality and porosity, and facilitate the growth of biological bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

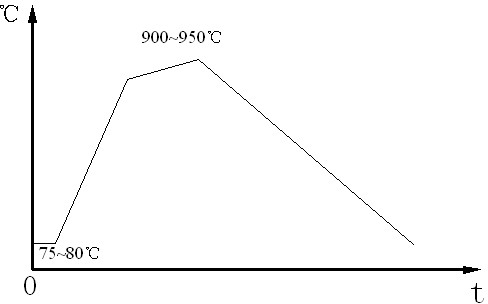

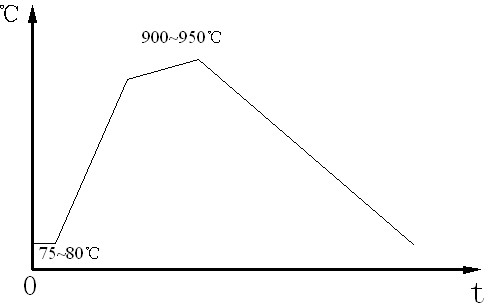

Image

Examples

Embodiment 1

[0023] The raw material composition and mass percentage of the fly ash biological filter material of this embodiment are:

[0024] Fly ash 86%

[0025] Clay coal gangue 3%

[0026] Binder 10%

[0027] Expansion agent 1%.

[0028] In this embodiment, the clay coal gangue has a carbon content of more than 10% and a particle size of less than 120 mesh; coal gangue is a solid waste discharged during coal mining, tunneling, and coal washing. The present invention uses carbon content Coal gangue with a percentage of more than 10% and clay-like nature can increase its activity by grinding and act as an internal combustion agent and binder for fly ash sintered ceramsite.

[0029] In this embodiment, the binder is composed of one or more of municipal sludge, sludge, electrolytic ash, slag, steel slag, and magnetic separation sludge; the binder filling enhances the activity of coarse-particle fly ash , Enhance the strength of the filter material.

[0030] In this embodiment, the expansion agent i...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that the raw material composition and mass percentage of the fly ash biological filter material of this embodiment are:

[0039] Fly ash 88.5%

[0040] Clay coal gangue 10%

[0041] Binder 0.5%

[0042] Expansion agent 1%.

Embodiment 3

[0044] The difference between this embodiment and Embodiment 1 is that the raw material composition and mass percentage of the fly ash biological filter material of this embodiment are:

[0045] Fly ash 90%

[0046] Clay coal gangue 4%

[0047] Binder 3%

[0048] Expansion agent 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com