Process for treating nitrogen-containing wastewater by ion exchange and reclaiming ammonium nitrate

A technology of ion exchange and ammonium nitrate, which is applied in the field of ion exchange treatment of nitrogen-containing wastewater and recovery of ammonium nitrate, can solve the problems of low low-temperature nitrification efficiency, complex operation management, secondary pollution, etc., and achieve low treatment efficiency, flexible operation management, Realize the effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

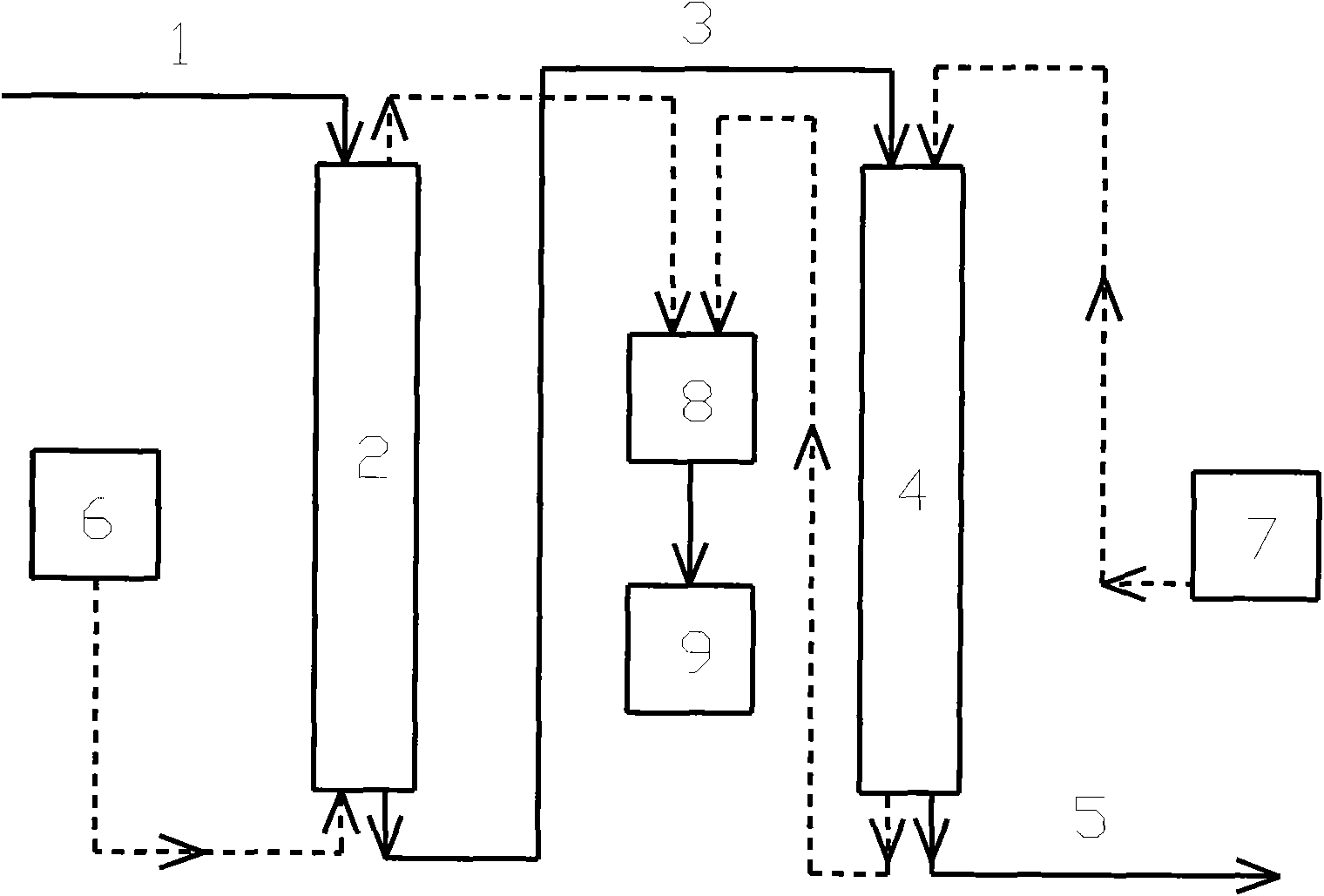

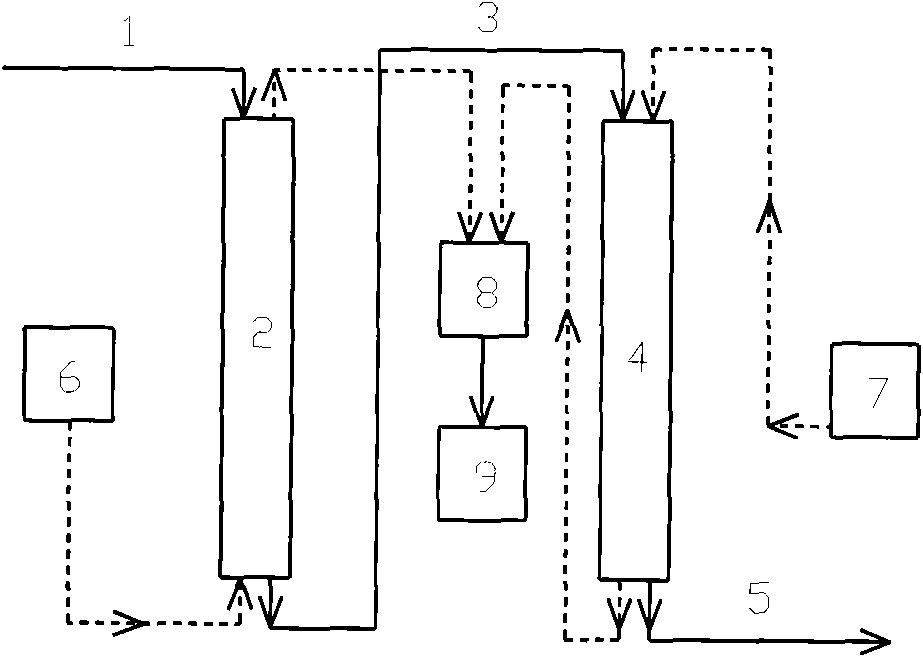

Method used

Image

Examples

Embodiment approach 1

[0025] Ion exchange resin adopts strongly acidic cation exchange resin D001 and weakly basic anion exchange resin D370.

[0026] Strongly acidic cation exchanger: run at a water temperature of 15°C, the pH value of the influent water is 6; the exchange flow rate is 4m / h, the concentration of the nitric acid regeneration solution is 10%, the regeneration flow rate is 4m / h, and the forward and backwash flow rates are 15m / h. The time for forward and backwashing is 20 minutes;

[0027] Weakly alkaline anion exchanger: run at a water temperature of 15°C, the pH value of the feed water is 6; the exchange flow rate is 4m / h, the concentration of the ammonia water regeneration solution is 5%, the regeneration flow rate is 4m / h, and the forward and backwash flow rates are 15m / h , The positive and negative washing time is 20 minutes.

Embodiment approach 2

[0029] The ion exchange resin adopts strongly acidic cation exchange resin D001 and weakly basic anion exchange resin D370.

[0030]Strongly acidic cation exchanger: run at a water temperature of 15°C, the pH value of the influent water is 7; the exchange flow rate is 4m / h, the concentration of the nitric acid regeneration solution is 20%, the regeneration flow rate is 4m / h, and the forward and backwash flow rates are 15m / h. The time for forward and backwashing is 20 minutes;

[0031] Weakly alkaline anion exchanger: run at a water temperature of 15°C, the pH value of the influent is 7; the exchange flow rate is 4m / h, the concentration of the ammonia water regeneration solution is 15%, the regeneration flow rate is 4m / h, and the forward and backwash flow rates are 15m / h , The positive and negative washing time is 20 minutes.

Embodiment approach 3

[0033] Ion exchange resin adopts strongly acidic cation exchange resin D001 and weakly basic anion exchange resin D370.

[0034] Strongly acidic cation exchanger: run at a water temperature of 15°C, the pH value of the influent water is 8; the exchange flow rate is 6m / h, the concentration of the nitric acid regeneration solution is 30%, the regeneration flow rate is 5m / h, and the forward and backwash flow rates are 15m / h. The time for forward and backwashing is 20 minutes;

[0035] Weakly alkaline anion exchanger: run at a water temperature of 15°C, the pH value of the influent water is 8; the exchange flow rate is 6m / h, the concentration of the ammonia water regeneration solution is 20%, the regeneration flow rate is 5m / h, and the forward and backwash flow rates are 15m / h , The positive and negative washing time is 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com