Method for co-processing municipal solid wastes

A solid waste and co-processing technology, applied in the direction of solid waste removal, etc., can solve the problems of difficult site selection, difficult landing, and wide distribution of pollution sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

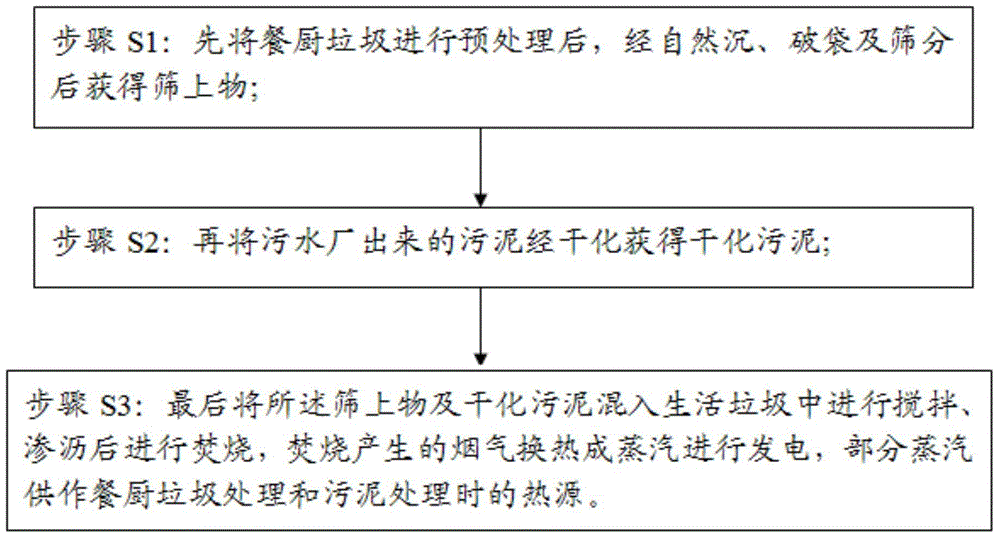

[0022] A method for co-processing municipal solid waste provided by the present invention specifically includes the following steps:

[0023] Step S1: After the food waste is pretreated, the sieve is obtained after natural sinking, bag breaking and sieving;

[0024] Step S2: drying the sludge from the sewage plant to obtain dried sludge;

[0025] Step S3: Finally, mix the sieved material and dried sludge into domestic waste for stirring and leaching, and then incinerate. The flue gas generated by incineration is converted into steam for power generation, and part of the steam is used for kitchen waste treatment and sludge treatment time heat source.

[0026] Among them, in step S1, the food waste is firstly pretreated, and then the sieves obtained after natural sinking, bag breaking and sieving include:

[0027] Step S11: After entering the factory, the food waste is pretreated, naturally settled and drained, the bag is broken with a bag breaking machine, and sieved through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com