A treating method of fluorine-containing waste water

A treatment method and wastewater technology, applied in the directions of water/sewage multi-stage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult molecular sieve production enterprises, achieve convenient operation management, improve removal Effect of fluorine efficiency and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

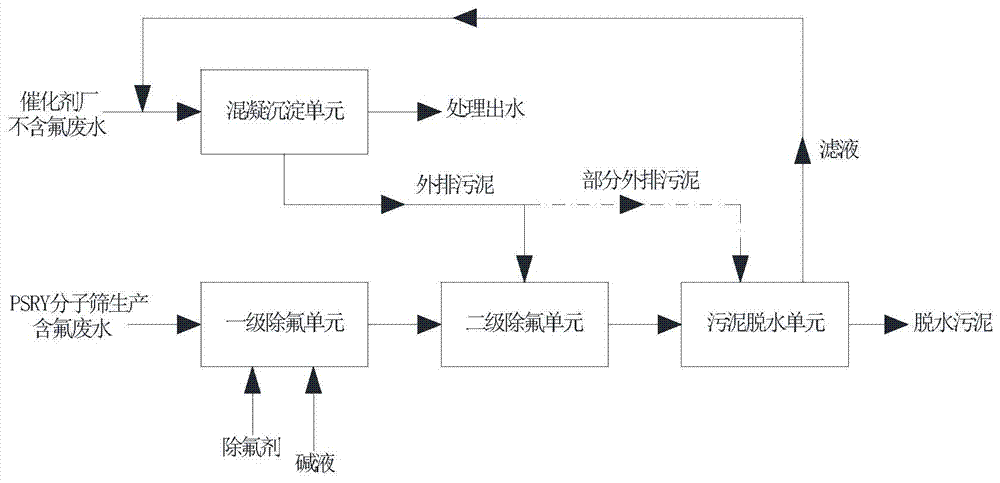

Method used

Image

Examples

Embodiment 1

[0062] This example is used to illustrate the treatment method of fluorine-containing wastewater provided by the present invention.

[0063] Production of fluorine-containing wastewater by PSRY molecular sieve: F - Content: 1441mg / L; SO 4 2- Content: 16704mg / L; Al 3+ Content: 3001mg / L; pH: 3.37.

[0064] Add 5000mg / L of aluminum chloride to 1000mL of PSRY molecular sieve production wastewater, and use NaOH aqueous solution (mass percentage concentration: 35% by weight) to adjust the pH value of the wastewater to 6.5, and stir for 20 minutes;

[0065] Then add 1000mL of the described effluent sludge to the waste water, stir and react for 20min; carry out sludge dehydration afterwards to obtain 1800mL filtrate; get the filtrate to measure F - The content is 9.1mg / L.

[0066] The filtrate is sent to the coagulation and sedimentation unit of the fluorine-free wastewater generated during the treatment of the catalyst production wastewater, mixed evenly with the coagulant (PAM ...

Embodiment 2

[0068] This example is used to illustrate the treatment method of fluorine-containing wastewater provided by the present invention.

[0069] Production of fluorine-containing wastewater by PSRY molecular sieve: F - Content: 2223mg / L; SO 4 2- Content: 24700mg / L; Al 3+ Content: 4441mg / L; pH: 2.96.

[0070] Add 2000mg / L polyaluminum chloride to 1000mL of PSRY molecular sieve production wastewater, and use NaOH aqueous solution (mass percentage concentration: 35% by weight) to adjust the pH value of the wastewater to 6.1, and stir for 15 minutes;

[0071] Add 2000mL of said effluent sludge to the waste water subsequently, stir and react for 20min; carry out sludge dehydration afterwards to obtain 2700mL filtrate; get the filtrate to measure F - The content is 6.3mg / L.

[0072] The filtrate is sent to the coagulation and sedimentation unit of the fluorine-free wastewater generated during the treatment of the catalyst production wastewater, mixed evenly with the coagulant (PAM ...

Embodiment 3

[0074] This example is used to illustrate the treatment method of fluorine-containing wastewater provided by the present invention.

[0075] Production of fluorine-containing wastewater by PSRY molecular sieve: F - Content: 2036mg / L; SO 4 2- Content: 22200mg / L; Al 3+ Content: 4075mg / L; pH: 3.28.

[0076] Add 5000 mg / L polyaluminum chloride to 1000 mL of PSRY molecular sieve production wastewater, and use NaOH aqueous solution (mass percentage concentration: 30% by weight) to adjust the pH value of the wastewater to 7.1, and stir for 30 minutes;

[0077] Then add 3000mL of said effluent sludge to the waste water, stir and react for 15min; carry out sludge dehydration afterwards to obtain 3600mL filtrate; get the filtrate to measure F - The content is 7.2mg / L.

[0078] The filtrate is sent to the coagulation and sedimentation unit of the fluorine-free wastewater generated during the treatment of the catalyst production wastewater, mixed evenly with the coagulant (PAM with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com