Patents

Literature

47results about How to "To achieve the purpose of resource recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing recyclable biological packaging material

The invention belongs to the technical field of polymer materials and relates to a method for preparing a recyclable biological packaging material. The method forms the material by using starch, plant fibers and an additive as raw materials and by granulating in a double screw extruder and die pressing. The Packaging material comprises 50 to 70 mass parts of starch, 15 to 30 mass parts of plant fibers and 5 to 20 mass parts of additive. The preparation method comprises the following steps: (1) weighing the raw material, stirring the weighed raw material in a stirrer for 3 to 5 minutes, uniformly mixing and obtaining a mixture; (2) graduating the mixture in a double screw extruder, extruding from an extruding die, and obtaining a granular material or product mother batch, wherein the rotation speed of the screw is 100 to 120r / min, the extrusion temperature is 100 to 120 DEG C and the feeding speed is 100r / min; and (3) filling the extruded granular material in a flat plate vulcanizer, and die pressing the granular material to obtain the recyclable biological packaging material, wherein the die pressing time is 15 minutes, and the die pressing temperature is 120 to 140 DEG C. The overall process is simple, the used raw materials are readily available, the equipment technology is mature, the degrading performance of the recyclable biological packaging material is high, the utilization rate of the recyclable biological packaging material is high, and the recyclable biological packaging material is environment-friendly.

Owner:QINGDAO UNIV OF SCI & TECH

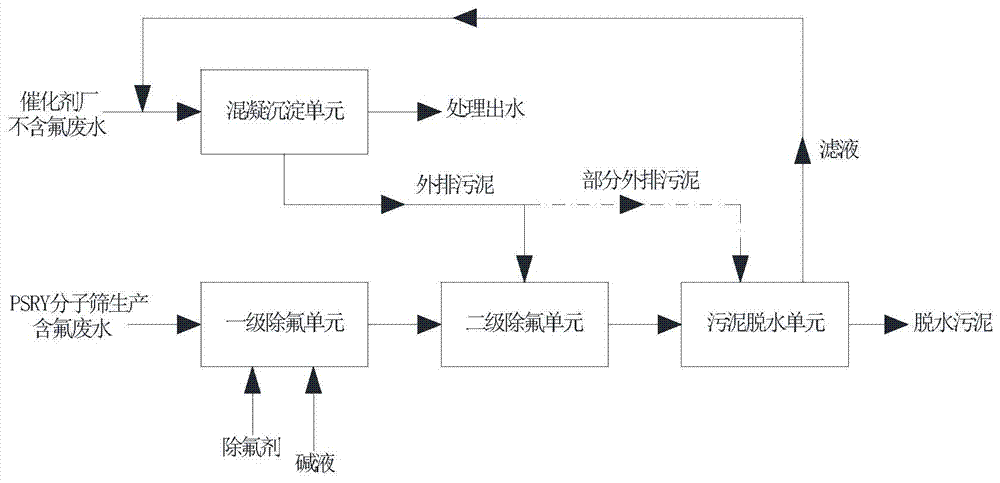

A treating method of fluorine-containing waste water

InactiveCN104512973AReduce dosageAvoid the impact of the defluoridation processWater contaminantsMultistage water/sewage treatmentWater solubleFluorine containing

A treating method of fluorine-containing waste water is disclosed. The fluorine-containing waste water comprises F-, SO4<2-> and Al<3+>. The method includes: bringing the fluorine-containing waste water and a water-soluble aluminum-source fluorine removing agent into contact and adjusting the pH value of the fluorine-containing waste water to be not lower than 5 to perform neutralization and sedimentation reactions; bringing the fluorine-containing waste water after the neutralization and sedimentation reactions and discharged sludge from a coagulating sedimentation treating unit of waste water free of fluorine into contact; and subjecting the obtained mixture to sludge dehydration to obtain dehydrated sludge and filtrate. The method can perform effective fluorine removal treatment for the fluorine-containing waste water having high contents of the F-, the SO4<2-> and the Al<3+>.

Owner:CHINA PETROLEUM & CHEM CORP +1

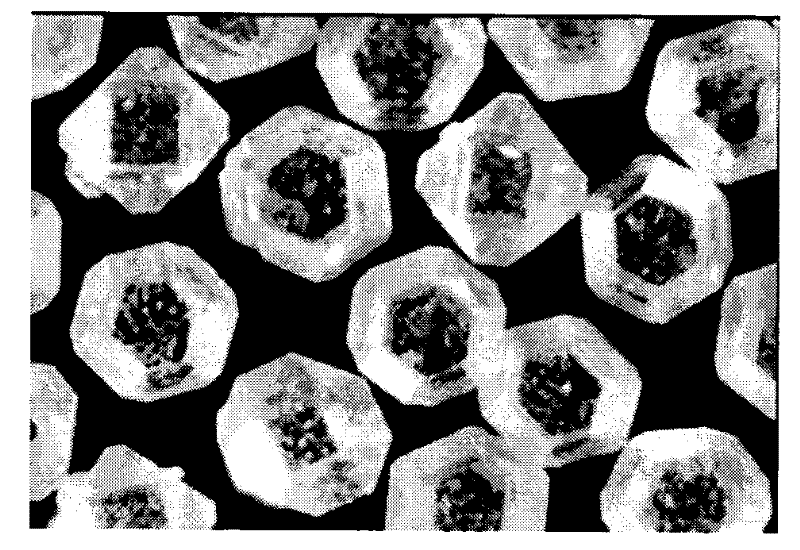

Cultivation method for edible and medicinal fungus for old fir tea trees

InactiveCN101971766AImprove the growing environmentImprove edibleHorticultureFertilizer mixturesTrace elementBran

The invention relates to a cultivation method for edible and medicinal fungus for old fir tea trees. Culture materials used in the method takes the old fir tea tree the age of which is more than 30 as a culture medium, comprising the following components by mass parts: 73-87 parts of old fir tea tree, 10-25 parts of bran, 1-5 parts of additive, and water the addition amount of which is 1.1-1.4 times the total amount of the old fir tea tree, bran and additive. In the invention, the characteristics that the old fir tea tree the tree age of which is more than 30 has excellent growing environment and more trace elements are adopted, the old fir tea tree is taken as the culture medium for culturing the edible and medicinal fungus; the method of the invention has simple cultivation materials, is easier to master, can make full use of the waste old fir tea tree again, and turns waste into value; and the cultivated edible and medicinal fungus has higher edible and medicinal value.

Owner:毛景华

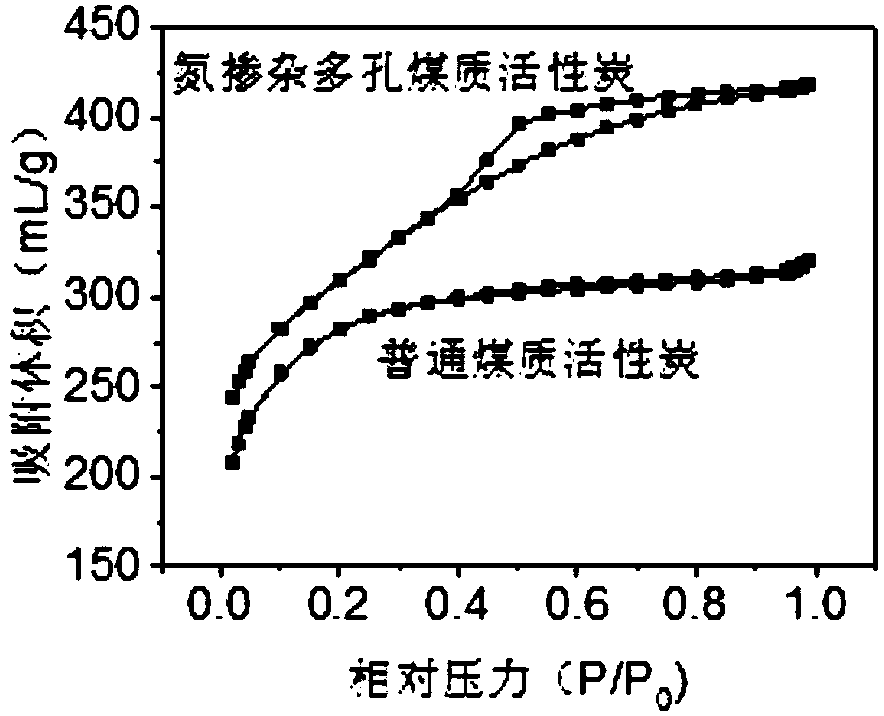

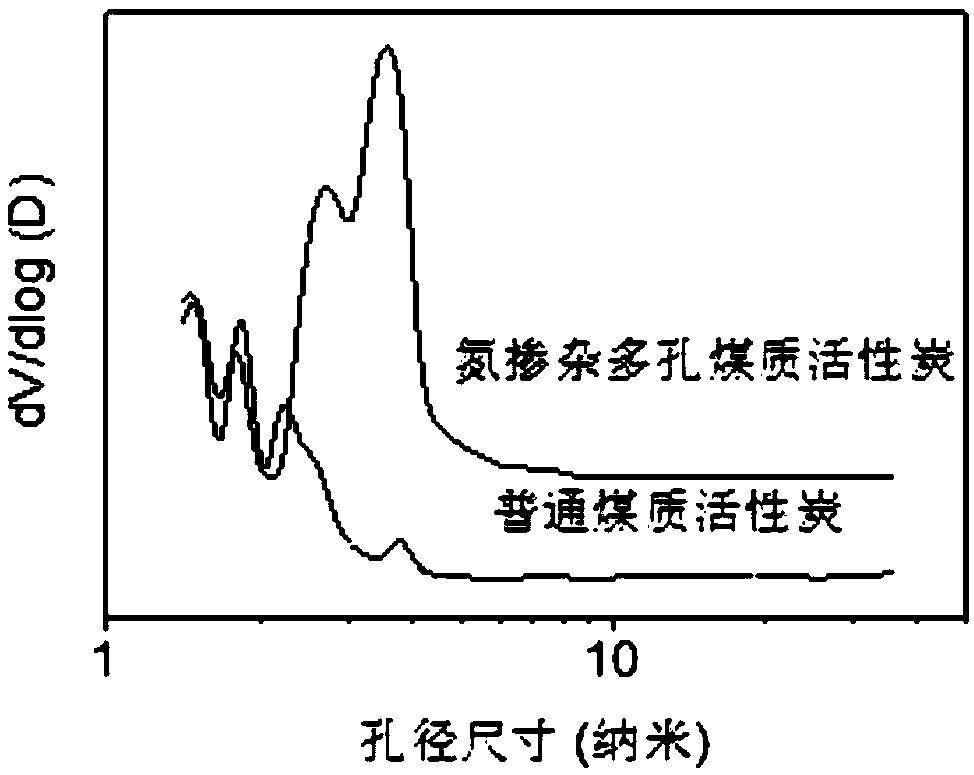

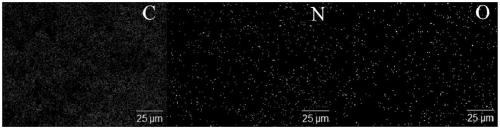

Method for preparing coal-based porous activated carbon material by using cyanamide waste residues as template

ActiveCN109319781AIncrease added valueRealize large-scale productionCarbon compoundsSorbentPorous carbon

The invention relates to the field of preparation of porous carbon materials by a rigid template method, and particularly discloses a method for preparing coal-based porous activated carbon material by using cyanamide waste residues as a template. The method comprises the following steps of crushing the crude coal, grinding into the crude coal particles with granularity of 60 to 200 meshes, addingthe cyanamide waste residues, an adhesive and water, and uniformly mixing; compressing and forming the reaction material, ventilating air, airing, and carbonizing; conveying the carbonized material into an activating furnace, leading activating gas, and activating; finally, sequentially performing pickling treatment and water washing treatment on the crude product of the activated carbon, and drying, so as to obtain the coal-based porous activated carbon material. The method has the advantages that the method is simple, and the operation is easy; the treatment cost of highly-hazardous wastes,such as cyanamide industrial waste residues, can be greatly reduced, the resources can be recycled, and the nitrogen-modified coal-based activated carbon with high added value can be obtained in onestep; the recycled carbon material can be used as an adsorbent or a catalyst carrier, so that the added value of the coal-based activated carbon is greatly increased.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of regenerated alumina-magnesia-carbon bricks for ladle edge part

InactiveCN110668831AReduce manufacturing costSolve the situation where nowhere is availableAluminium MetallicumAl powder

The invention relates to the technical field of refractory materials, and especially relates to a preparation method of regenerated alumina-magnesia-carbon bricks for a ladle edge part. The alumina-magnesia-carbon bricks comprise 55-75% of regenerated alumina-magnesia-carbon particles, 10-15% of regenerated alumina-magnesia-carbon fine powder, 5-10% of fused magnesite fine powder, 1-2% of metallicaluminum powder, 1-2% of metallic silicon powder, 3-8% of crystalline flake graphite and 2-4% of a binder. Waste magnesia carbon bricks and carbon-containing wastes left after alumina-magnesia-carbonconversion are used as main raw materials, an efficient antioxidant is added, and the regenerated alumina-magnesia-carbon bricks are generated under certain production process conditions, so that theproblem that carbon-containing wastes left after screening of waste magnesia-carbon bricks and alumina-magnesia-carbon bricks is useless is solved, the production cost of the magnesia-carbon bricks is reduced, environmental pollution and resource wastes are reduced, and the purpose of resource recycling is achieved.

Owner:SHANGHAI LIER REFRACTORY MATERIAL +1

Soil improvement fertilizer as well as preparation method and application thereof

InactiveCN109928849AIncrease crop yieldImprove soil deterioration and structural damageCultivating equipmentsFertilizer mixturesAmmonium sulfateNutrient

The invention discloses a soil improvement fertilizer as well as a preparation method and application thereof, the method comprises the following steps: uniformly mixing turf, rapeseed meal, sterilized bone meal, peptone, humic acid and potassium fulvate, and adding EM flora and bacillus subtilis to obtain a to-be-fermented material; uniformly spraying a brown sugar water solution with the mass concentration of 0. 4% into the to-be-fermented material for fermentation to obtain a fermentation product; adding amino acid, bone-prepared calcium hydrogen phosphate, monopotassium phosphate, potassium sulfate, water-soluble monoammonium phosphate, ammonium sulfate and urea into the fermentation product to obtain a mixed product; and crushing the mixed product, adding trace elements and bacillus subtilis, stirring and mixing uniformly to obtain the soil improvement fertilizer; and the soil improvement fertilizer can be used for improving and repairing soil of wolfberries and preventing and treating root rot. The improved fertilizer disclosed by the invention can meet basic requirements for nutrients in different growth stages of the wolfberries, and promotes the good development of the soil in a wolfberry planting area, the raw materials are all-water-soluble, and the preparation method is suitable for flushing and micro-drip irrigation, is convenient, saves energy and is efficient.

Owner:青海省湟中县海宁合资化肥厂

Microcrystalline glass and preparation method thereof

Microcrystalline glass is provided and is prepared by mixing raw materials which are municipal sludge ash and industrial sludge. An element ratio that is (Al+Fe):Pb:Cu:Zn in the mixture of the municipal sludge ash and the industrial sludge is equal to 2-18:1-2:1-2:1-2. A preparation method includes mixing the raw materials according to the abovementioned ratio; uniformly grinding the mixture; thenpressing the mixture into sheets with a sheet pressing machine; maintaining the temperature of the sheets in a high-temperature furnace at 850-950 DEG C for a certain period of time; and cooling to obtain the microcrystalline glass. Solid wastes are adopted as the raw materials to prepare the microcrystalline glass so that objectives of recycling resources and protecting the environment are achieved, and stabilization of three heavy metals which are Zn, Pb and Cu which are seriously harmful can be achieved at a low sintering temperature because the industrial sludge polluted by the heavy metals Pb, Cu and Zn is doped, and the doped elements destroy a regular system of a pure phase system.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Technology for recovering and utilizing mother liquor generated during process of glycine production through chloroacetic acid method

ActiveCN104310427ASolve the problem of pollution that still existsLow costAmmonium halidesGlycinePulp and paper industry

The invention relates to a technology for recovering and utilizing mother liquor generated during the process of glycine production through a chloroacetic acid method, and belongs to the technical field of glycine production. The glycine mother liquor is condensed and burned, and then the glycine mother liquid is subjected to a crystallization treatment. The burning temperature and crystallization temperature are controlled at a specific value so as to maximally reduce the ammonium chloride consumption, the recovery rate of ammonium chloride can reach 95% or more, the high quality ammonium chloride in the glycine mother liquor can be maximally recovered and reutilized, thus the environmental pollution is reduced, and the economic profit is increased at the same time. The technology also has the advantages of simple equipment and technology, and convenient operation.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

Molecular sieve synthesis mother solution using method

ActiveCN108128789ASolve the problem that cannot be recycledChanging environmental hazardsAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationMolecular sieveSuspended matter

The invention discloses a molecular sieve synthesis mother solution using method. The molecular sieve synthesis mother solution using method comprises the following steps: 1, conducting settling separation on a suspended matter of a mother solution to obtain a supernatant liquor, wherein the content of the suspended manner in the supernatant liquor is less than 0.1 g / L; 2, adding lime milk into the supernatant liquor obtained in the step 1), desiliconizing, wherein the content of SiO2 in the desiliconized supernatant liquor is less than or equal to 0.5 g / L; 3, taking the supernatant liquor desiliconized in the step 2) as a clinker in the sintering-process aluminum oxide production technique to dissolve out a regulating solution. The molecular sieve synthesis mother solution using method has the following beneficial effects: the problem that the caustic alkali in the molecular sieve synthesis mother solution cannot be recycled is solved, and the problems of the environment risks that the caustic alkali is directly neutralized by sulfuric acid and is discharged are changed. The method directly combines the production process of a molecular sieve with the production process of aluminum oxide, by removing the silicon in the solution, the molecular sieve synthesis mother solution is desiliconized to dissolve out the clinker, and the dissolved sodium metaaluminate solution is taken as a raw material in the synthesis of the molecular sieve, so that the purposes of recycling of the resources and zero emission are fulfilled.

Owner:中铝智能数维(杭州)工程设计研究院有限公司

Graphene oxide-ceramic composite powder and preparation method thereof

The invention relates to graphene oxide-ceramic composite powder and a preparation method thereof. The preparation method includes: using deionized water to wet graphene oxide, adding deionized waterto dilute, stirring for the first time, and ultrasonically treating to obtain a graphene oxide suspension; quickly adding ceramic powder into the graphene oxide suspension, and stirring for the secondtime to obtain mixed liquid of graphene oxide and the ceramic powder; performing suction filtering on the mixed liquid of graphene oxide and the ceramic powder to obtain mixed slurry, drying, and performing thermal reduction treatment to obtain the graphene oxide-ceramic composite powder, wherein the ceramic powder is made of a raw material of waste FCC catalyst. Preparation of the graphene oxide-ceramic composite powder reduces environment pollution and lowers enterprise cost, so that the objective of resource recycling is achieved. The ceramic powder and graphene oxide are mixed more uniformly and are good in dispersion performance; agglomeration of graphene oxide is avoided, and preparation cost is lowered; the preparation method is simple in process, convenient to operate, clean, efficient and suitable for large-scale production.

Owner:郴州国盛新材科技有限公司

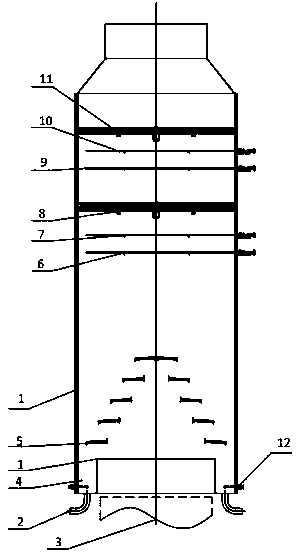

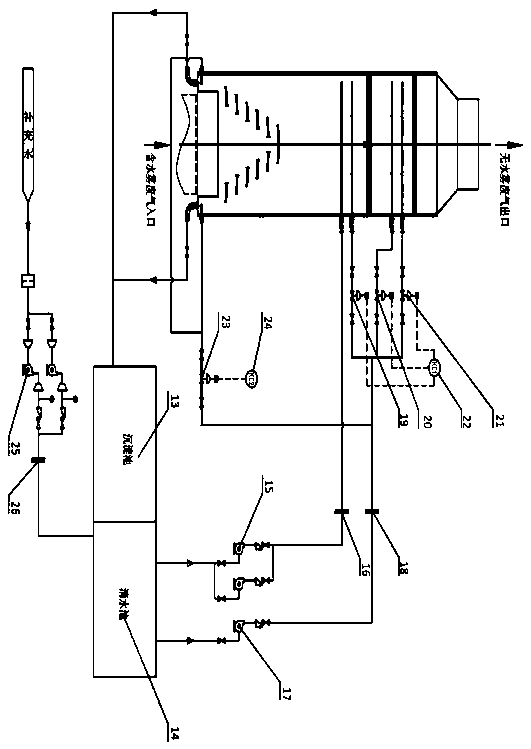

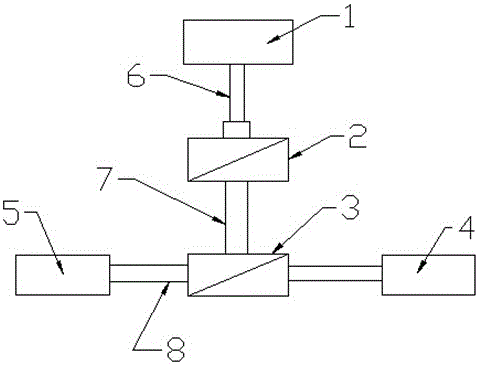

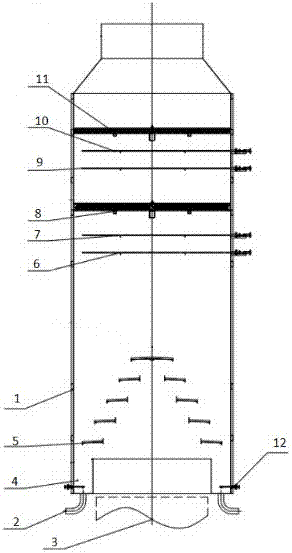

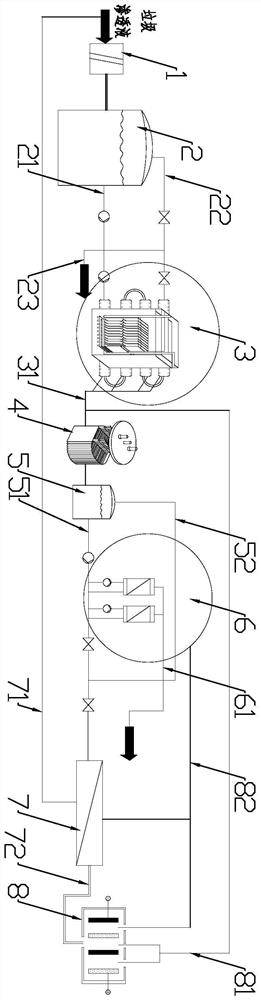

Water saving device system for efficiently eliminating mist and recycling industrial water

ActiveCN105536412APrevent backflowReasonable and smooth designCombination devicesFiltration circuitsWater savingCooling tower

The invention discloses a water saving device system for efficiently eliminating mist and recycling industrial water. The system comprises an aggregative condensing system, a two-stage inertial separation system and a condensed water recycling system, wherein the aggregative condensing system comprises spray-washing condensing devices, water receiving grid plates and a water receiving tank; the two-stage inertial separation system comprises reverse spray-washing condensing devices, a waveform inertial separator and a mesh mist eliminator; the condensed water recycling system comprises a condensed water conveying pipeline and a condensed water storage pool; the aggregative condensing system and the two-stage inertial separation system are arranged in a cooling tower; a condensed water drainage pipeline, the spray-washing condensing devices, the reverse spray-washing condensing devices and a water receiving tank washing device are connected with the condensed water storage pool through the condensed water conveying pipeline. The system disclosed by the invention has the advantages that actions of all forces among water molecules in mist can be effectively broken out, the mist is prevented from being condensed into water droplets and reflowing to a tail gas inlet pipeline, industrial water is recycled, and the purpose of recycling resources is achieved.

Owner:大连科林能源工程技术开发有限公司

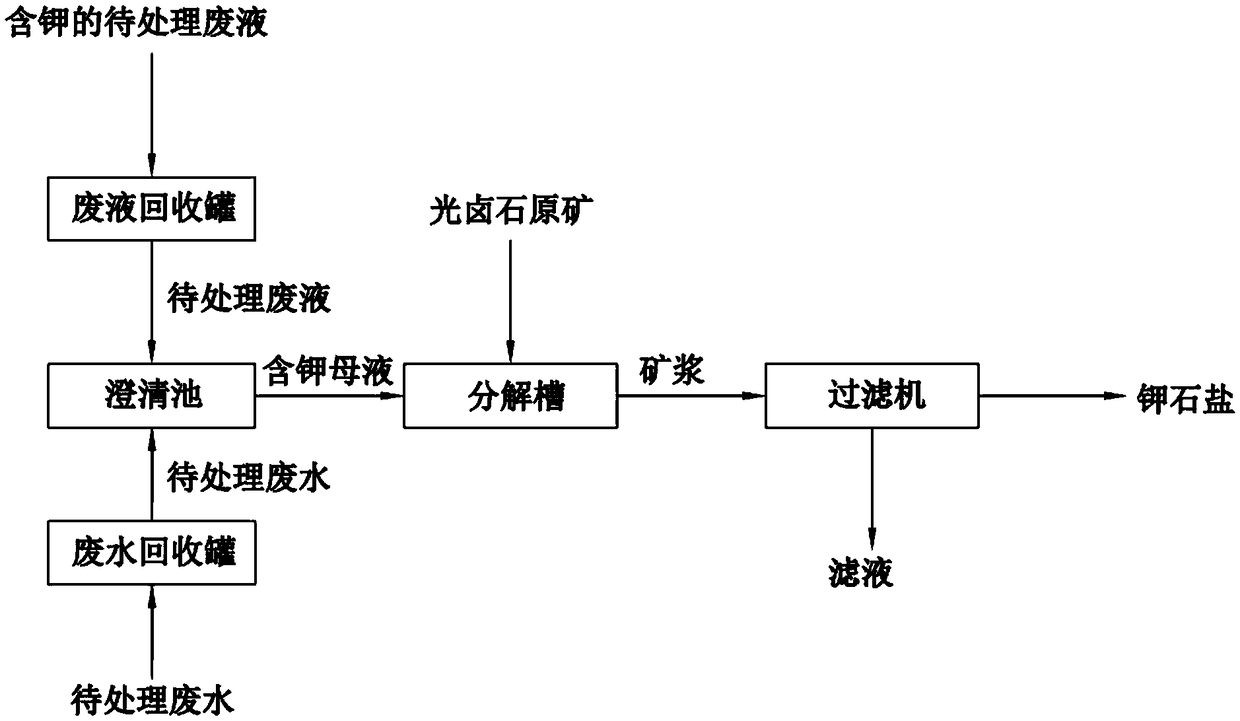

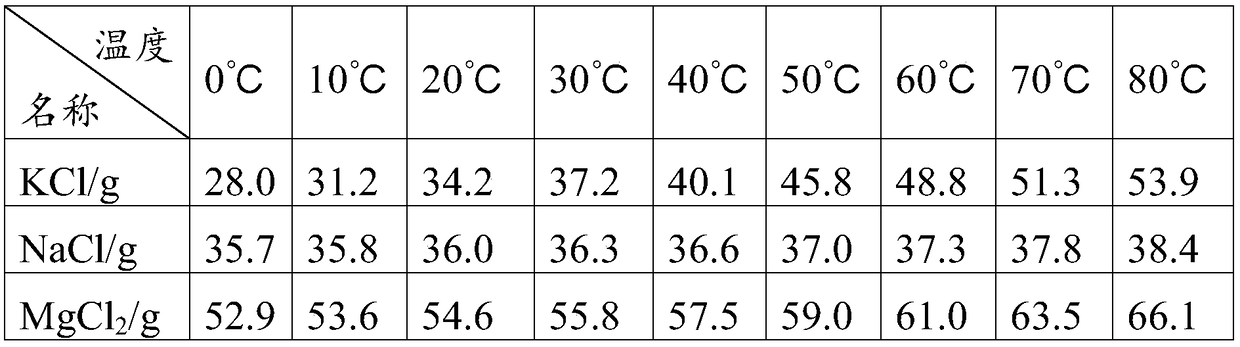

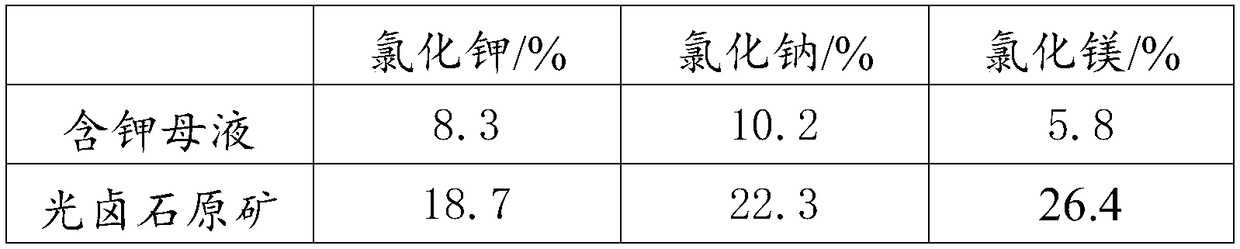

Production method of sylvinite

The invention discloses a production method of sylvinite. The production method of sylvinite comprises the following steps: proportioning potassium-containing to-be-treated waste liquor and to-be-treated wastewater to obtain a potassium-containing mother liquor; dissolving carnallite raw ores by the potassium-containing mother liquor to obtain ore pulp; and filtering the ore pulp to obtain the sylvinite. By proportioning the waste liquor and the wastewater to obtain the potassium-containing mother liquor and dissolving the carnallite raw ores by the potassium-containing mother liquor, magnesium chloride is dissolved massively and magnesium chloride is separated out in a saturated manner by means of a common ion effect, so that the sylvinite containing relatively high potassium quantity andmeeting the demands of refining potassium chloride is obtained, and water resources are saved. Influences on control 0f a follow-up production process and energy conservation and emission reduction are reduced as far as possible. Moreover, the carnallite raw ores are dissolved by the potassium-containing mother liquor, so that the baume degree of the ore pulp is increased, and the load of equipment is alleviated, therefore, the energy consumption and the loss of the equipment are further reduced to achieve the purpose of recycling resources, and the economical benefit is improved.

Owner:QINGHAI SALT LAKE IND

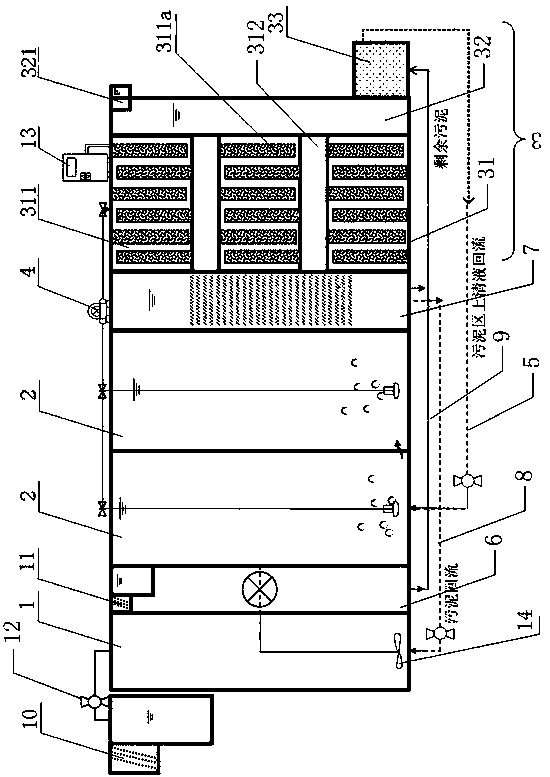

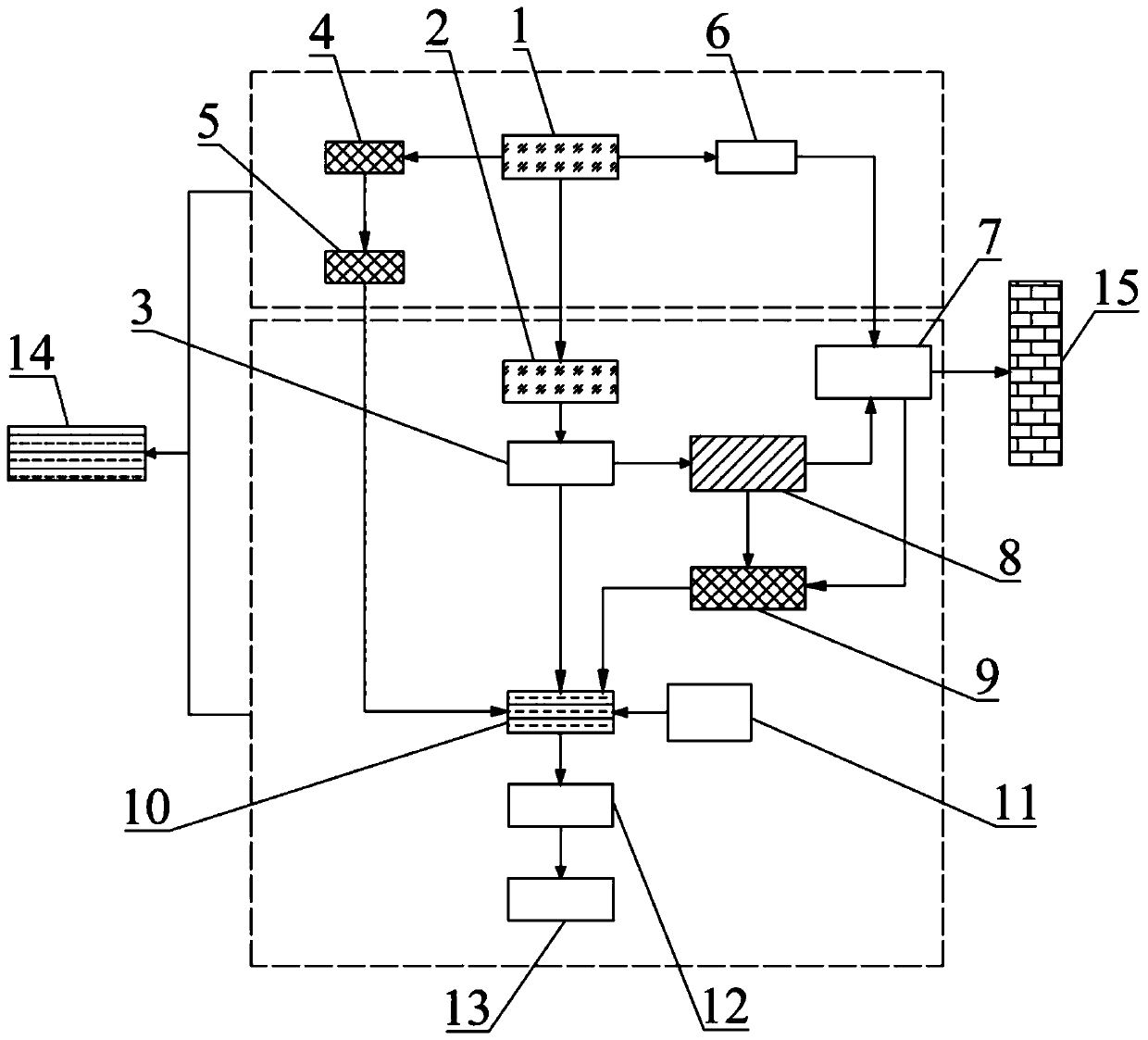

A/O combined micro electric field-Fe/C enhanced phosphorus removal device and application of phosphorus removal device

PendingCN109231673ALow running costReduce pollutionSpecific water treatment objectivesWater contaminantsAeration systemSludge

The invention discloses an A / O combined micro electric field-Fe / C process enhanced phosphorus removal device and application of the phosphorus removal device. The device comprises an anaerobic acidification tank, an intermittent aeration tank and a micro electric field-Fe / C reaction zone arranged in sequence, and further comprises an aeration system, wherein the intermittent aeration tank and themicro electric field-Fe / C reaction zone are respectively connected with the aeration system pipeline, the micro electric field-Fe / C reaction zone comprises a main reaction zone, a disinfection tank and a sludge concentration tank arranged in sequence, and the intermittent aeration tank is connected to an upper part of the sludge concentration tank through a first return pipeline; the device is stable in operation and high in efficiency, and the device can effectively remove phosphorus, nitrogen and organic matters in the sewage. The treated water quality can reach the first-class A standard ofsurface water.

Owner:GUANGDONG XINTAILONG ENVIRONMENTAL PROTECTION GRP CO LTD

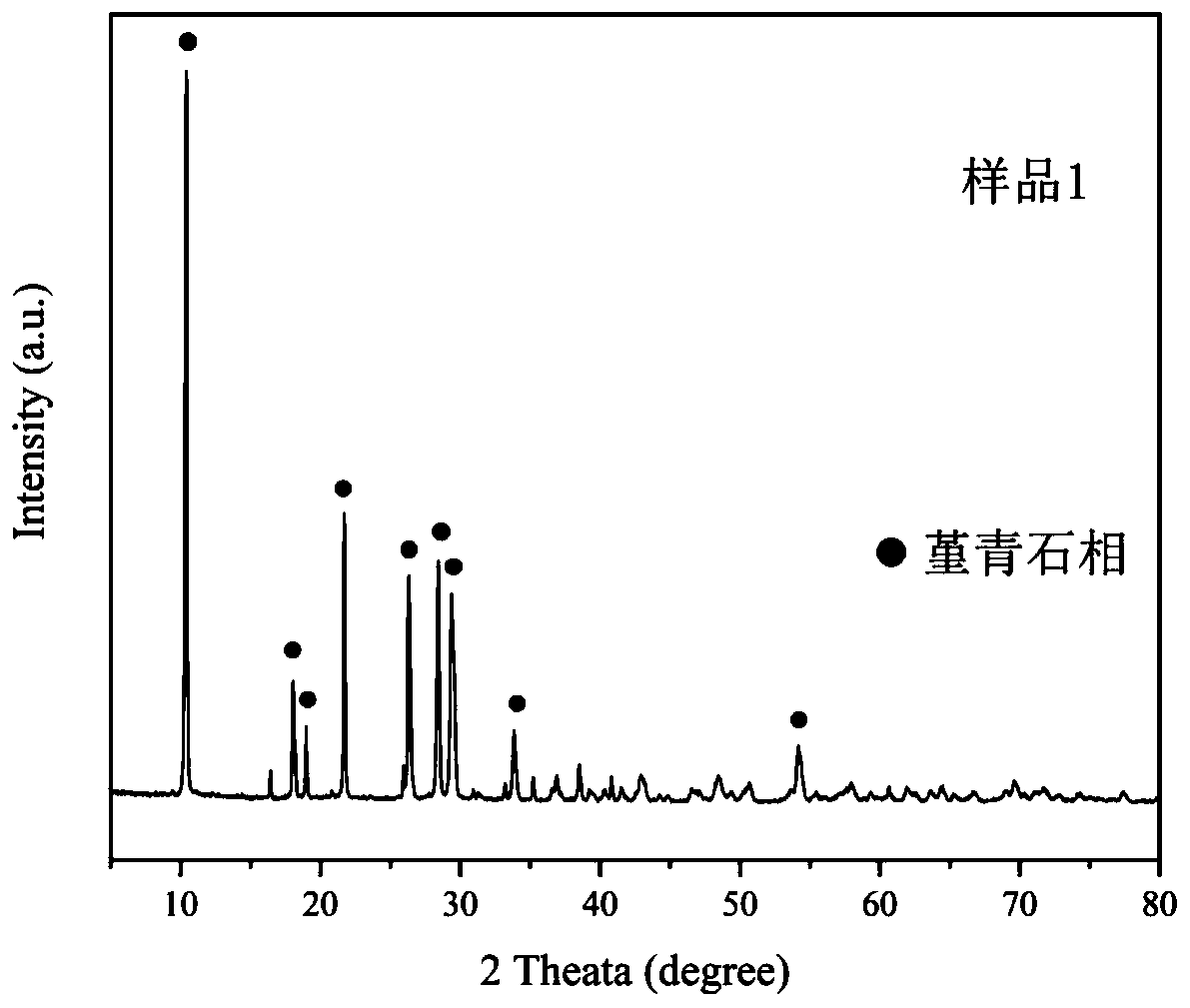

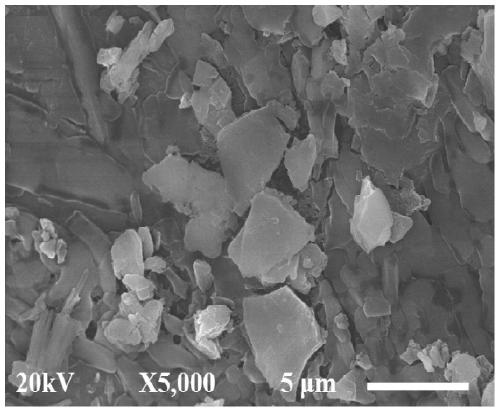

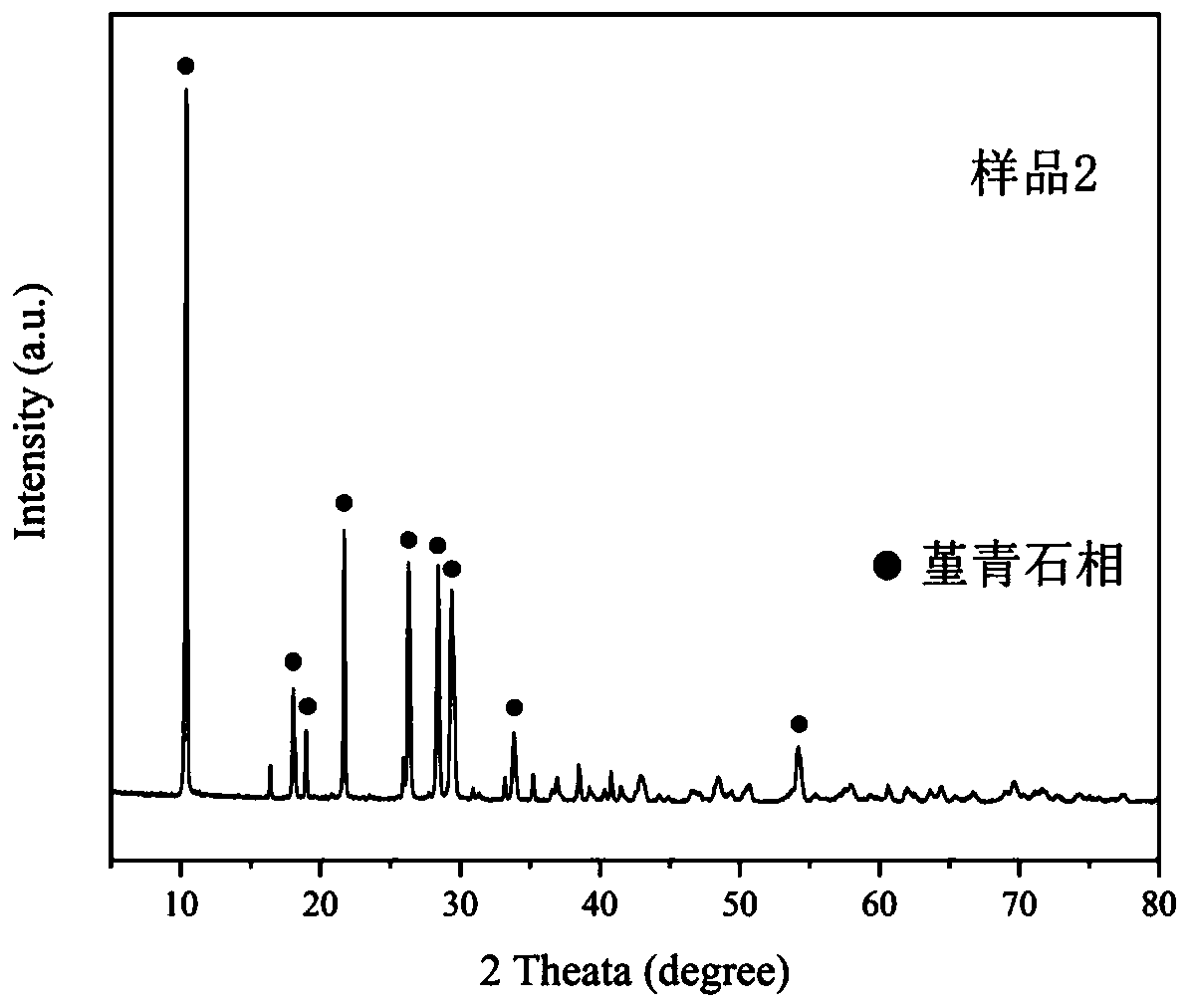

Method for preparing cordierite porous ceramic material by using waste catalyst

The invention discloses a method for preparing a cordierite porous ceramic material by using a waste catalyst. The method utilizes an industrial deactivated waste molecular sieve catalyst and a hydrotalcite catalyst as raw materials, and adopts a solid phase synthesis method to prepare the cordierite porous ceramic material with relatively high strength and high purity. The method can make the maximum use of components in the waste catalysts, the high-purity cordierite porous ceramic material can be synthesized, the pore structure of the cordierite porous ceramic material can be further enriched, the porosity is increased, the firing temperature is reduced, and the dual purposes of environmental protection and industrial waste recycling are achieved.

Owner:CENT SOUTH UNIV +1

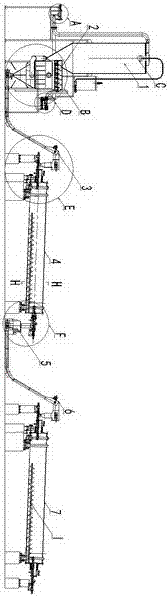

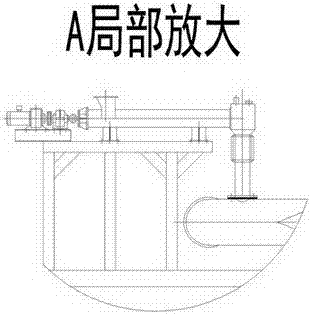

A method of using a special preparation device for activated clay

The invention relates to the technical fields of environmental protection and circular economy, and concretely relates to a use method of a special production device used for floridin. The method is characterized in that boiler tail gas used as a circulating fluidized bed coal-fired boiler fly ash conveying and activating medium and providing heat energy needed by activation and sulfuric acid used as an activator complete an activation process in an activation tower assembly, circulating fluidized bed coal-fired boiler fly ash is separated from acid fog tail gas in a gas box pulse bag type trap, an elevator I conveys the circulating fluidized bed coal-fired boiler fly ash to a rotary rinsing cylinder in order to make the fly ash be rinsed, the rinsed fly ash is dehydrated by a centrifuge dehydrator, and the dehydrated circulating fluidized bed coal-fired boiler fly ash which enters a secondary activating and drying rotary furnace through an elevator II undergoes secondary activation and drying under the action of the boiler tail gas used as the activating medium and providing heat energy. The device has the advantages of high automation degree, realization of integral intelligent enforcement of various complex process flows, and simplicity in operation and use.

Owner:徐州宇之阳市场营销策划有限公司

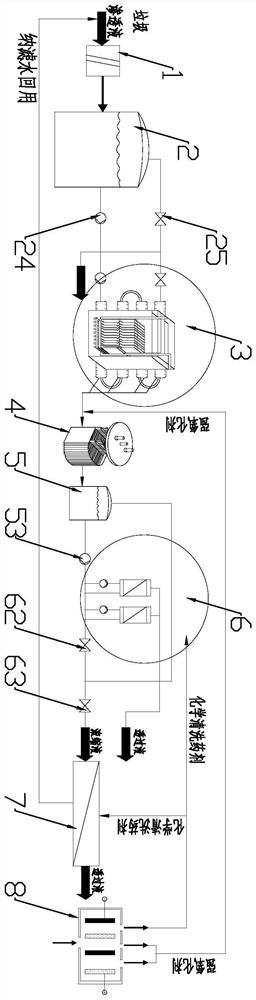

Shale gas fracturing flow-back fluid coupled membrane separating equipment and separation method

InactiveCN105036405AAchieving zero emissionsSimple structureMultistage water/sewage treatmentWater resourcesFracturing fluid

The invention provides shale gas fracturing flow-back fluid coupled membrane separating equipment and a separation method. The equipment comprises a shale gas fracturing flow-back fluid pretreatment facility, a primary ultrafilter membrane separation facility, a secondary micro-filter membrane separation facility, a waste mud and rock debris pool, and a clean water pool; the shale gas fracturing flow-back fluid pretreatment facility is communicated with the primary ultrafilter membrane separation facility through a pipeline (A); the primary ultrafilter membrane separation facility is communicated with the secondary micro-filter membrane separation facility through a pipeline (B), and the secondary micro-filter membrane separation facility is communicated with the waste mud and rock debris pool and clean water pool through a branched pipeline. The provided equipment has the advantages that the equipment structure is simple, the manufacture and application costs are low, the processed shale gas fracturing flow-back fluid can reach the standards of reuse water and can be used to produce fracturing liquid; the problem that the shale gas development needs a great amount of water is solved, the resource is fully used and recycled, and the zero discharge of shale gas fracturing flow-back fluid can be realized.

Owner:成都科特柯本科技有限公司

Method for separating and recovering crystallized phenol from phenol-containing dilute solution

ActiveCN102320682BReduce processing costsImprove separation efficiencyOrganic chemistryOrganic compound preparationSeparation technologyLow vacuum

A method for separating and recovering crystallized phenol from a phenol-containing dilute solution comprises the following steps: circulating and introducing low-concentration phenol waste water or a solution into a pervaporation device, enriching phenol steam into a low-vacuum phenol collector cooled by liquid nitrogen by using a pervaporation membrane with excellent selectivity to phenol, adding a metal wire mesh filler into the collector as a substrate for phenol crystallization. The invention can be used for treatment of waste water containing low-concentration phenol and can recover crystallized phenol; no chemical reagent is needed to be added, which eliminates secondary pollution; the invention realizes energy saving, emission reduction and resource recovery of waste water, and isenvironment-friendly high-efficient separation technology.

Owner:TAIYUAN UNIV OF TECH

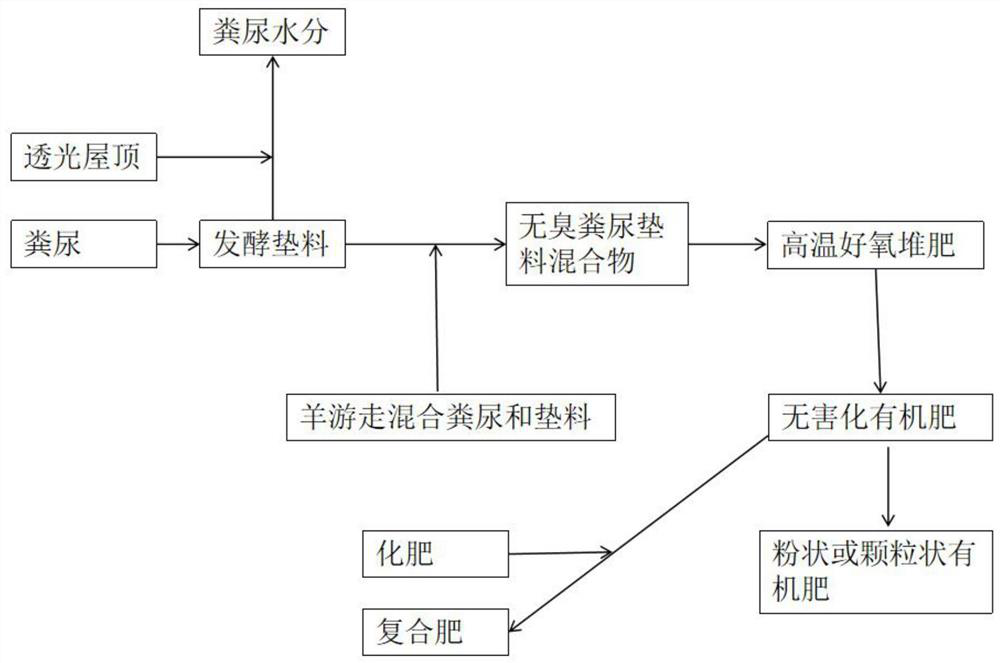

Zero-emission excrement treatment method for ecological breeding of goats

InactiveCN111995446ASolve the problems of healthy developmentZero emissionBio-organic fraction processingExcrement fertilisersEnvironmental engineeringOrganic fertilizer

The invention discloses a zero-emission excrement treatment method for ecological breeding of goats. The method comprises the steps that a goat bed is manufactured, specifically, ground flat breedingis conducted, microbial padding is laid on a microbial padding free bed; the goats naturally excrete excrement and urine on the microbial padding; the sheep house adopts a modern ecological fence house structure, and light is transmitted through the roof, so that excrement and urine moisture on the fermentation padding is evaporated; excrement and urine generated by sheep migration are mixed withthe microbial padding; the mixtures obtained in the step 3 and the step 4 are mixed to obtain an odorless excrement and urine padding mixture; high-temperature aerobic composting is conducted on the odorless excrement and urine padding mixture obtained in the step 5 to obtain a harmless organic fertilizer; and the harmless organic fertilizer in the step 6 and a chemical fertilizer are mixed and stirred to obtain a compound fertilizer, or the harmless organic fertilizer in the step 6 is directly processed into a powdery or granular organic fertilizer. According to the invention, ecological breeding zero-emission excrement treatment is realized, i.e., the sheep farm excrement is degraded by adopting a microbial fermentation bed mode, so that the purposes of no cleaning of the excrement and zero emission are achieved.

Owner:GUANGXI UNIV

A water-saving device system for efficient water mist removal and recovery of industrial water

ActiveCN105536412BBreaking van der Waals forceBreak gravityCombination devicesFiltration circuitsCooling towerCondensed water

The invention is a water-saving device system for efficiently removing mist and recovering industrial water, which includes a polycondensation system, a two-stage inertial separation system and a condensate recovery system. The polycondensation system includes a spray washing condensing device, a water receiving grid and a water receiving tank; the two-stage inertial separation system includes a reverse spray washing condensing device, a wave inertia separator, and a wire mesh demister; the condensed water recovery system includes condensed water Conveying pipeline, condensed water storage tank. The aggregated condensation system and the two-stage inertial separation system are arranged in the cooling tower, and the condensed water drainage pipe, spray washing condensing device, reverse spray washing condensing device and sink flushing device are connected to the condensed water storage tank through the condensed water delivery pipeline . The invention effectively breaks the effects of various forces between water molecules in the water mist, prevents the condensed water droplets of the water mist from flowing back into the tail gas inlet pipe, recycles industrial water, and achieves the purpose of resource recovery and utilization.

Owner:大连科林能源工程技术开发有限公司

Advanced treatment method of garbage permeate fluid

PendingCN111908718AHigh mechanical strengthExtended service lifeSpecific water treatment objectivesWater contaminantsWastewaterProcess engineering

The invention provides an advanced treatment method of garbage permeate fluid, and belongs to the technical field of multi-stage treatment of water, wastewater or sewage. To-be-treated garbage permeate fluid is sequentially subjected to external ceramic MBR membrane filtration, electrolytic flocculation precipitation, single-stage DTRO, nanofiltration and bipolar electrolytic treatment; NaOH, HClOand NaClO solutions are formed at a bipolar electrolytic cell; NaOH is fed into a nanofiltration mechanism and the single-stage DTRO through an external circulating pipe to be used as chemical cleaning agents, and the HClO and NaClO solutions are fed into an electrolytic flocculation mechanism to be used as strong oxidants. The method is applied to treatment of garbage permeate fluid or sewage with the same property, and has the advantages of being stable in degradation, low in cost, capable of recycling effective components for multiple times and the like.

Owner:ZHEJIANG TIANXINGJIAN WATER SERVICE CO LTD

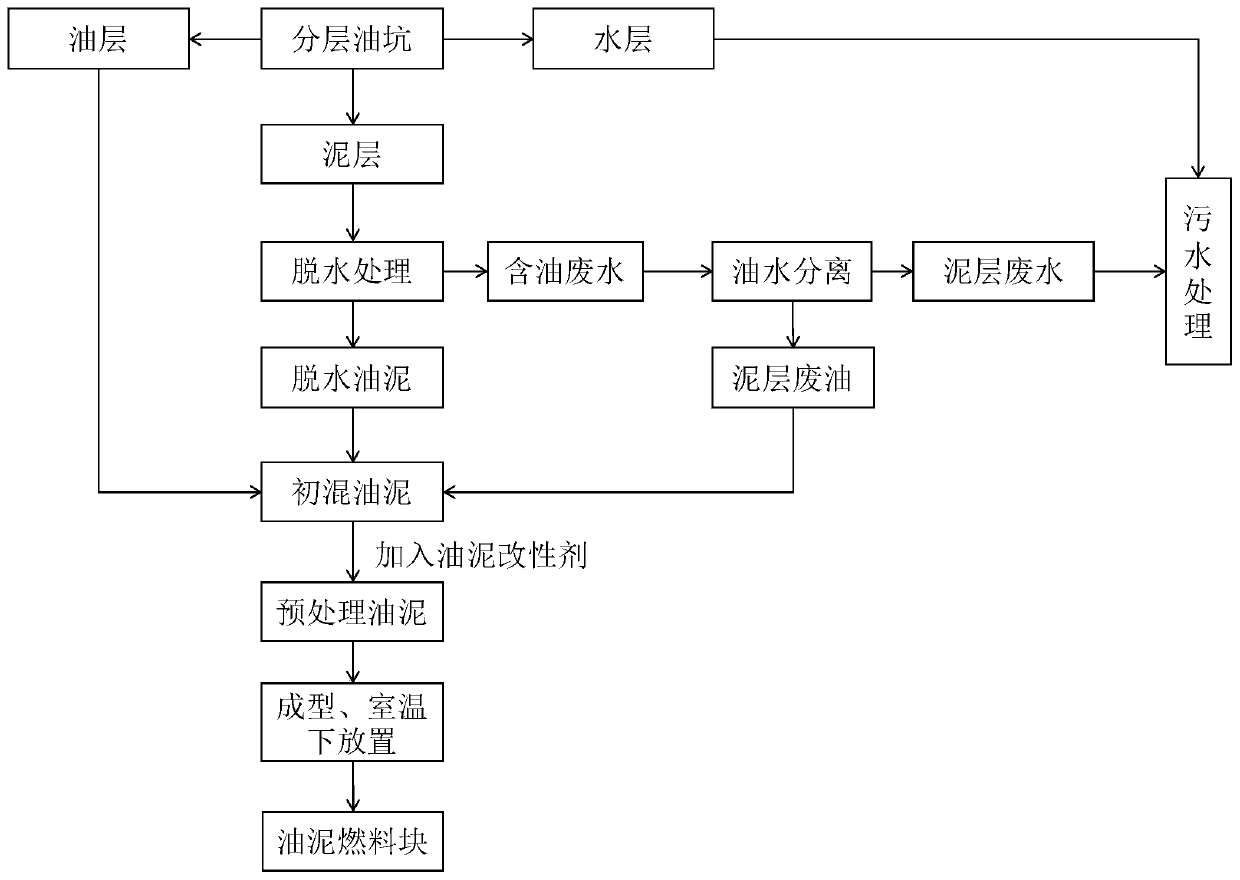

Stratified oil pit harmless treatment method and oil sludge fuel block prepared thereby

ActiveCN110255839AEfficient separationReduce pollutionSludge treatmentBiofuelsSodium BentoniteWaste oil

The invention relates to a stratified oil pit harmless treatment method and an oil sludge fuel block prepared thereby. The method includes: collecting an oil layer, a water layer and a sludge layer from a stratified oil pit; acquiring dehydrated oil sludge and oily wastewater from the sludge layer, and performing oil-water separation on the oily wastewater to obtain sludge layer waste oil and wastewater, and then carrying out sewage treatment on the water layer and sludge layer wastewater; mixing the oil layer, the dehydrated oil sludge and the sludge layer waste oil to obtain preliminary mixed oil sludge, adding an oil sludge modifier and mixing the substances evenly to obtain pretreated oil sludge, wherein the oil sludge modifier includes, by mass percentage, 50-66.5% of an auxiliary material, 13-27.5% of a curing agent, 3-10% of calcium oxide, 3-15% of bentonite and 0.3-5% of cement; molding the pretreated oil sludge, and then placing the product at room temperature, thus obtaining the oil sludge fuel block. The method provided by the invention can realize harmless, clean and recycling treatment of oil sludge in the stratified oil pit, and the content of leached heavy metals and contained dioxin and other substances in the combustion product fly ash of the prepared oil sludge fuel block is extremely low.

Owner:哈尔滨工大环能科技有限公司

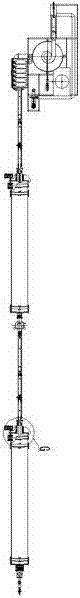

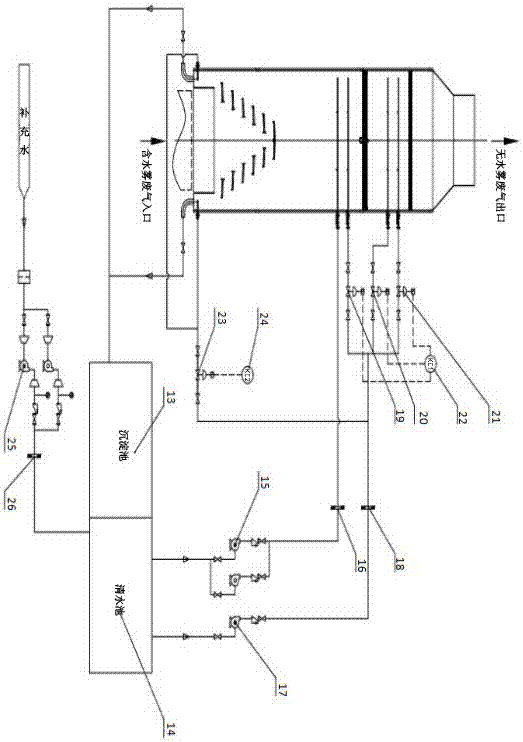

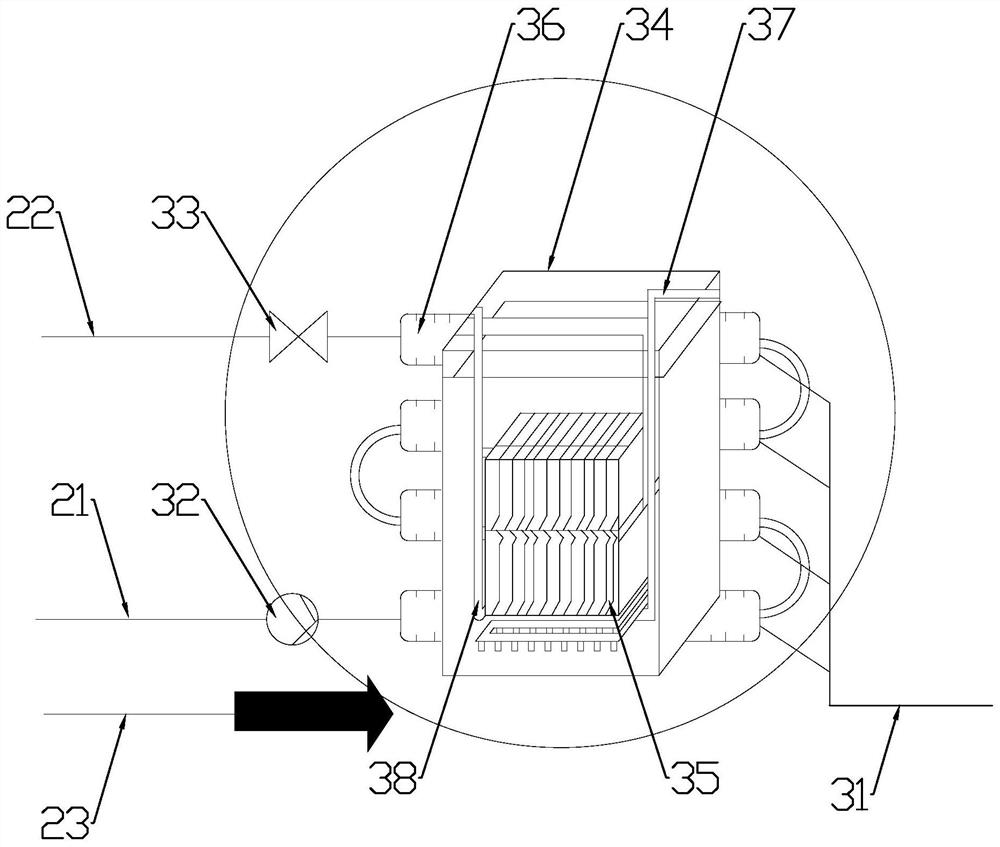

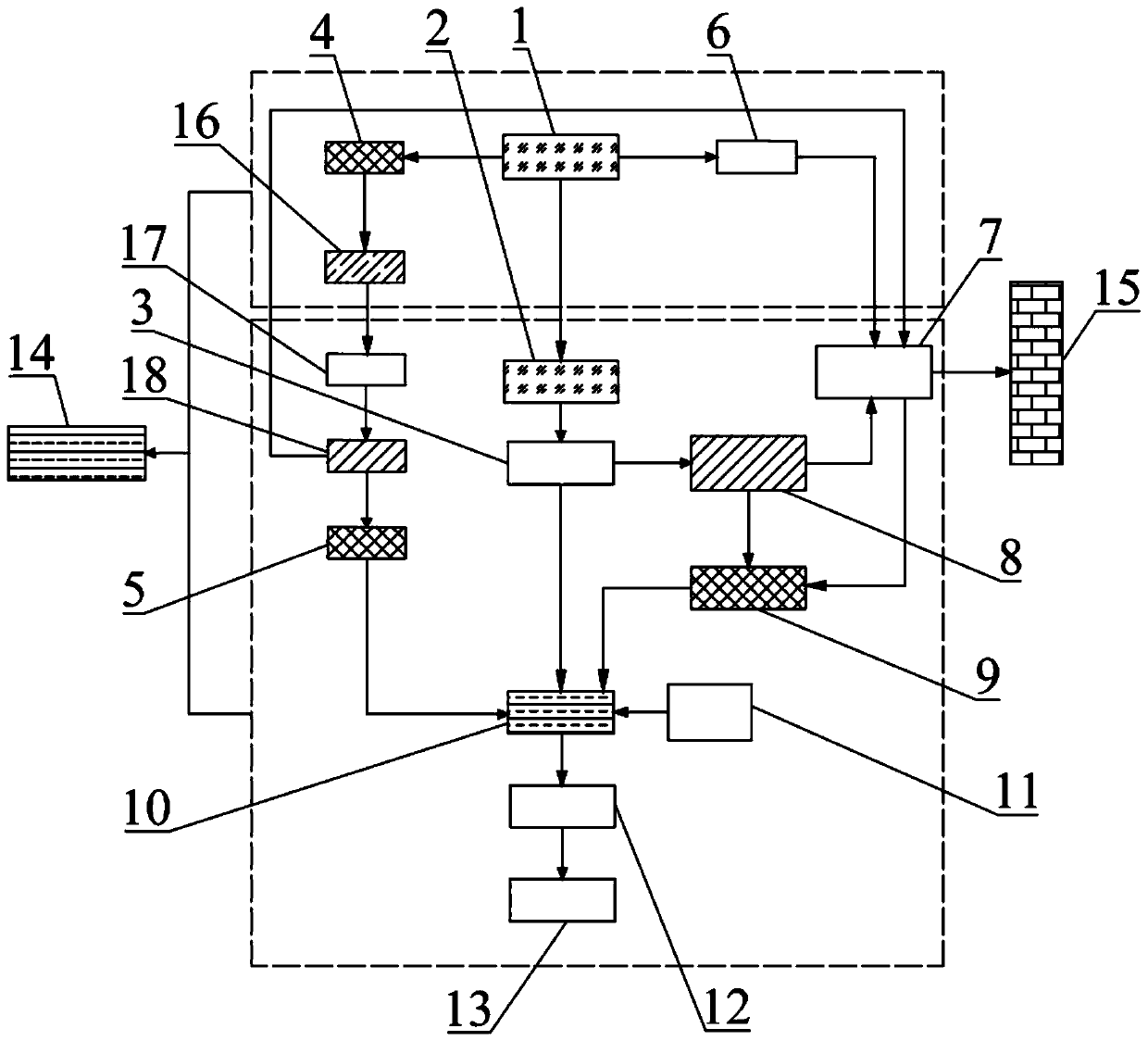

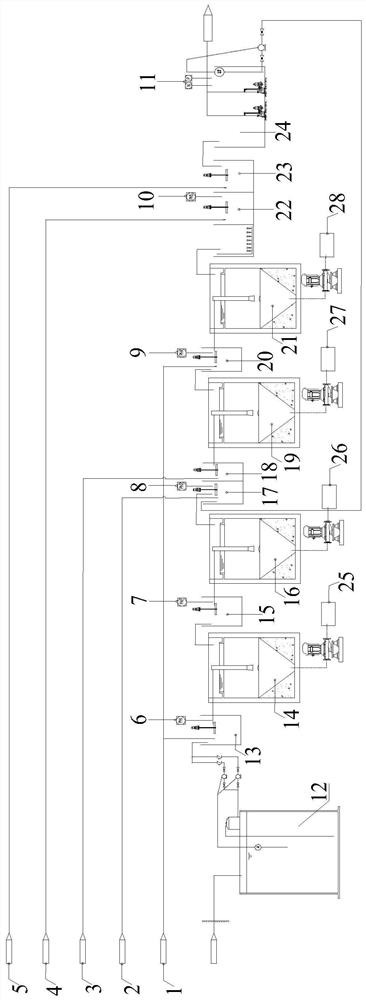

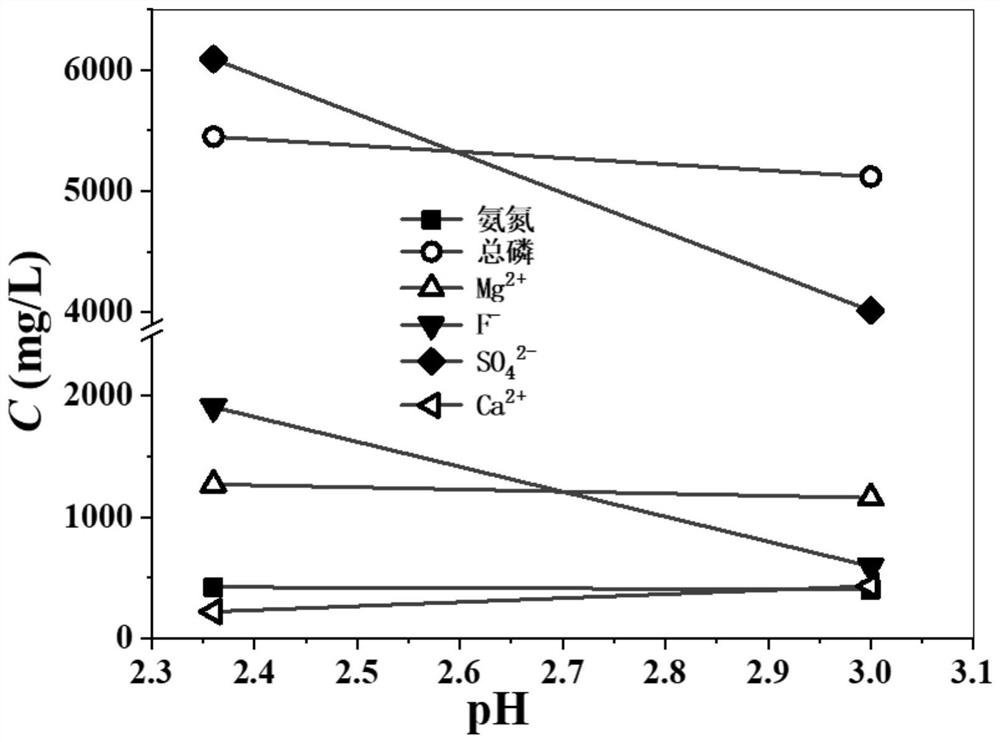

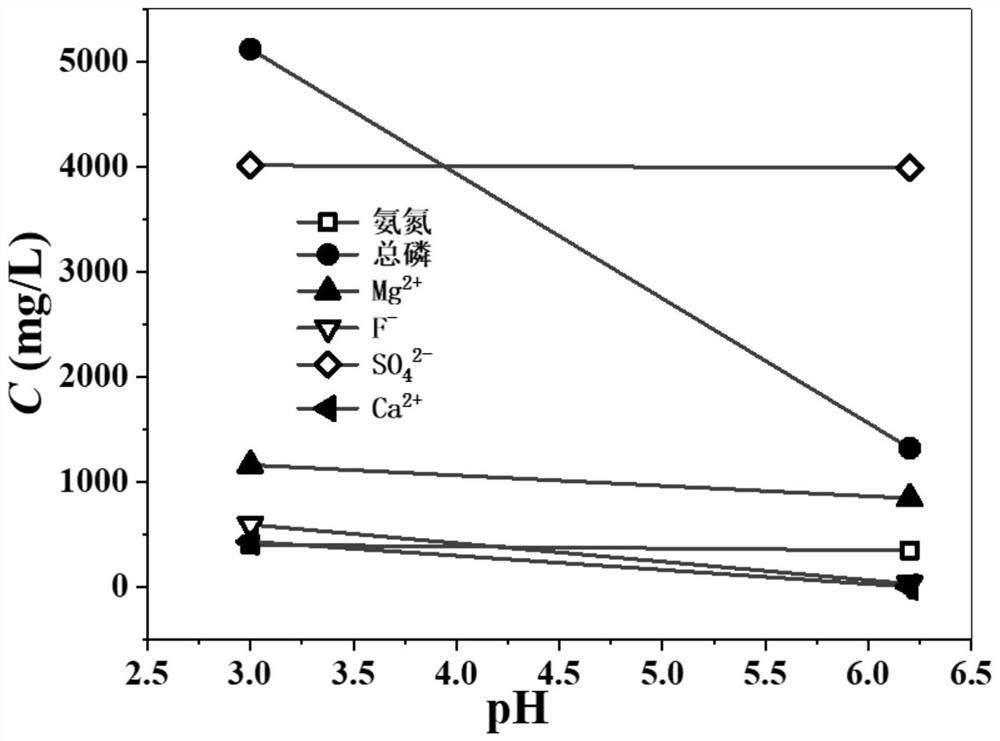

Treatment device and treatment method for recycling ardealite leachate

PendingCN113121035ATo achieve the purpose of resource recyclingEfficient recyclingWater contaminantsMultistage water/sewage treatmentEngineeringSewage treatment

The invention belongs to the technical field of industrial sewage treatment, and relates to a treatment device and a treatment method for recycling ardealite leachate. The treatment device for recycling ardealite leachate comprises a water collecting tank, a self-control dosing system, a mixing and settling system, a clean water tank and a product discharge system. A water inlet communicated with the water collecting tank is formed in the water collecting tank; the water collecting tank is communicated with the clean water tank through the mixing and settling system; the clean water tank is connected into the mixing and settling system; a water outlet communicated with the clean water tank is formed in the clean water tank; and the self-control dosing system and the product discharge system are respectively communicated with the mixing and settling system. According to the treatment device and the treatment method for recycling ardealite leachate, N, P and F elements are separately precipitated and separated out, no solid waste is generated, and the purpose of resource recycling can be achieved.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES +1

A kind of roof greening substrate and roof greening method

ActiveCN103787731BIncrease fertilizer and water retention performancePrevent escapeHorticultureFertilizer mixturesFiberPlant roots

The invention relates to a novel roof greening matrix and a roof greening method. The greening matrix comprises a core matrix and an auxiliary matrix, wherein the core matrix comprises a sludge compost product, garden waste fibers and a water retaining agent according to the weight ratio of (35-43):(55-65):(1-1.2); the auxiliary matrix comprises vermiculite and perlite; a ratio of the total weight of the core matrix to the weight of the vermiculite to the weight of the perlite is (68-82):(3-7):(15-25). The matrix provided by the invention can meet a roof greening soil utilization requirement, and sludge of a sewage treatment plant and garden waste can be effectively eliminated, and the aim of resource circulation is fulfilled; meanwhile, the greening matrix is light in material weight; raw materials are readily available; the cost is low; the fertilizer and water retaining effect is good; finally, the matrix is changed from a conventional state into a granular state, so that the problem of matrix loss can be effectively solved, and a slow release effect can be achieved; the growth of plant roots is facilitated; the specific construction and operation are facilitated; the novel roof greening matrix is suitable for the general popularization in the whole nation.

Owner:BEIJING ORIENT LANDSCAPE

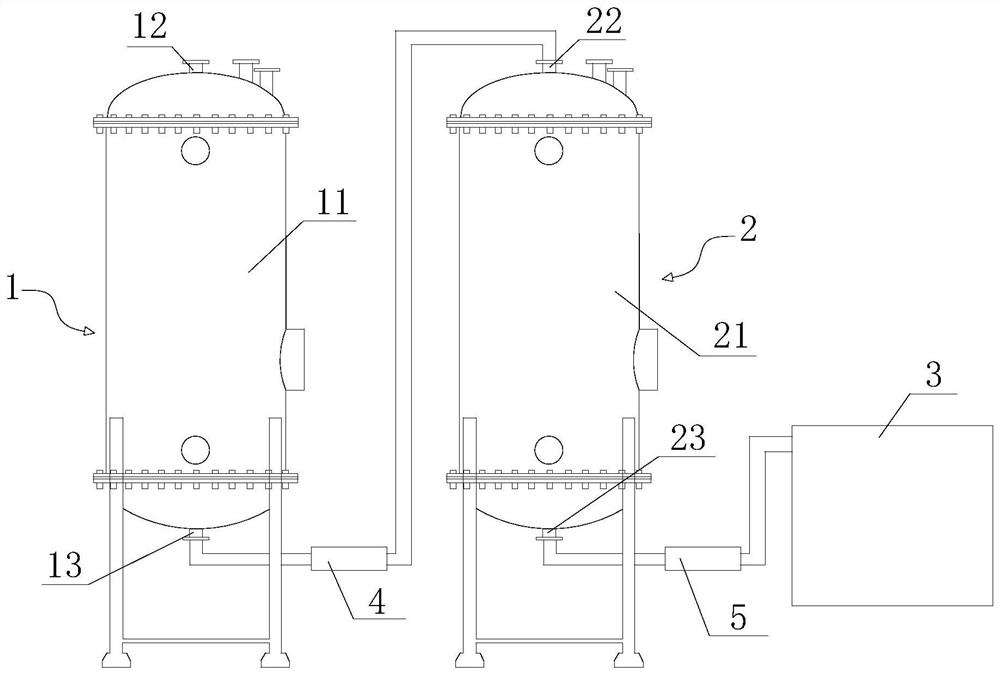

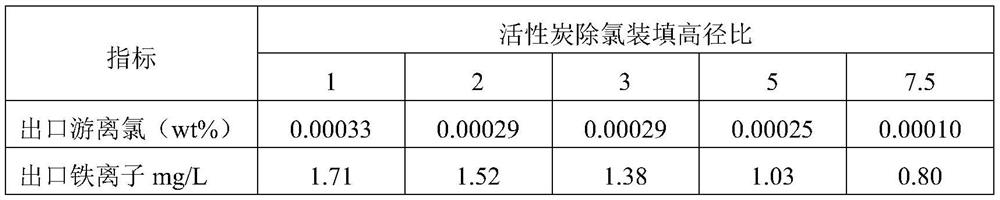

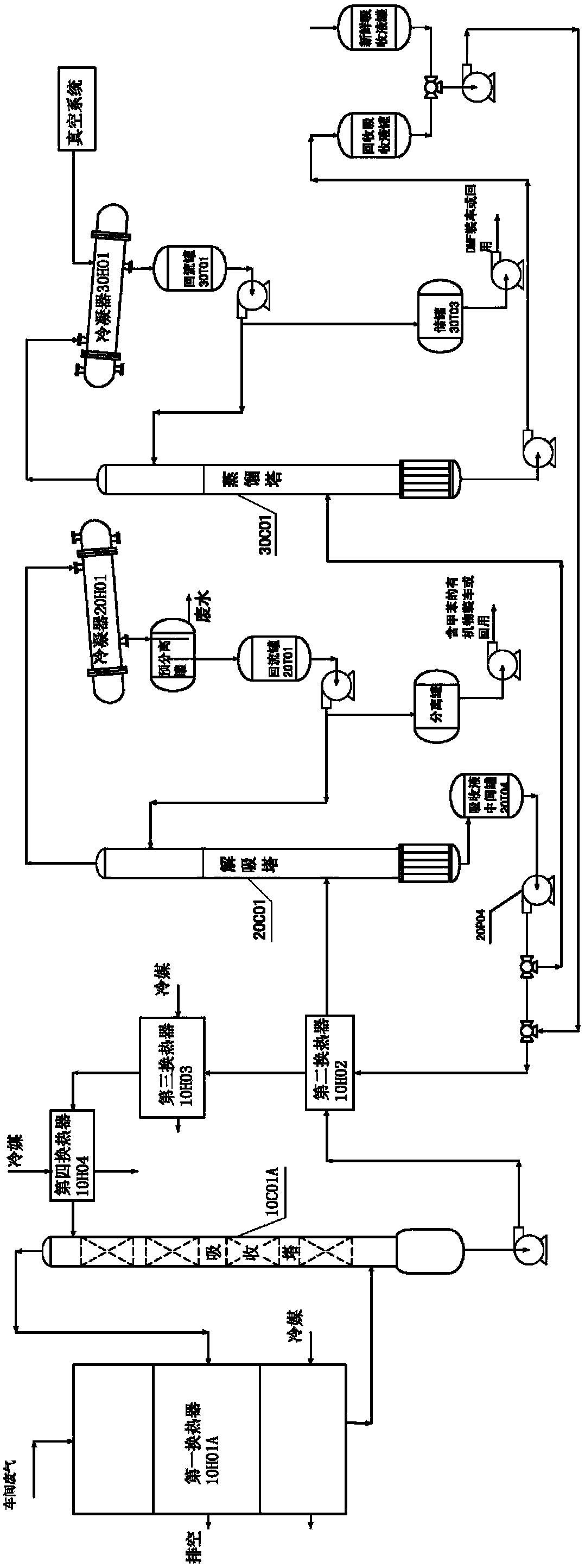

Hydrochloric acid purification system and process

PendingCN113501498AEfficient removalLow costChlorine/hydrogen-chloride purificationFiltration circuitsActivated carbonEnvironmental engineering

The invention discloses a hydrochloric acid purification system and process. The purification system comprises a dechlorination device, an iron removal device and a recovery tank which are connected in sequence. The dechlorination device comprises a dechlorination tank body, the dechlorination tank body is filled with activated carbon, a dechlorination liquid inlet and a dechlorination liquid outlet are formed in the top and the bottom of the dechlorination tank body respectively, and the dechlorination liquid inlet is used for guiding hydrochloric acid into the dechlorination tank body; the iron removal device comprises an iron removal tank body, the iron removal tank body is filled with resin, an iron removal liquid inlet and an iron removal liquid outlet are formed in the top and the bottom of the iron removal tank body respectively, the iron removal liquid inlet and the chlorine removal liquid outlet are connected through a pipeline, and a first filter is arranged on the pipeline; and the recovery tank is connected with the iron removal liquid outlet through a pipeline, and a second filter is arranged on the pipeline. The system disclosed by the invention can effectively remove free chlorine and iron under the condition that the concentration of hydrochloric acid is not obviously reduced.

Owner:CHENGDU GUOHUA ENVIRONMENTAL TECH

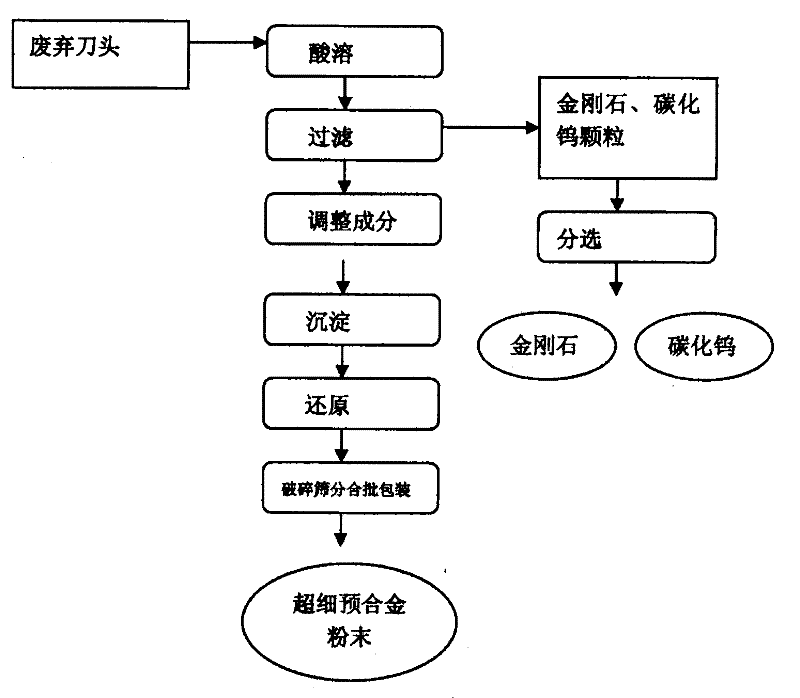

Comprehensive resource recycling method for waste diamond tool

ActiveCN101745514BGuaranteed RecoveryTo achieve the purpose of resource recyclingSolid waste disposalPregnant leach solutionCoprecipitation

The invention belongs to the fields of comprehensive resource recycle and superfine metal pre-alloyed powder preparation, and particularly relates to a comprehensive resource recycling method for a waste diamond tool. The method comprises the following steps: firstly, reclaiming diamond and tungsten carbide grains from the waste diamond tool through acid dipping and filtering processes; and detecting components of leachate by adopting atomic absorption spectrum, adjusting the components and the concentration by adding corresponding soluble salt and deionized water into the leachate, and preparing superfine pre-alloyed powder through various non-ferrous metals in the mother solution by adopting a chemical coprecipitation-reduction process. The method can furthest reclaim the diamond and tungsten carbide grains from the waste diamond tool; the prepared superfine pre-alloyed powder can be directly applied to the production of the diamond tools; and the method avoids the complex metal ionseparation processes such as extraction and impurity removal and the like adopted in the traditional metal reclamation, has the characteristics of simple process, low cost and the like, and is easy for industrialized mass production.

Owner:GRIPM ADVANCED MATERIALS CO LTD

Hand alcohol spray disinfector

InactiveCN111760183ATo achieve the purpose of resource recyclingMedical devicesMedical applicatorsAlcohol contentUltraviolet lights

The invention relates to the technical field of disinfectors, and discloses a hand alcohol spray disinfector. The hand alcohol spray disinfector comprises a disinfection box; the inner wall of the disinfection box is fixedly connected with the left side of a plate; the bottom of the plate is fixedly connected with the top of a first ultraviolet lamp; the top of the middle of the plate is fixedly connected with the bottom of a clamping block; the outer wall of the clamping block is sleeved with a rubber sleeve; the top of the rubber sleeve is fixedly connected with the bottom of the left end ofa cover plate; and the inner wall of the disinfection box is fixedly connected with the outer wall of a liquid storage box. According to the hand alcohol spray disinfector, splashed alcohol can be collected through a collecting box, the alcohol in the collecting box can be disinfected through a second ultraviolet lamp, and when the alcohol content of the collecting box is too high, a second alcohol content detector can detect the situation, so that a miniature water suction pump can convey the disinfected alcohol into the liquid storage box, and the purpose of recycling resources is achieved.

Owner:姚如囡

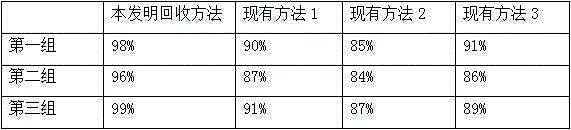

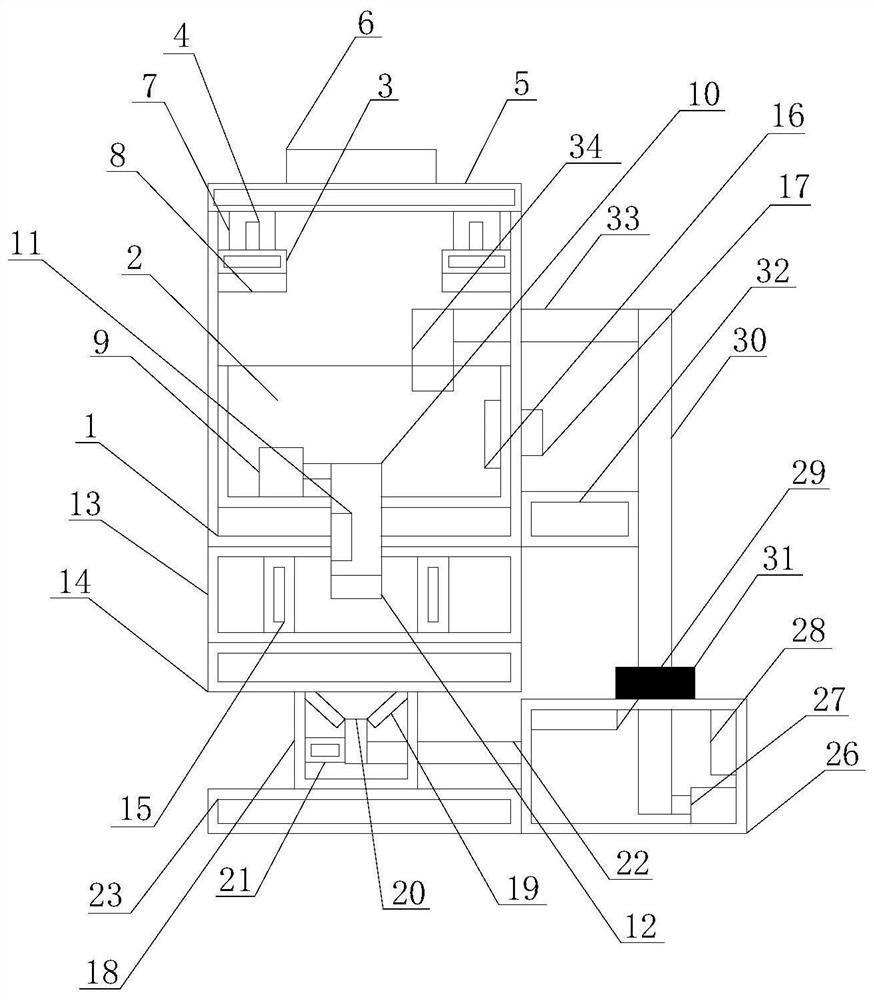

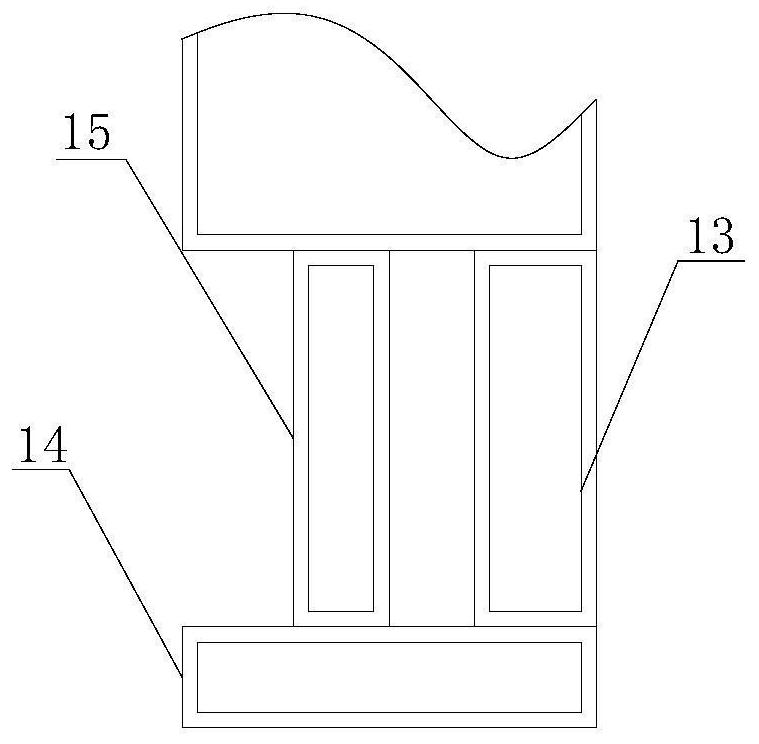

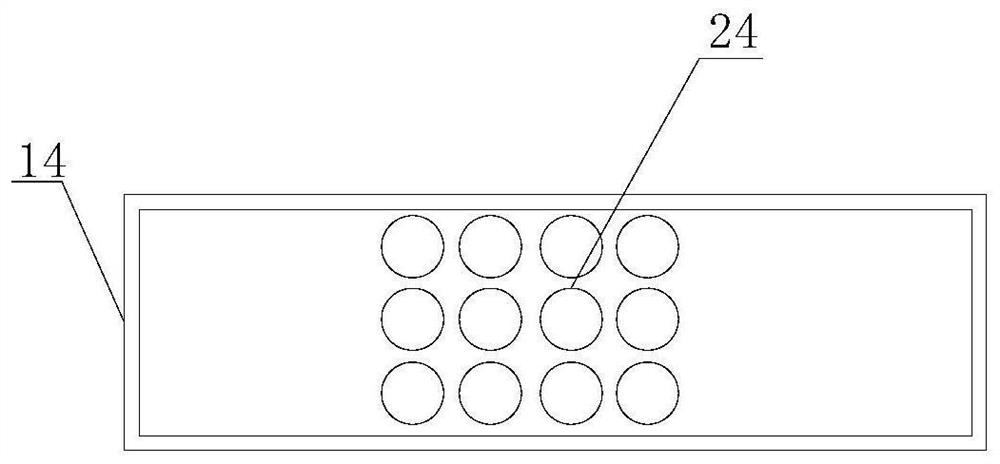

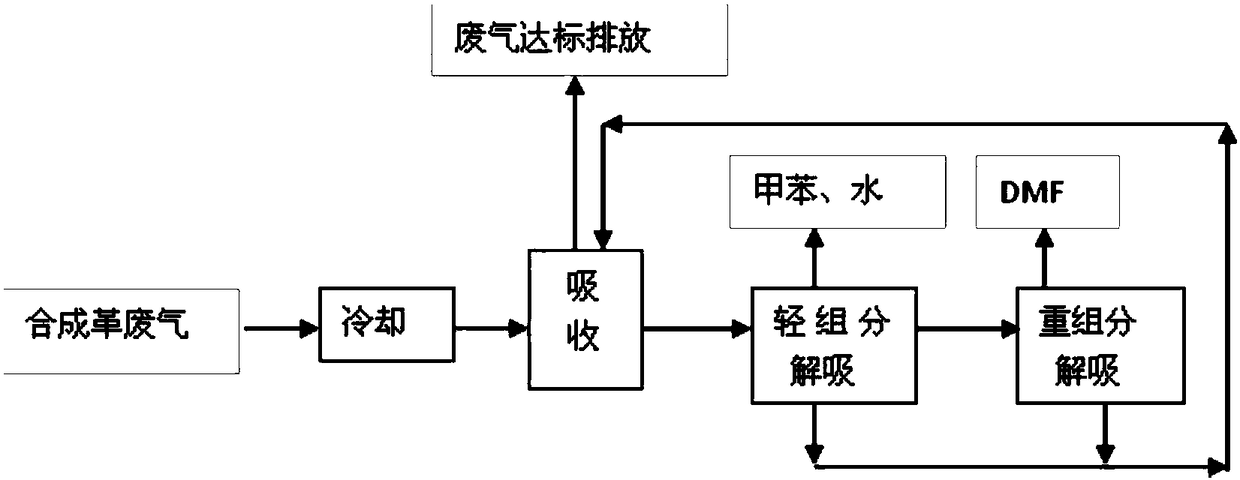

A method for recovering organic matter in waste gas of polyurethane synthetic leather

ActiveCN106187668BHigh purityEfficient recyclingOrganic compound preparationCarboxylic acid amide separation/purificationGlycol synthesisIonic liquid

The invention discloses a method of recycling organic substances from polyurethane synthetic leather waste gas. In the method, an ionic liquid and a liquid ester are employed as special absorbers. In an absorption column, cooled synthetic leather waste gas which flows countercurrent is treated in a low-temperature spray manner, wherein organic substances, such as methylbenzene, butanone and DMF, in the waste gas are absorbed by a low-temperature absorber. The absorber then is fed into a desorption column to carry out desorption and separation to recycle the methylbenzene and butanone, and then is fed into a pressure-reduced distillation column to carry out desorption and separation to recycle the DMF. The special absorber contains 50-70% of the ionic liquid, 5-25% of dibutyl terephthalate, 15-25% of butylene terephthalate and 5-15% of ethylene glycol m-phthalate. The special absorber is more than 300 DEG C in boiling point and is suitable for absorbing the methylbenzene, butanone and DMF. The method can recycle the DMF and the methylbenzene at high recycle efficiency, wherein the recycled DMF is more than 99% in purity and low-boiling-point organic substances, such as the recycled methyl and butanone, are more than 99.5% in purity.

Owner:SHANGHAI JUYOU CHEM ENG

A method for utilizing molecular sieve synthesis mother liquor

ActiveCN108128789BSolve the problem that cannot be recycledChanging environmental hazardsAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationMolecular sieveSodium aluminate

The invention discloses a molecular sieve synthesis mother solution using method. The molecular sieve synthesis mother solution using method comprises the following steps: 1, conducting settling separation on a suspended matter of a mother solution to obtain a supernatant liquor, wherein the content of the suspended manner in the supernatant liquor is less than 0.1 g / L; 2, adding lime milk into the supernatant liquor obtained in the step 1), desiliconizing, wherein the content of SiO2 in the desiliconized supernatant liquor is less than or equal to 0.5 g / L; 3, taking the supernatant liquor desiliconized in the step 2) as a clinker in the sintering-process aluminum oxide production technique to dissolve out a regulating solution. The molecular sieve synthesis mother solution using method has the following beneficial effects: the problem that the caustic alkali in the molecular sieve synthesis mother solution cannot be recycled is solved, and the problems of the environment risks that the caustic alkali is directly neutralized by sulfuric acid and is discharged are changed. The method directly combines the production process of a molecular sieve with the production process of aluminum oxide, by removing the silicon in the solution, the molecular sieve synthesis mother solution is desiliconized to dissolve out the clinker, and the dissolved sodium metaaluminate solution is taken as a raw material in the synthesis of the molecular sieve, so that the purposes of recycling of the resources and zero emission are fulfilled.

Owner:中铝智能数维(杭州)工程设计研究院有限公司

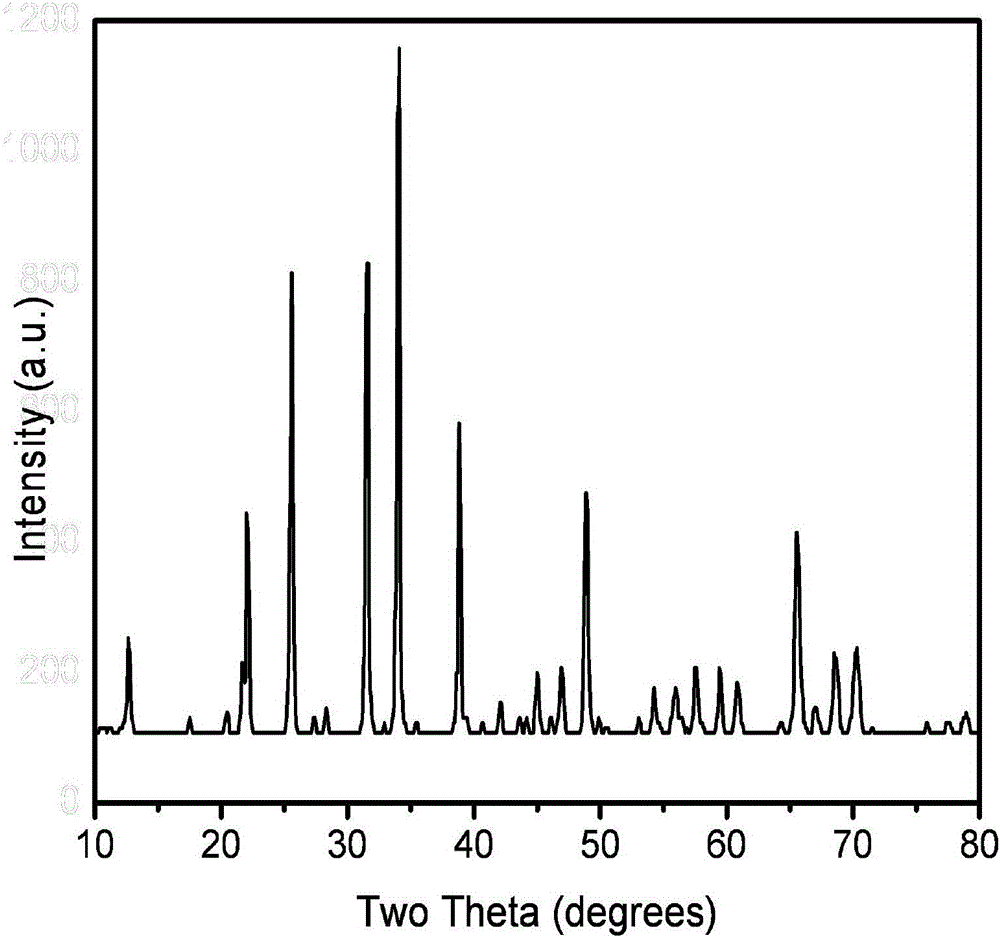

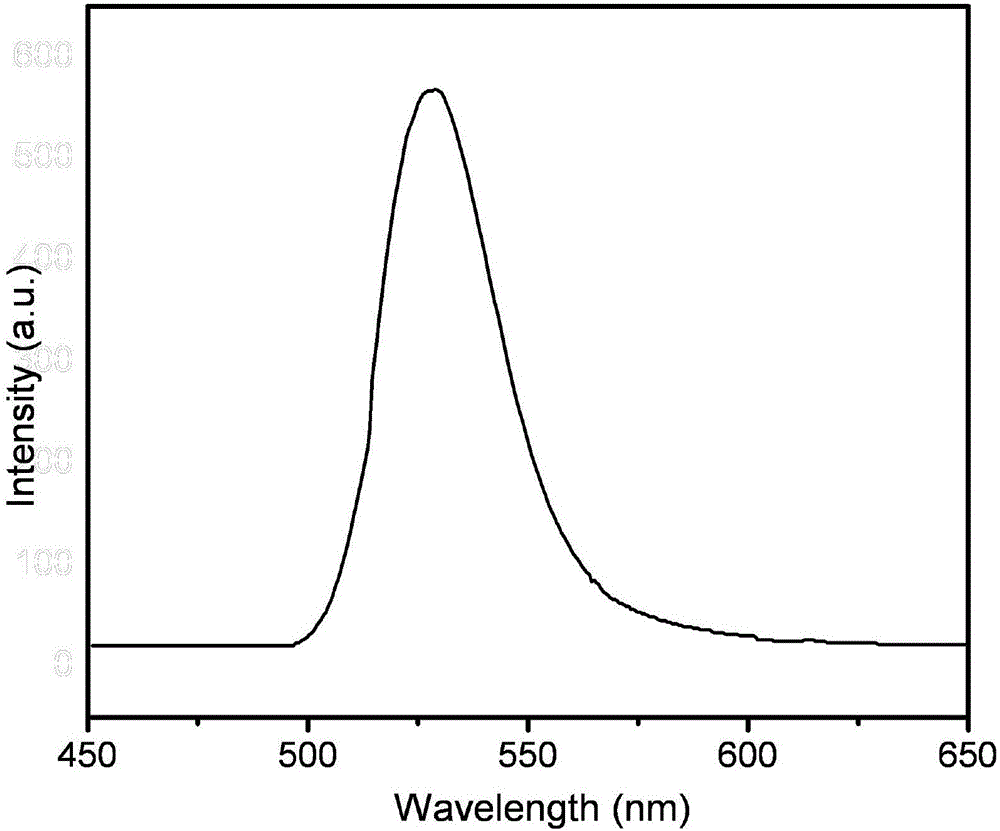

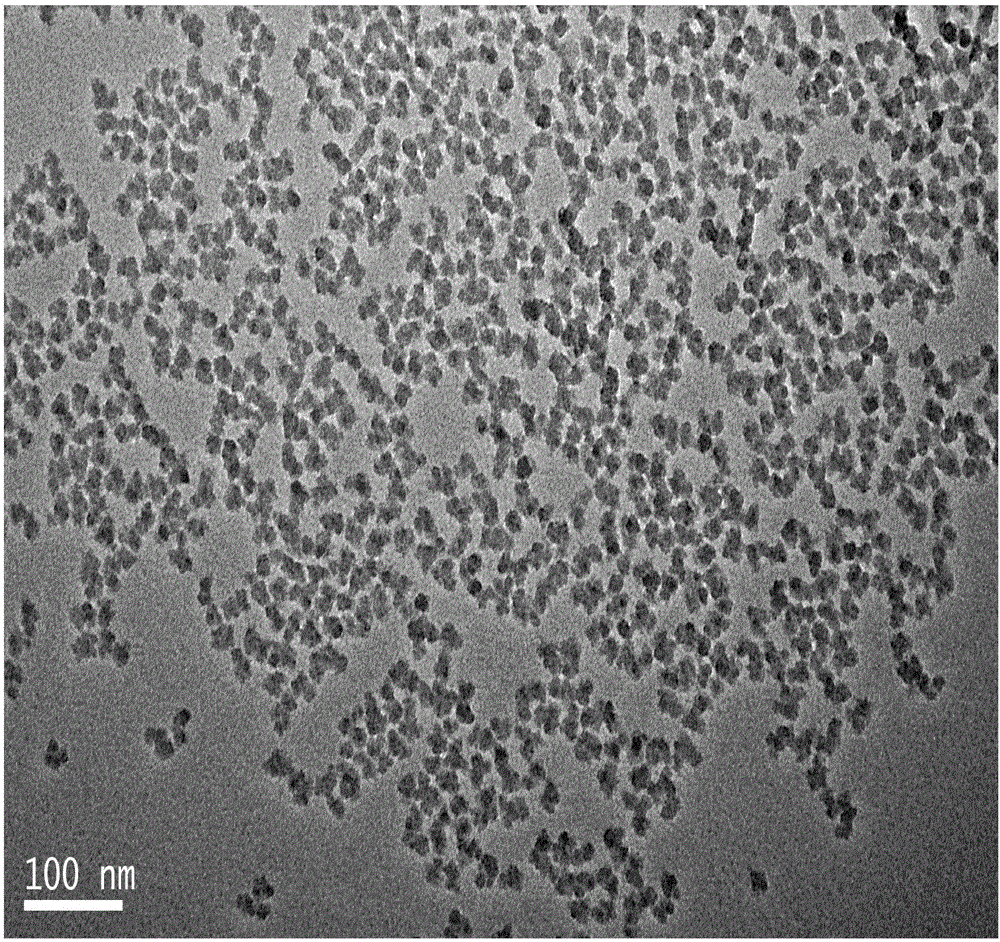

A method for synthesizing nano-zinc silicate luminescent material by using waste silicon powder hydrothermal method

InactiveCN104087289BTo achieve the purpose of resource recyclingSimple methodLuminescent compositionsMaterials sciencePolytetrafluoroethylene

The invention discloses a method of synthesizing a nano zinc silicate light emitting material by using waste silicon powder by a hydrothermal method. The method comprises the following steps: (1) dissolving Zn(CH3COO)2.2H2O, Mn(NO3)2.4H2O and hexadecyl trimethyl ammonium bromide in deionized water, adding the waste silicon powder, stirring for 15 minutes, adding sodium hydroxide or ammonium water with concentration being 25%, and stirring for 10 minutes to obtain a mixed solution; (2) putting the mixed solution prepared in the step (1) in a reaction kettle with the liner being polytetrafluoroethylene, sealing the reaction kettle, putting the kettle in an oven at 130-200 DEG C to react for 12-48 hours, taking, naturally cooling to room temperature, washing the product by distilled water. carrying out centrifugal separation, and naturally drying to obtain the zinc silicate light emitting material. By using waste silicon powder as a raw material, the method disclosed by the invention expands the range of reactants and can fully utilize industrial leftovers and achieve the purpose of recycling resources. Furthermore, the method disclosed by the invention which is a hydrothermal one-step reaction is simple and feasible and low in energy consumption.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A kind of oil sludge modifier and its preparation method and application

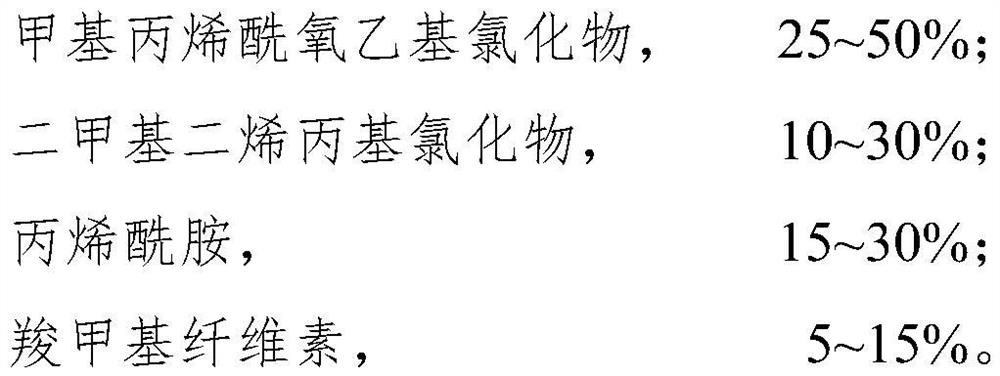

ActiveCN110257126BLarge specific surface areaImprove structural strengthSolid fuelsFuel additivesCelluloseMeth-

The invention relates to an oil sludge modifier and its preparation method and application. The oil sludge modifier contains the following components in mass percentage: auxiliary materials, 50-66.5%; curing agent, 13-27.5%; calcium oxide, 3-10%; bentonite, 3-15%; cement, 0.3-5%; auxiliary materials It is agricultural and forestry organic waste and / or industrial solid waste. The method is as follows: uniformly mix methacryloyloxyethyl chloride, dimethyl diallyl chloride, acrylamide and carboxymethyl cellulose to obtain a curing agent; add auxiliary materials, calcium oxide , bentonite and cement and mix uniformly to obtain a sludge modifier. The oil sludge modifier in the present invention can fully realize the harmless, clean and resourceful treatment of the oil sludge in the oily sludge in the oil sludge modification treatment, and the fly ash produced after the oil sludge fuel block is burned is leached. The contents of heavy metals and dioxins are extremely low, and can be discharged directly without secondary treatment.

Owner:哈尔滨工大环能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com