A method of using a special preparation device for activated clay

A technology for preparing equipment and activated clay, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., to achieve the effects of reducing activation time, production costs, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

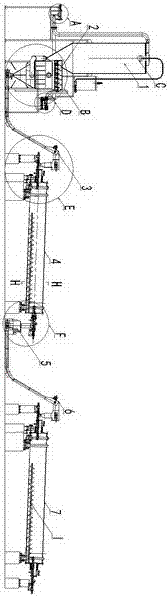

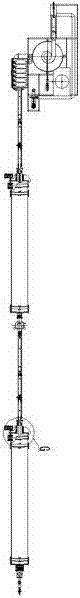

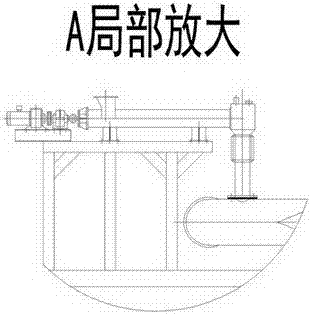

[0023] The device will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] The invention is attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , attached Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown, a method for using a special preparation device for activated clay is characterized in that: step 1, using boiler tail gas as the transport of circulating fluidized bed coal-fired boiler fly ash, activation medium and heat energy required for activation and sulfuric acid as an activator The activation process is completed in the activation tower component 1. The boiler tail gas is the boiler flue gas taken from the flue connecting the boiler heat exchange system and the dry dust collector. The temperature is about 160-190 ° C, SO 2 The concentration is about 1000-2500mg / m 3 , the fly ash of the circulating fluidized bed coal-fired boiler enters the activation tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com