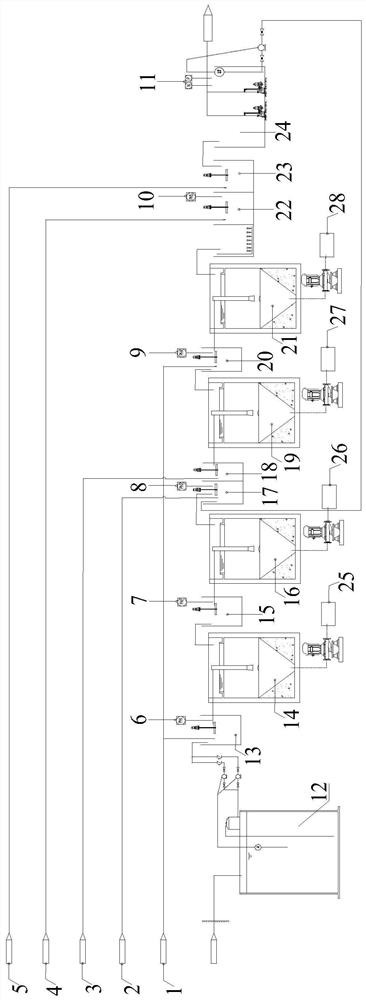

Treatment device and treatment method for recycling ardealite leachate

A treatment device and a technology for leachate, applied in the field of treatment devices for recycling phosphogypsum leachate, can solve the problems of low ammonia nitrogen removal rate, high cost, limitation, etc., and achieve the effect of simple device structure and convenient later enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

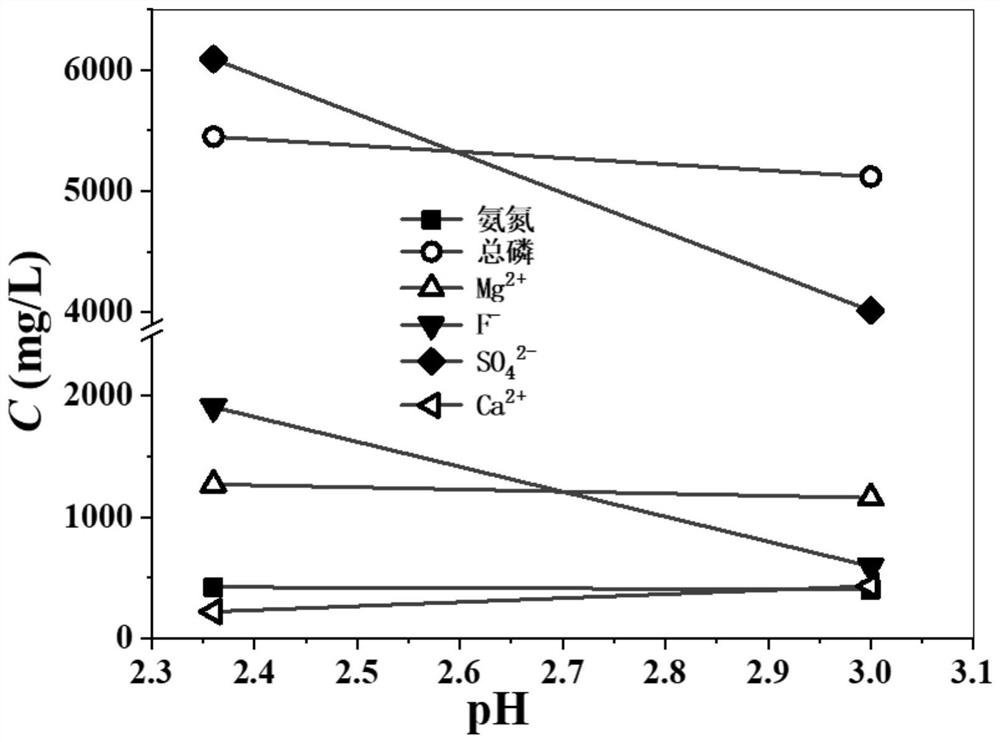

[0084] 1) The pH of leachate wastewater from a phosphogypsum storage yard is 2.4, the content of ammonia nitrogen is 367 mg / L, the content of total phosphorus is 5103 mg / L, the content of magnesium ions is 1085 mg / L, the content of fluoride ions is 1760 mg / L, and the content of sulfate ions The content is 5980mg / L, and the calcium ion content is 189mg / L, which are collected in the sump. Flow 100m 3 / h, the leachate is adjusted to pH=3.3 through the lime dosing tank 1, and after 20 minutes of reaction, the supernatant enters the reaction tank of the next stage. At this time, ammonia nitrogen, total phosphorus, and Mg 2+ , F - , SO 4 2- , Ca 2+ The concentrations were 342mg / L, 4896mg / L, 964mg / L, 429mg / L, 3762mg / L, 368mg / L in sequence.

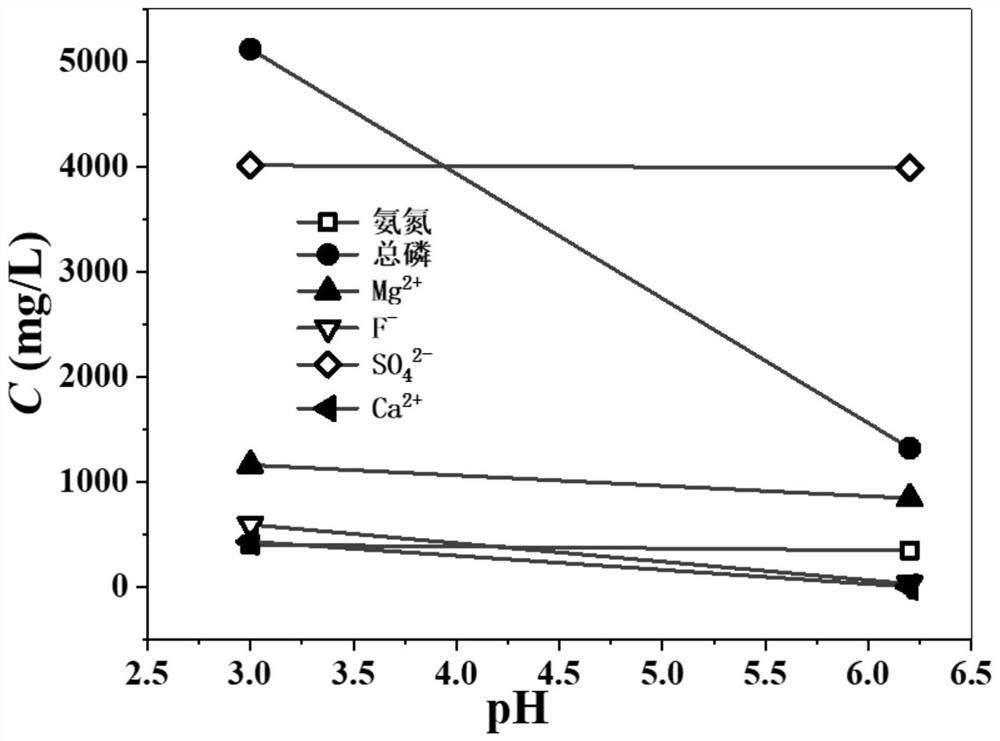

[0085] 2) Adjust the above supernatant to pH=6.4 through the lime dosing tank 1, continue to react for 20 minutes, and the supernatant enters the reaction pool of the next stage. At this time, ammonia nitrogen, total phosphorus, Mg 2+ , F ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com