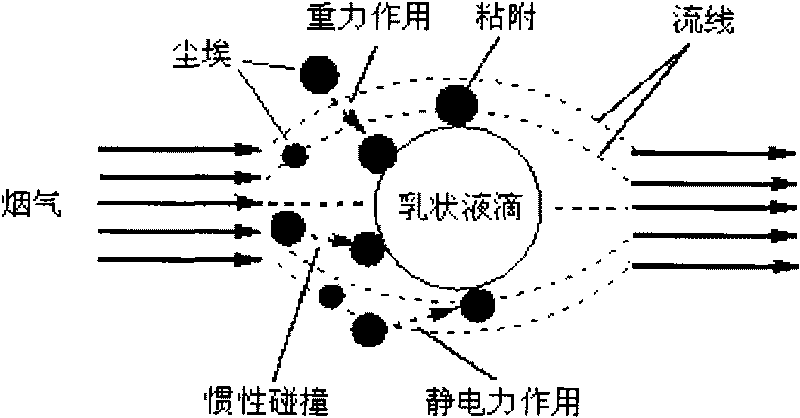

Emulsion film method for removing dust in gas fume

An emulsion liquid film and flue gas technology, which is applied in the field of flue gas dust removal and flue gas dust removal by using emulsion liquid film, can solve the problems of unsatisfactory dust removal effect and large water consumption, and achieve light specific gravity, reduce carryover, and strong adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] 1. Production of water-in-oil (W / O) type emulsion: kerosene is used as the film solvent, blue-113B is used as the surfactant, mixed according to the ratio (volume ratio) of 97:3, and fully dissolved to form the oil phase ; Gradually add water with the same volume as the oil as the internal phase liquid, and stir at a speed of 3500r / min. After the internal phase liquid is added, continue stirring for 10 minutes to obtain a water-in-oil emulsion;

[0029] 2. Flue gas dust removal: Mix the prepared emulsion with water at a volume ratio of 1:5, with a total volume of 1000ml, and stir at a low speed of 250-300r / min with a dust content of 200mg / m 3 , The flue gas with a flow rate of 2L / min is contacted for desulfurization, and the dust removal effect can be kept above 98% within 60 minutes;

[0030] 3. Demulsification and repeated emulsification of membrane phase liquid: regularly remove part of the loaded emulsion, after the emulsion is still, separate the oil layer and re-e...

example 2

[0033] 1. Prepare water-in-oil (W / O) type emulsion: use kerosene as film solvent, Span80 as surfactant, mix according to the ratio (volume ratio) of 96:4, and make it fully dissolve to form oil phase; gradually Add water with the same volume as the oil as the internal phase liquid, and stir at a speed of 3000r / min. After adding the internal phase liquid, continue stirring for 8 minutes to obtain a water-in-oil emulsion;

[0034] 2. Flue gas dust removal: mix the prepared emulsion with water at a volume ratio of 1:3, spray at a speed of 100ml / min with a total volume, and the dust content is 200mg / m 3 , The flue gas with a flow rate of 2L / min is in countercurrent contact for dust removal, and the dust removal effect can be kept above 97%;

[0035] 3. Repeated emulsification of demulsification and membrane phase liquid: Periodically separate the partly loaded emulsion into static layers, separate the oil layer and re-emulsion, and return the emulsion without demulsification to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com