Method for strengthening carbon dioxide absorption with ionic liquid-containing emulsion liquid membrane in coupling micro-fine calcium carbonate synthesis

A technology of fine calcium carbonate and ionic liquids, applied in separation methods, chemical instruments and methods, and separation of dispersed particles. moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

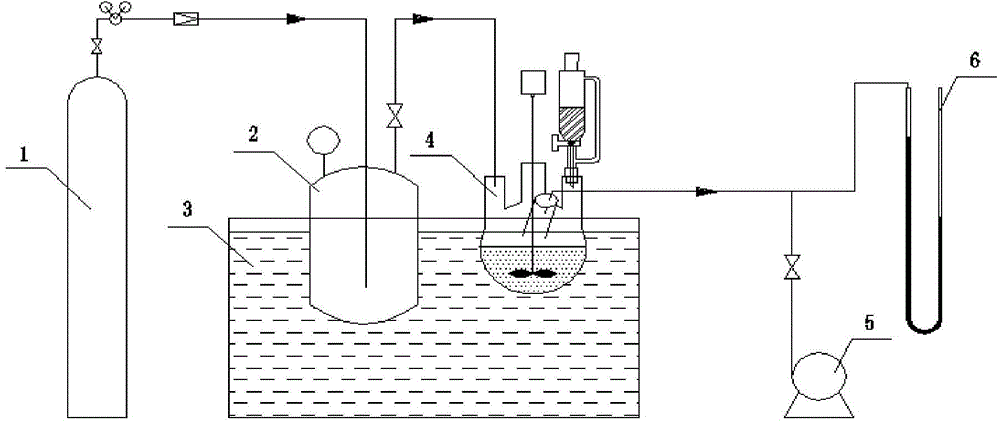

Method used

Image

Examples

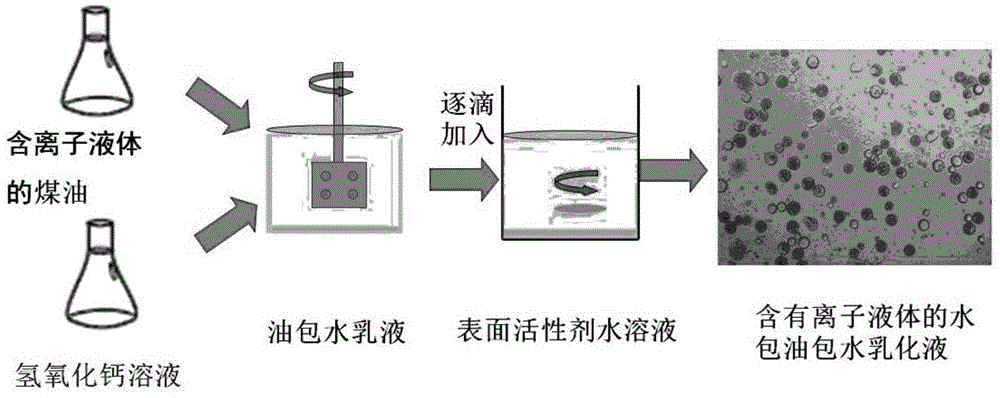

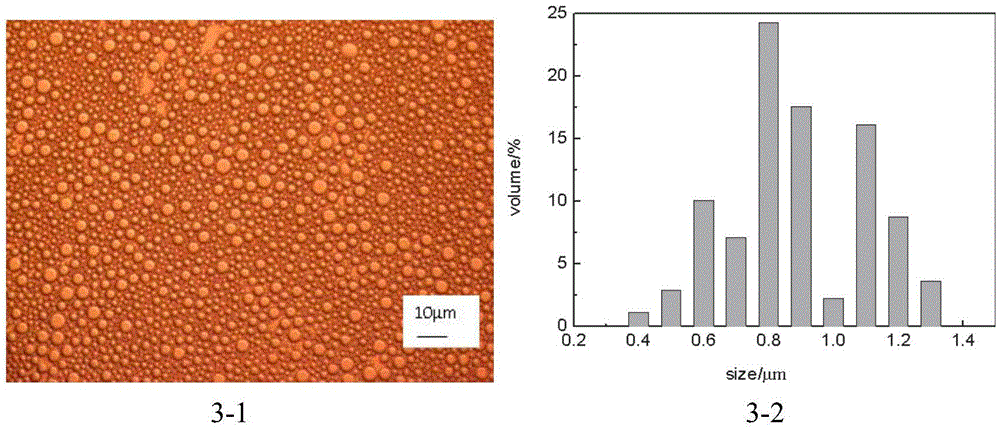

Embodiment 1

[0068] A water-in-oil emulsion film containing ionic liquids was prepared by a two-step method. First prepare the water-in-oil emulsion containing the ionic liquid, add the 1-methyl-3 methylimidazolium hexafluorophosphate ionic liquid that the volume fraction is 10% in the kerosene containing the surfactant of 0.1% by mass percentage, adopt high-speed For milk production by shearing, gradually add saturated calcium hydroxide solution at the stirring speed of 18,000 rpm, and stir for 15 minutes to prepare the required water-in-oil emulsion dispersion system containing ionic liquid, oil phase and alkali solution The volume ratio (oil-water ratio) is 2:1. The second step is to prepare the water-in-oil emulsion liquid film, in the deionized water containing 0.15% surfactant, under the condition that the stirring speed is 200 rpm, add the water-in-oil emulsion prepared in the first step dropwise , the ratio of the volume of the added water-in-oil emulsion to the volume of deionize...

Embodiment 2

[0070] A water-in-oil emulsion film containing ionic liquids was prepared by a two-step method. First prepare a water-in-oil emulsion containing an ionic liquid, add 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid with a volume fraction of 5% in kerosene containing 0.1% surfactant, and use high-speed shear For milk production, gradually add saturated calcium hydroxide solution at the stirring speed of 10,000 rpm, and stir for 10 minutes to make the required water-in-oil emulsion dispersion system containing ionic liquid, the volume of the oil phase and the alkali solution The ratio (oil-water ratio) is 2:1. The second step prepares the water-in-oil emulsion liquid film, in the deionized water containing 0.15% mass percentage surfactant, under the condition of stirring speed of 200 rpm, add the oil-in-oil prepared in the first step dropwise Water emulsion, the ratio of the volume of the water-in-oil emulsion to the volume of deionized water (milk-to-water ratio) i...

Embodiment 3

[0072] A water-in-oil emulsion film containing ionic liquids was prepared by a two-step method. First, prepare a water-in-oil emulsion containing ionic liquid, add 1-octyl-3-methylimidazolium hexafluorophosphate ionic liquid with a volume fraction of 10% in kerosene containing 0.1% surfactant, and use high-speed shear For milk production, gradually add saturated calcium hydroxide solution at the stirring speed of 15000 rpm, and stir for 10 minutes to make the required water-in-oil emulsion dispersion system containing ionic liquid, the volume of the oil phase and the alkali solution The ratio (oil-water ratio) is 2:1. The second step prepares the water-in-oil emulsion liquid film, in the deionized water containing 0.15% mass percentage surfactant, under the condition of stirring speed of 200 rpm, add the oil-in-oil prepared in the first step dropwise Water emulsion, the ratio of the volume of the water-in-oil emulsion to the volume of deionized water (milk-to-water ratio) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com