Method for separating and removing heavy-metal thallium from sintering flue gas desulfurization wastewater of ferrous metallurgy by emulsion liquid membrane

A technology of emulsion liquid membrane and sintering flue gas, which is applied in the fields of gaseous effluent wastewater treatment, chemical instruments and methods, water pollutants, etc. Simple, high removal efficiency, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

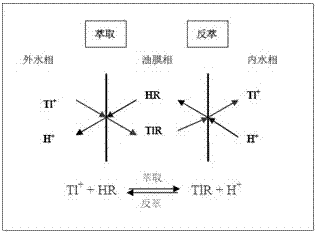

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of emulsion liquid membrane: The membrane solvent kerosene, surfactant T154, carrier P507 and liquid membrane aid PIB (polyisobutylene) with an average molecular weight lower than 1000 are used in a volume ratio of v / v=93.0:3.0:2.0: Add the ratio of 2.0 to the container, mix at a stirring speed of 350 r / min for 10 minutes to obtain a mixed solution, and then add sulfuric acid with a concentration of 1.0 mol / L to the mixed solution according to the volume ratio of the oil phase and the internal phase solution of 10.0:1.25 The aqueous solution was stirred and dispersed for 10 minutes at a speed of 6000r / min to obtain an emulsion liquid film.

[0033] (2) Contact mass transfer: mix the emulsion liquid film prepared in step (1) with the sintering flue gas desulfurization wastewater with a thallium concentration of 1.80 mg / L at the ratio of the volume ratio of the emulsion liquid film to the wastewater v / v=0.8:10.0 Mix and stir for 15 minutes at a stirring ra...

Embodiment 2

[0037] (1) Preparation of emulsion liquid membrane: The membrane solvent naphtha, surfactant SP80, carrier P204 and liquid membrane aid PIB (polyisobutylene) with an average molecular weight lower than 1000 are used in a volume ratio of v / v=95.0:2.0: Add it into the container at a ratio of 2.0:1.0, mix at a stirring speed of 300 r / min for 12 minutes to obtain a mixed solution, and then add a concentration of 1.25mol / L Aqueous sulfuric acid solution was stirred and dispersed at 7000r / min for 10min to obtain an emulsion liquid film.

[0038] (2) Contact mass transfer: The emulsion liquid film prepared in step (1) and the sintering flue gas desulfurization wastewater with a thallium concentration of 4.50mg / L were mixed at a ratio of the volume ratio of the emulsion film to the wastewater v / v=1.0:10.0 Mix and stir for 15min at a stirring rate of 300r / min, so that the thallium ions in the wastewater migrate and mass transfer and enter the internal phase.

[0039] (3) Separation of...

Embodiment 3

[0042] (1) Preparation of emulsion liquid membrane: add membrane solvent liquid paraffin, surfactant SP80, carrier P507 and membrane aid PIB with an average molecular weight lower than 1000 at a volume ratio of v / v=97.0:1.0:1.0:1.0 In the container, mix at a stirring speed of 400 r / min for 10 min to obtain a mixed solution, then add an aqueous solution of sulfuric acid with a concentration of 1.50 mol / L to the mixed solution according to the volume ratio of the oil phase to the internal phase solution of 10.0:1.5, Stirring and dispersing for 12.5min at a speed of 1 / min to obtain an emulsion liquid film.

[0043] (2) Contact mass transfer: The emulsion liquid film prepared in step (1) and the sintering flue gas desulfurization wastewater with a concentration of thallium of 7.50 mg / L were mixed at the ratio of the volume ratio of the emulsion liquid film to the wastewater v / v=1.5:10.0 Mix, and stir for 12.5min at a stirring rate of 400r / min, so that the thallium ions in the wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com