Method for reclaiming lead from waste water

A waste water and purpose technology, applied in the field of lead waste water treatment, can solve the problems of high price and toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

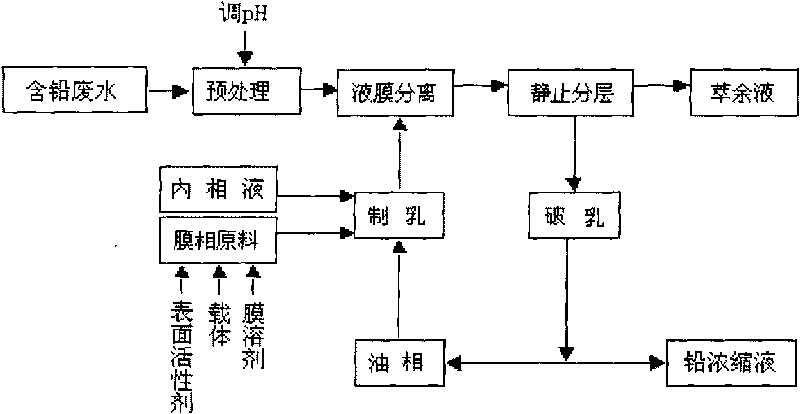

Image

Examples

Embodiment Construction

[0006] The present invention first adopts L113A as surfactant, uses N7301 as carrier, uses industrial kerosene as film solvent, and takes acidic solution as internal water phase to prepare emulsion; secondly, the prepared emulsion is dispersed in lead-containing waste water, by contacting waste water The lead in the liquid is transferred to the internal phase liquid through the liquid film, and is enriched in the internal phase liquid; through static layering, the loaded emulsion is electrostatically demulsified, the oil phase is used to re-prepare the emulsion, and the internal phase of the concentrated lead The phase solution is used to prepare lead salts.

[0007] The present invention is achieved through the following technical solutions, including the following specific steps:

[0008] 1. Preparation of emulsion

[0009] (1) In an emulsifying cup, dissolve 3-5% (v / v) of L113A surfactant and 3-5% (v / v) of N7301 carrier in kerosene film solvent.

[0010] (2) While stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com