Method for removing cyanides in cyaniding wastewater by use of emulsion liquid membrane technology

A technology of emulsion liquid membrane and cyanide wastewater, which is applied in chemical instruments and methods, water/sewage treatment, extraction water/sewage treatment, etc., can solve the problems of insufficient treatment depth, direct and convenient destruction, waste of resources, etc., and achieve enrichment Short cycle, easy follow-up processing, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

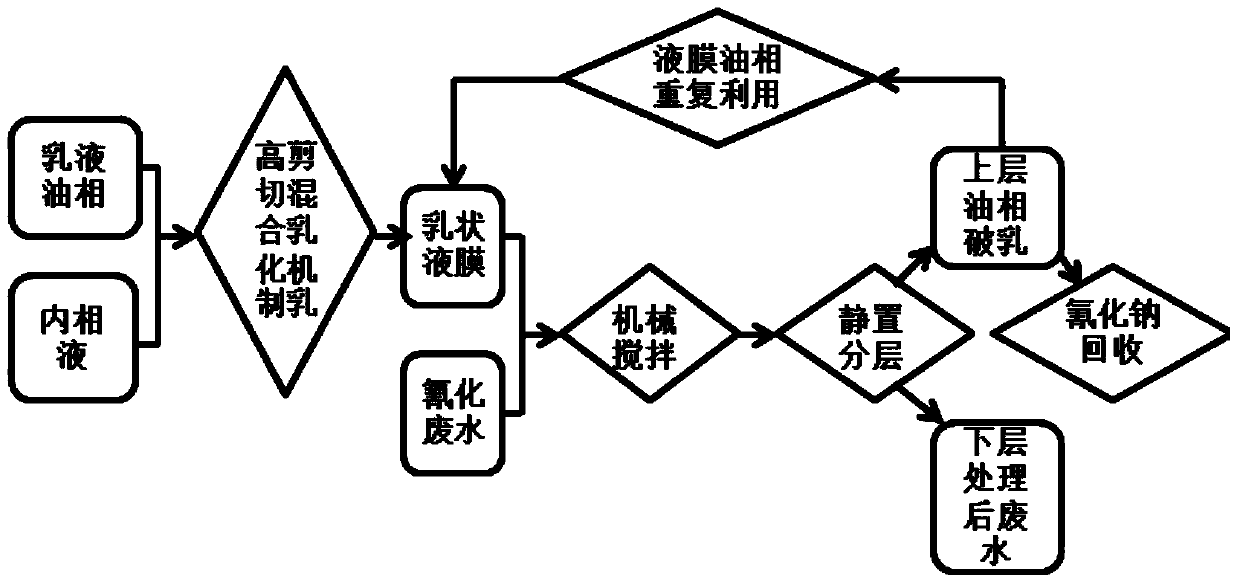

[0020] like figure 1 As shown, the emulsion preparation of the present embodiment is that TOA, liquid paraffin, Span-80, kerosene, sodium hydroxide internal phase liquid are respectively in volume ratio 2:1:2:95:100, 2:1:3:94: 100, 2:1:4:93:100 mix well and set aside. The mixed solution was mixed under a high-shear mixing emulsifier at a rotation speed of 2300r / min for 10min to obtain an emulsion liquid film. Adjust the pH of the cyanide wastewater to 4, mix the emulsion film and the cyanide wastewater evenly at a volume ratio of 1:7, and mechanically stir and contact them for 15 minutes at a speed of 250r / min. The above mixed solution was left to stand at room temperature for phase separation to obtain a liquid film and a treated aqueous phase. The liquid film phase and the internal water phase are mechanically stirred to break the demulsification, and then stand still to obtain a sodium cyanide-enriched water phase, and the cyanide is recovered. After treatment, the remov...

Embodiment 2

[0022] like figure 1 As shown, the emulsion preparation of this embodiment is to mix TOA, liquid paraffin, Span-80, kerosene, and sodium hydroxide internal phase liquid in a volume ratio of 2:1:4:93:100, respectively. The mixed solution was mixed under a high-shear mixing emulsifier at a rotation speed of 2300r / min for 10min to obtain an emulsion liquid film. For the cyanidation wastewater with an initial concentration of 644.46mg / L, 483.35mg / L, and 322.23mg / L, the pH of the wastewater was adjusted to 4, and the emulsion liquid film and the cyanide wastewater were mixed evenly at a volume ratio of 1:7. Contact with mechanical stirring for 15 minutes at a speed of 1 / min. The above mixed solution was left to stand at room temperature for phase separation to obtain a liquid film and a treated aqueous phase. The liquid film phase and the internal water phase are mechanically stirred to break the demulsification, and then stand still to obtain a sodium cyanide-enriched water phas...

Embodiment 3

[0024] like figure 1 As shown, the emulsion preparation of this embodiment is to mix TOA, liquid paraffin, Span-80, kerosene, and sodium hydroxide internal phase liquid in a volume ratio of 2:1:4:93:100, respectively. The mixed solution was mixed under a high-shear mixing emulsifier at a rotation speed of 2300r / min for 10min to obtain an emulsion liquid film. Adjust the pH of the wastewater to 4, mix the emulsion liquid film and cyanide wastewater evenly at a volume ratio of 1:7, and mechanically stir and contact them for 15 minutes at a speed of 250r / min. The above mixed solution was left to stand at room temperature for phase separation to obtain a liquid film and a treated aqueous phase. The liquid film phase and the internal water phase are mechanically stirred to demulsify and then left to stand to obtain a water phase rich in sodium cyanide, the cyanide is recovered, and the obtained oil phase is reused many times. The emulsion reused many times continued to treat the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com