Novel rifamycin SV sodium salt production technology

A technology of rifamycin and production process, which is applied in the field of raw material drug production process, can solve the problems of no report, low yield, high impurity content, etc., and achieve the effect of ensuring quality, high product yield and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

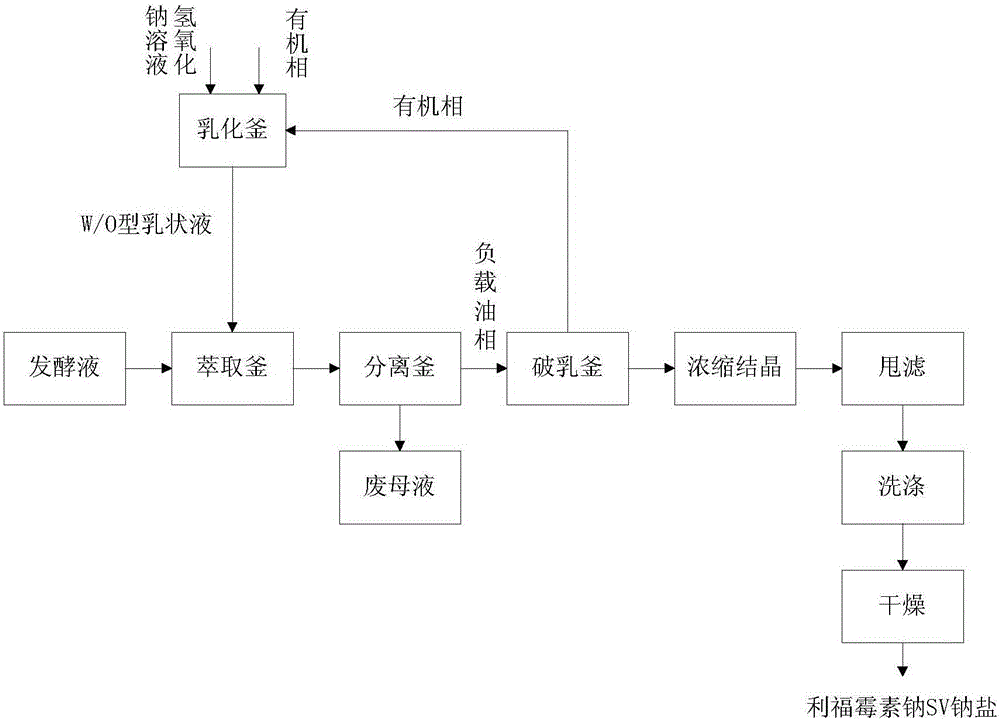

Method used

Image

Examples

Embodiment 1

[0031] 1) Extraction. Starting from the fermented liquid of the traditional process, put 100KG of fermented liquid into the reaction kettle, and pump the fermented liquid and 12.5KG of the W / O emulsion liquid film obtained in the emulsification tank into the extraction tank for extraction at 25°C to 30°C The time is 30 minutes.

[0032] The emulsion is prepared by mixing 30KG organic phase and 15KG internal water phase in a high-speed shear emulsifier at a speed of 4000 rpm to form a W / O emulsion liquid film; wherein the organic phase is a surfactant, a film solvent Composed with carrier, the inner water phase is 20% (m / m) sodium bicarbonate solution; the quality of sulfonated kerosene is 37.6KG, the quality of surfactant L-113A is 1.2KG, and the quality of N263 is 1.2KG.

[0033] 2) Primary separation: put the extracted mixed solution in the separation tank for 60 minutes to separate the mixed solution under gravity, the upper layer is the loaded emulsion, and the lower laye...

Embodiment 2

[0037] 1) Extraction. Taking the fermented liquid of the traditional process as the starting point, the fermented liquid and 20KG of the W / O emulsion liquid film obtained in the emulsification tank are pumped into the extraction device, and the extraction time is 45 minutes at 25°C to 30°C.

[0038] The emulsion is prepared by mixing 30KG organic phase and 15KG internal water phase in a high-speed shear emulsifier at a speed of 3500 rpm to form a W / O emulsion liquid film; wherein the organic phase is a surfactant, a film solvent Composed with carrier, the inner water phase is 15% (m / m) sodium hydroxide solution; the mass of n-hexane is 37.6KG, the mass of surfactant L-113B is 1.2KG, and the mass of TBP is 1.2KG.

[0039] 2) Primary separation: put the extracted mixed solution in the separation tank for 60 minutes to separate the mixed solution under gravity, the upper layer is the loaded emulsion, and the lower layer is the waste mother liquor; the upper layer enters the demul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com