Recyclable environment-friendly water purifying agent and method for preparing same

A water purifying agent and an environmentally friendly technology, which is applied in chemical instruments and methods, water/sewage treatment, special compound water treatment, etc. It can solve the problems that the sedimentation effect is not as good as that of polyacrylamide and sludge treatment is difficult, and the preparation method is simple and easy. Good, low price, good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

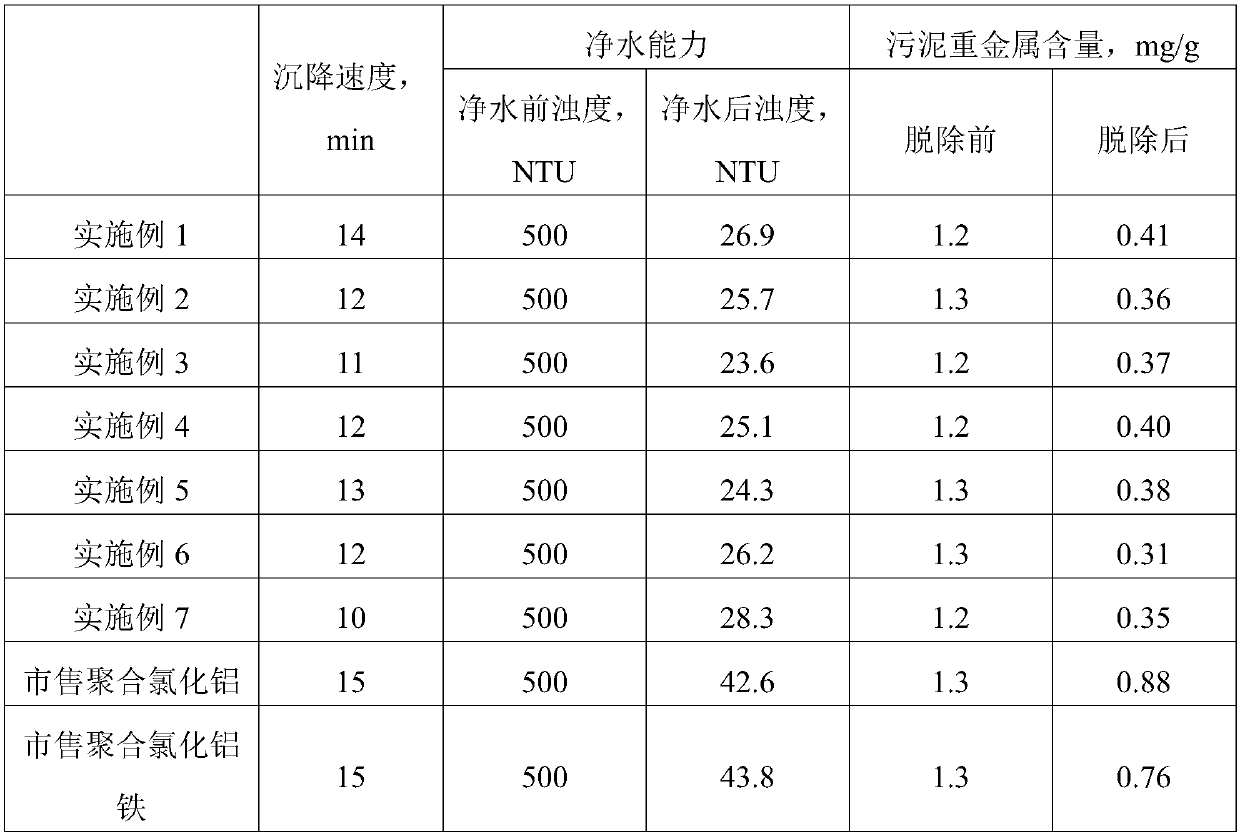

Examples

Embodiment 1

[0027] A recyclable environment-friendly water purifier, the water purifier has a core-shell structure, the core layer of the core-shell structure is nano magnetic particles, the shell layer of the core-shell structure is an emulsion liquid film, and the emulsion An inorganic polymer coagulant is deposited outside the membrane.

[0028] The particle diameter of the magnetic particles is 1 nm.

[0029] The raw material of the magnetic particles is ferric oxide, and the purity of the ferric oxide is 99.6%.

[0030] The inorganic polymer coagulant is polyaluminum chloride.

[0031] Correspondingly, a kind of preparation method as above-mentioned recyclable environment-friendly water purifying agent, it comprises the following steps:

[0032] S1: Emulsion liquid film preparation: the film composed of 5% polyethylene glycol, 8% triethanolamine phosphate, 269% N,N-diethyl phosphoramidite di-tert-butyl and 58% palm oil Layer oil phase, the internal phase is 0.1mol / L sodium hydroxi...

Embodiment 2

[0039] A recyclable environment-friendly water purifier, the water purifier has a core-shell structure, the core layer of the core-shell structure is nano magnetic particles, the shell layer of the core-shell structure is an emulsion liquid film, and the emulsion An inorganic polymer coagulant is deposited outside the membrane.

[0040] The particle diameter of the magnetic particles is 10 nm.

[0041] The raw material of the magnetic particles is composed of 5 parts by weight of ferric oxide and 2 parts by weight of ferric oxide.

[0042] Both the purity of the ferric oxide and ferric oxide are 99.5%.

[0043] The inorganic polymer coagulant is polyaluminum chloride.

[0044] Correspondingly, a kind of preparation method as above-mentioned recyclable environment-friendly water purifying agent, it comprises the following steps:

[0045] S1: Emulsion liquid film preparation: a film composed of 16% polyethylene glycol, 13% triethanolamine phosphate, 26% N,N-diethyl phosphoram...

Embodiment 3

[0052] A recyclable environment-friendly water purifier, the water purifier has a core-shell structure, the core layer of the core-shell structure is nano magnetic particles, the shell layer of the core-shell structure is an emulsion liquid film, and the emulsion An inorganic polymer coagulant is deposited outside the membrane.

[0053] The particle diameter of the magnetic particles is 5 nm.

[0054] The raw material of the magnetic particles is ferric oxide, and the purity of the ferric oxide is 99.4%.

[0055] The inorganic polymer coagulant is polyaluminum ferric chloride.

[0056] Correspondingly, a kind of preparation method as above-mentioned recyclable environment-friendly water purifying agent, it comprises the following steps:

[0057] S1: Emulsion liquid film preparation: a film composed of 12% polyethylene glycol, 8% triethanolamine phosphate, 30% N,N-diethyl phosphoramidite di-tert-butyl and 50% palm oil Layer oil phase, the inner phase is 0.3mol / L sodium hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com