Emulsion liquid membrane for gold extraction

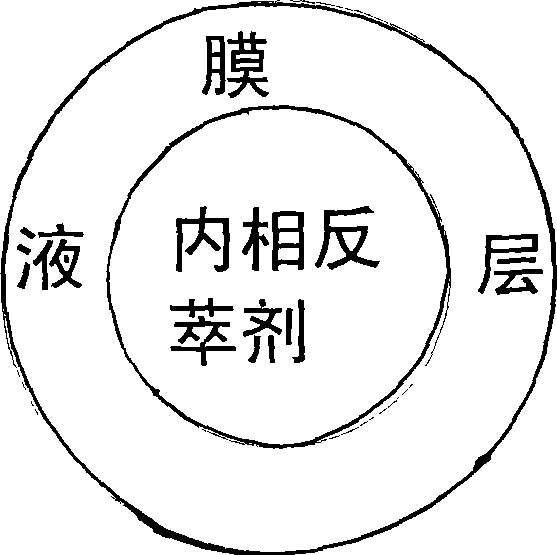

A technology of emulsified liquid film and liquid film, which is applied in the field of chemical industry, can solve the problems of reduced range and effect, poor stability of emulsion liquid film, etc., and achieve the effect of good stability, strong practicability and improved extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

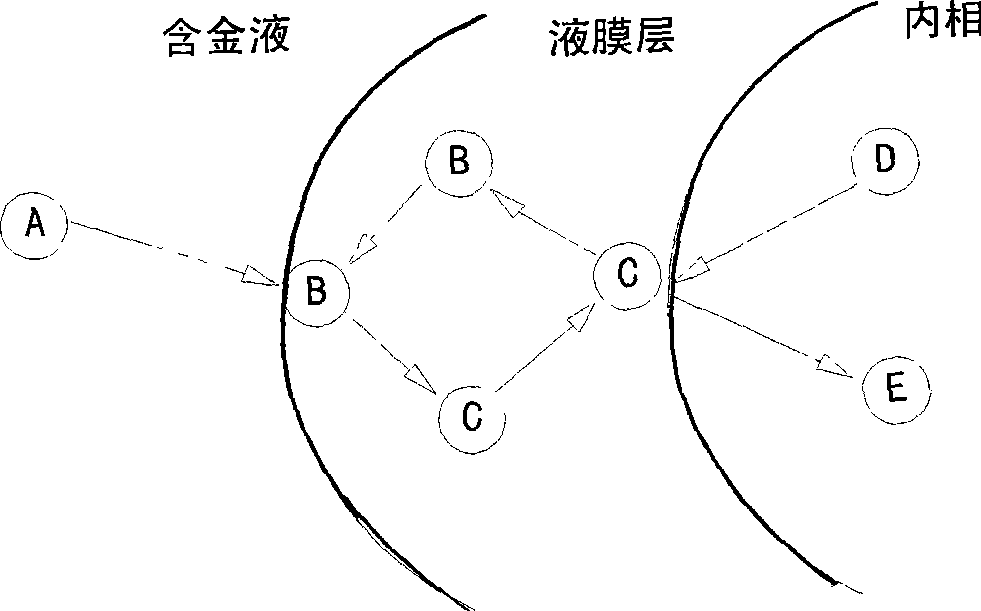

Method used

Image

Examples

Embodiment 1

[0025] Raw material name volume percentage (%)

[0026] Sulfonated kerosene 83

[0027] n-octylamine 8

[0028] Monosuccinimide 5

[0029] liquid paraffin 2

[0030] Methyltrioctylamine chloride 2

[0031] The emulsified liquid film layer made according to the above ratio and the internal phase extraction agent are mixed at a ratio of 1:1 and stirred at a high speed to form an emulsified liquid film for gold extraction, and the internal phase extraction agent is 1% NaOH aqueous solution;

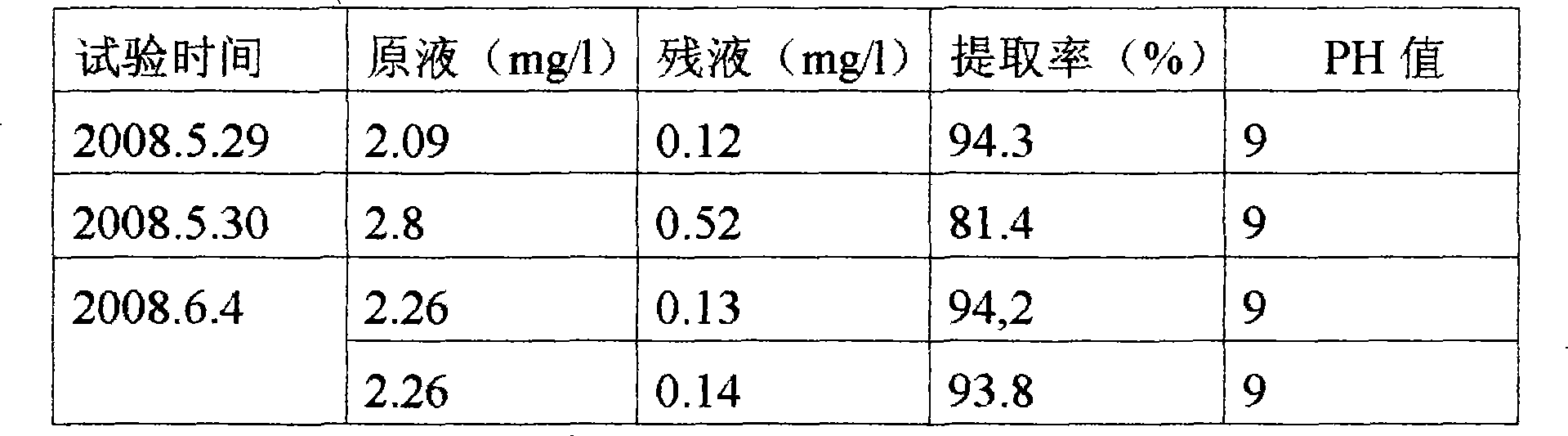

[0032] Before each gold extraction, first add acid to adjust the pH value of the gold-containing solution at 7-10, then slowly add the emulsified liquid film and stir according to the ratio of 1:5 of the emulsified liquid film reagent to the gold-containing solution, and the stirring speed 200rpm, so that the emulsion is evenly distributed, and the gold can enter the inner phase after 10 minutes of extraction time. The experimental results are shown in Table 1

[0033] Liquid film formu...

Embodiment 2

[0037] Get the following raw material ratio to make the emulsified liquid film layer:

[0038] Raw material name volume percentage (%)

[0039] Sulfonated kerosene 85

[0040] n-octylamine 10

[0041] Monosuccinimide 3

[0042] liquid paraffin 1

[0043] Methyltrioctylamine chloride 1

[0044] Mix the emulsified liquid film layer prepared according to the above raw material ratio with the internal phase extraction agent at a ratio of 1:1 and stir at a high speed to form an emulsified liquid film for gold extraction, and the internal phase extraction agent is 1% NaOH aqueous solution;

[0045] Before each gold extraction, first add acid to adjust the pH value of the gold-containing solution to 9, then slowly add and stir according to the ratio of the emulsified liquid film to the gold-containing solution 1:5, and the stirring speed is 230rpm, so that the emulsion is distributed Uniform, gold extraction time is 15 minutes, gold can enter the inner phase, the experimental re...

Embodiment 3

[0050] Get the following raw material ratio to make the emulsified liquid film layer:

[0051] Raw material name volume percentage (%)

[0052] Sulfonated kerosene 84

[0053] n-octylamine 7

[0054] Monosuccinimide 4

[0055] liquid paraffin 2

[0056] Methyltrioctylamine chloride 3

[0057] Mix the emulsified liquid film layer prepared according to the above raw material ratio with the internal phase extraction agent at a ratio of 1:1 and stir at a high speed to form an emulsified liquid film for gold extraction, and the internal phase extraction agent is 1% NaOH aqueous solution;

[0058] Before extracting gold each time, first add acid to adjust the pH value of the gold-containing solution at 6-10, then slowly add and stir according to the ratio of 1:5 of the emulsified liquid film reagent to the gold-containing solution, and the stirring speed is 250rpm, The emulsion is evenly distributed, and the gold-containing liquid can enter the inner phase after 20 minutes of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com