Closed-loop circulation drying system based on two-stage solution dehumidification

A solution dehumidification and closed-circuit circulation technology, which is applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of limited dehumidification capacity, achieve high dehumidification efficiency, large mass transfer driving force, and reduce system performance. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

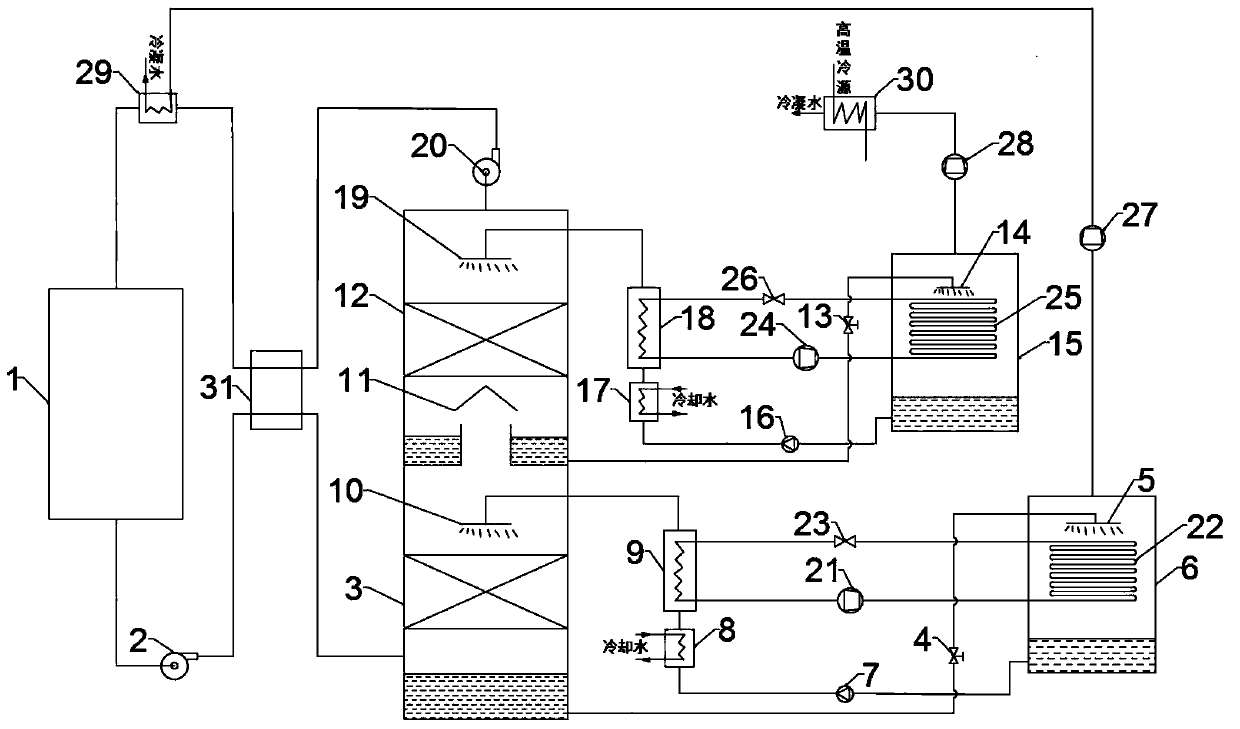

[0042] The schematic diagram of the device structure of the closed-loop drying system based on two-stage solution dehumidification in this embodiment is as follows: figure 1 shown. control figure 1 , both the high-pressure steam condenser 29 and the low-pressure steam condenser 30 can adopt a heat exchanger structure.

[0043] After the hygroscopic saline solution in the primary vacuum regeneration tank 6 boils, the moisture in the hygroscopic saline solution becomes water vapor, which is pressurized by the compressor III 27 and enters the high-pressure steam condenser 29 to condense into liquid water, which is condensed and released The heat is used to heat the drying medium air (that is, the low-temperature and low-humidity drying medium drawn by the second fan 20 is preheated through the cold fluid passage of the heat exchange device 31, and then further heated through the cold fluid passage of the high-pressure steam condenser 29 to form High-temperature and high-humidit...

Embodiment 2

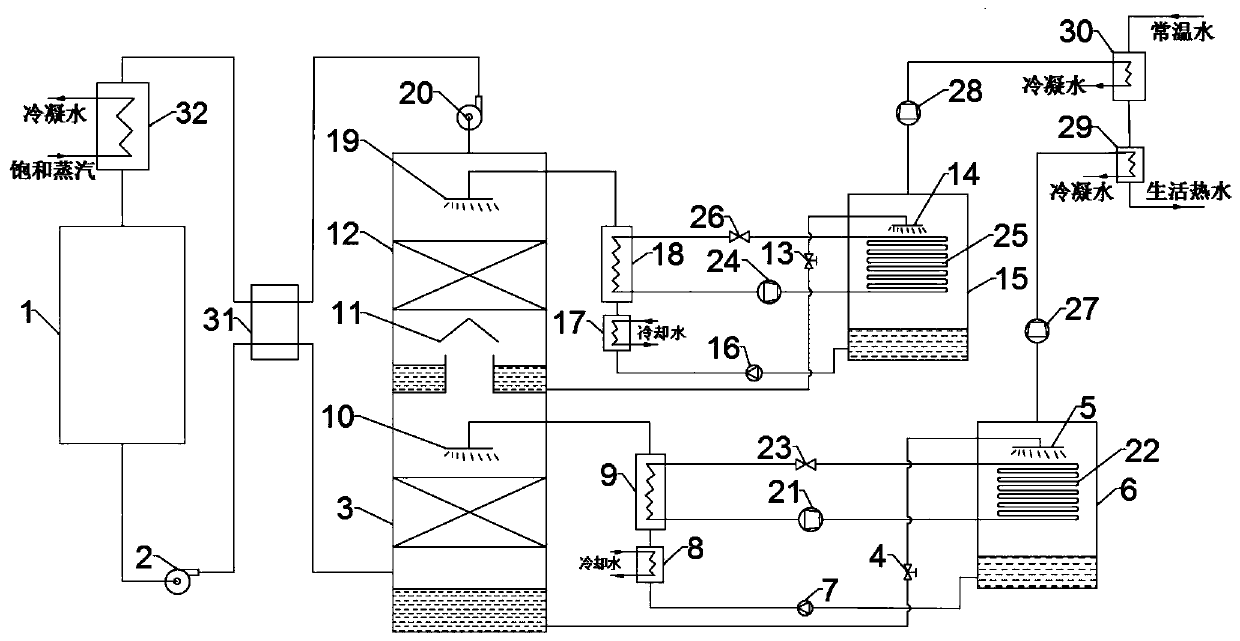

[0047] The schematic diagram of the device structure of the closed-loop drying system based on two-stage solution dehumidification in this embodiment is as follows: figure 2 shown. control figure 2 , both the high-pressure steam condenser 29 and the low-pressure steam condenser 30 can adopt a heat exchanger structure.

[0048] control figure 2 , the top of the first-stage vacuum regeneration tank 6 is connected by a pipeline through the hot fluid channel of the compressor III 27 and the high-pressure steam condenser 29, and the compressor IV 28 and the low-pressure steam condenser 30 of the second-stage vacuum regeneration tank 15 top pass through The hot fluid passages are connected by pipelines, and normal temperature water flows through the cold fluid passages of the low-pressure steam condenser 30 and the cold fluid passages of the high-pressure steam condenser 29 in sequence, and is heated to form domestic hot water. Both the heat of condensation in the high-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com