Hypergravity mass transfer apparatus

A super-gravity, shell technology, applied in air conditioning, chemistry, thermal power, environmental protection and refrigeration, chemical industry, can solve the problems of single function, large air flow resistance, etc., to expand the contact area, reduce flow resistance, and good separation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

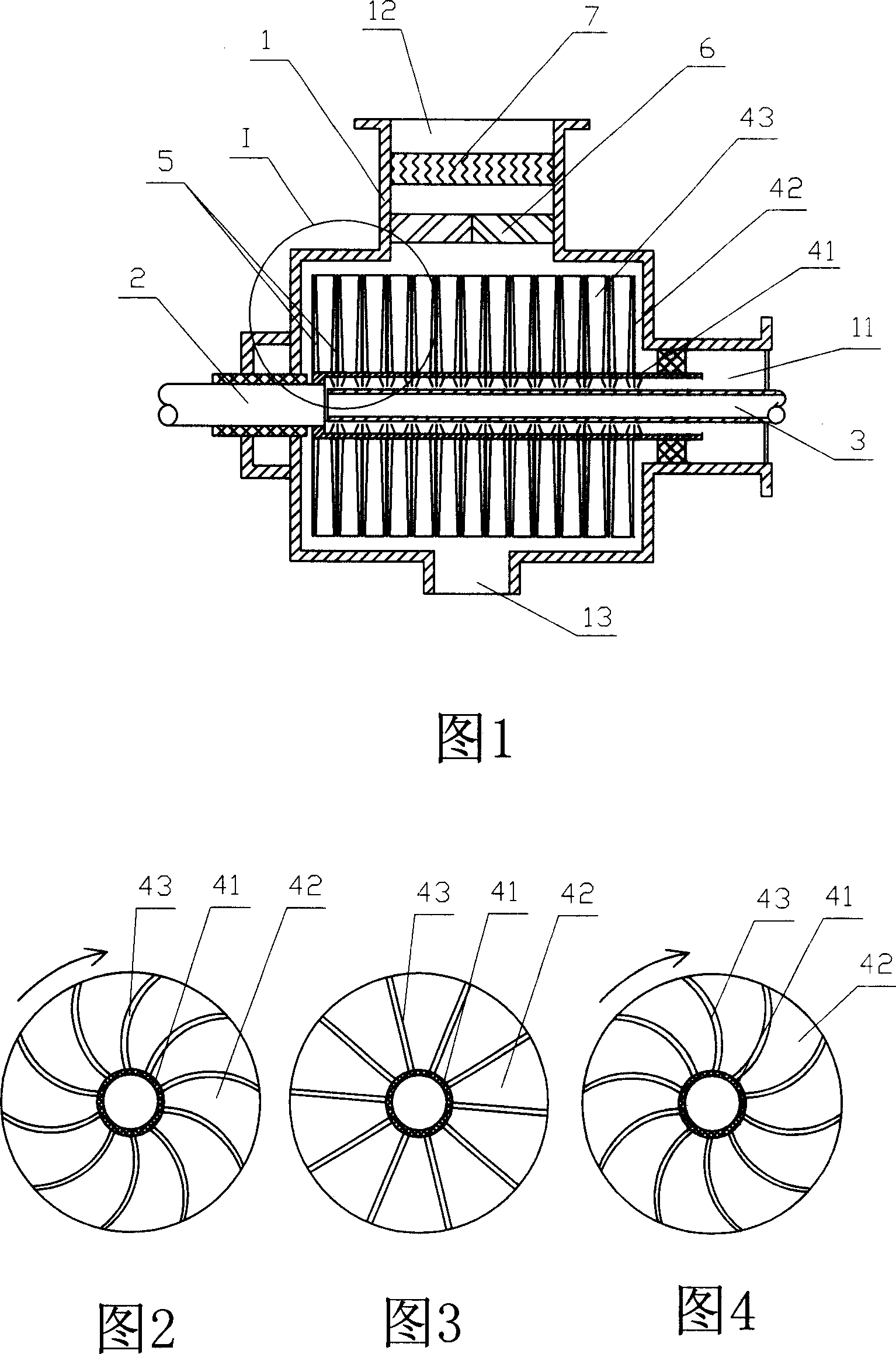

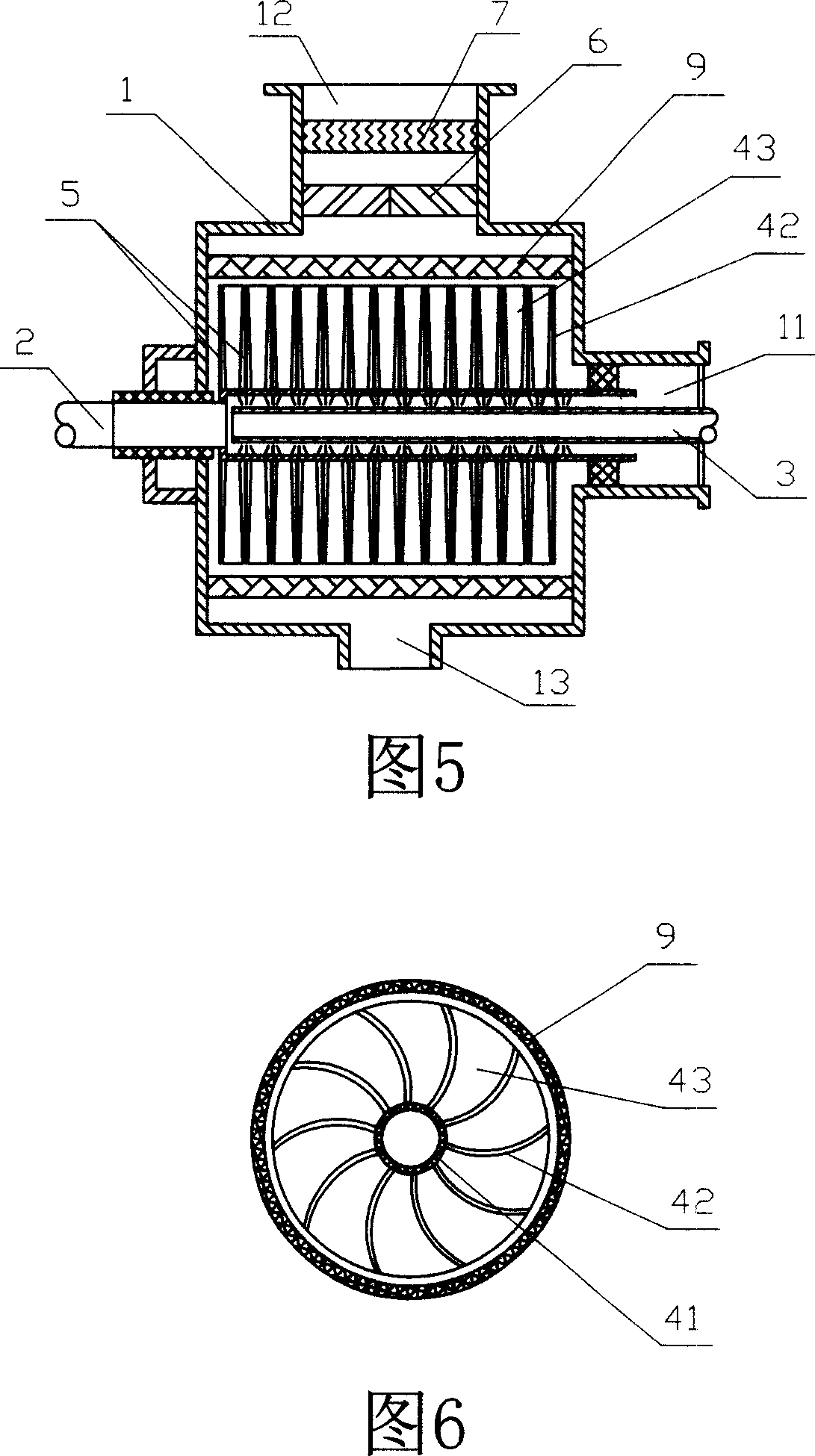

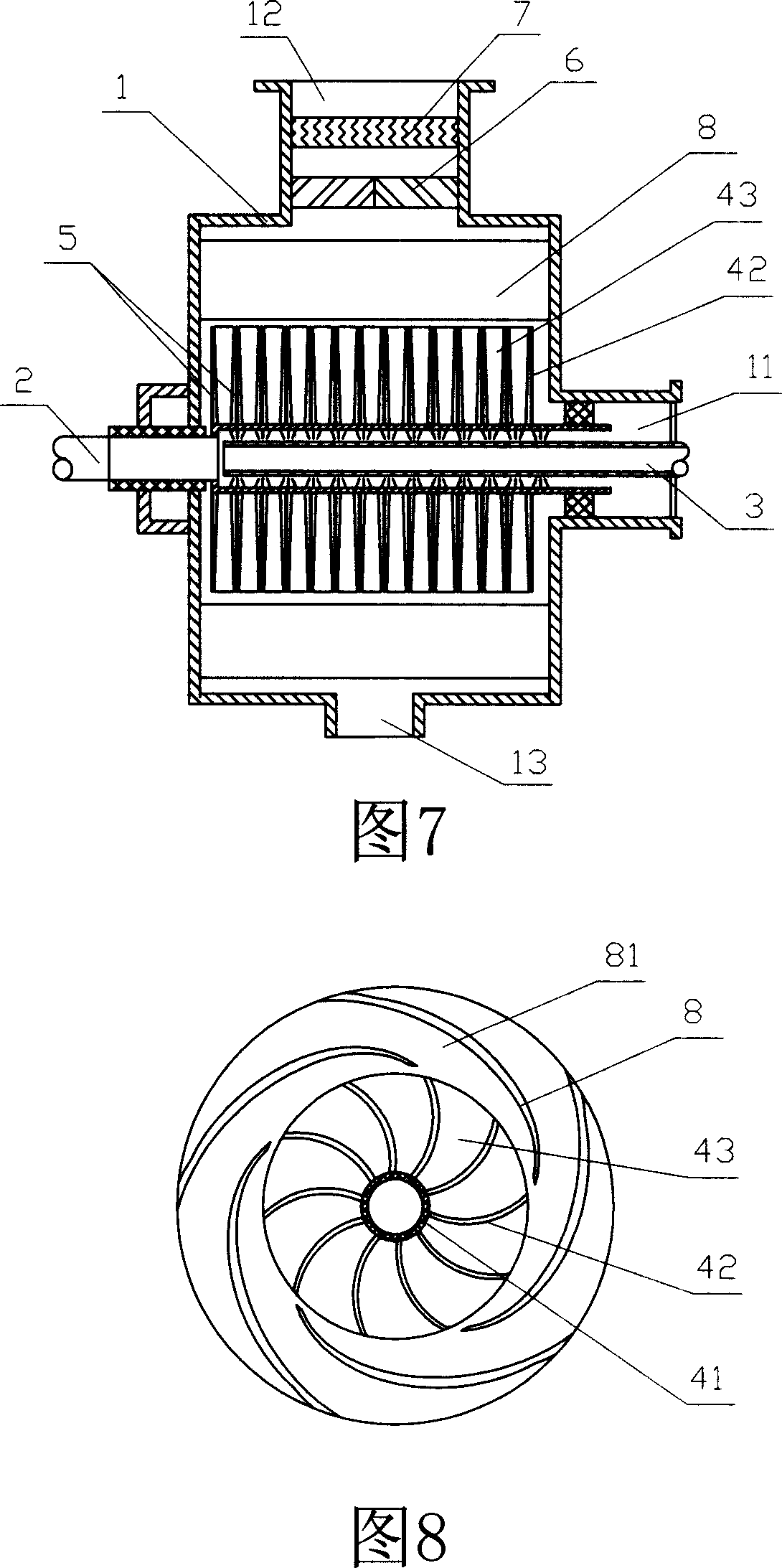

[0024] As shown in Fig. 1 and Fig. 11, it is an embodiment of the supergravity mass transfer device of the present invention, including a casing 1, a rotating shaft 2 arranged on the casing 1, and a liquid inlet pipe 3, and the casing is provided with an air inlet 11 and an exhaust port 12 and a liquid discharge port 13, the liquid discharge port 13 is located at the bottom of the shell 1, and the liquid discharge port is a liquid discharge port with a liquid seal to prevent gas from being discharged from the liquid discharge port. The rotating shaft 2 is connected with a swivel, and the swivel body can The rotating shaft 2 rotates at a high speed to form a supergravity centrifugal force field, which includes a cylindrical central shaft 41 connected to the end of the rotating shaft 2, several coaxial plates 42 arranged on the outer wall of the cylindrical central shaft 41 and arranged on each Several vanes 43 on the cylindrical central shaft 41 between the parallel plates 42, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com