A kind of method utilizing sulfuric acid tail gas to dry ammonium phosphate

A technology of sulfuric acid tail gas and ammonium phosphate, applied in the direction of drying gas arrangement, drying, dryer, etc., can solve the problem of not being utilized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

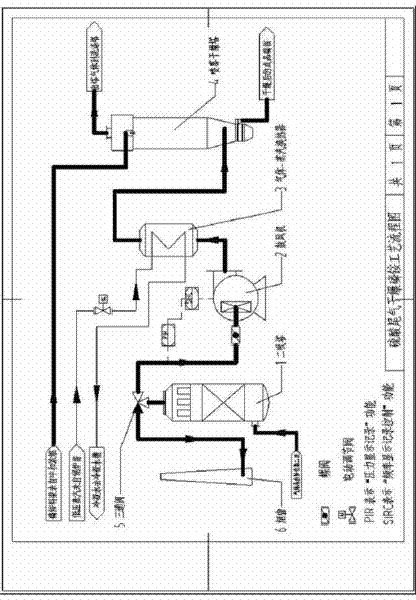

[0009] exist figure 1 In the process, the gas at the outlet of the sulfuric acid secondary absorption tower 1 is heated to 140-160°C by the gas-steam heat exchanger 3 under the action of the blower 2, and then sent to the bottom of the spray drying tower 4. 4. The ammonium phosphate slurry sprayed from the upper part is mixed and contacted, and the heat and moisture are transferred between the gas and liquid phases. The moisture content of the dried product is ≤ 3%, and it is discharged from the lower part of the spray drying tower 4, and the gas at the outlet of the spray drying tower 4 enters the washing process. The tower is emptied after dust removal and desulfurization. In order to prevent the tail gas sucked by the blower 2 from affecting the operation of the sulfuric acid plant, the blower 2 uses a frequency converter to control the motor speed, and installs a pressure gauge on the outlet pipe of the second suction tower to detect the pressure on the outlet pipe of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com