Plasma flying ash melting tail gas wet-purification process

A plasma and wet purification technology, applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of poor quality and high content of heavy metals, and achieve large mass transfer driving force, high separation efficiency, and high transmission efficiency. Effect of Heat and Mass Transfer Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

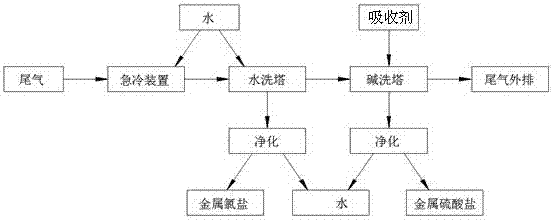

[0029] like figure 1 Shown is the flow chart of the wet purification process of the plasma fly ash fusion tail gas of the present invention.

[0030] The waste incineration fly ash is processed by the plasma melting furnace, and the exhaust gas enters the dynamic wave device through the high-temperature pipeline to reduce the temperature below 100°C, and then enters the water washing tower, in which the HCl gas is completely removed; the tail gas from which the HCl is removed enters the alkali Washing tower, remove SO in alkali washing tower 2 Wastewater after gas, water washing and alkali washing are neutralized, precipitated and separated through their respective sewage treatment devices to remove heavy metals and suspended solids in the sewage, and the final concentrated brine is respectively passed through an evaporation crystallizer to obtain chloride salts and sulfates. It is used as a dyeing aid in the printing and dyeing industry; the final clean tail gas is drawn by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com