Ultrasonic wave-pulse vacuum synergistic fish meat salting method

A pulsed vacuum and ultrasonic technology, applied in food ultrasonic treatment, meat/fish preservation, meat/fish preservation through radiation/electrical treatment, etc., can solve the problems of low curing rate and increased curing rate, and achieve enhanced transmission Quality driving force, promotion of contact, and effect of avoiding spoilage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An ultrasonic-pulse vacuum synergistic fish marinating method, comprising the following steps:

[0038] S1: After slaughtering fresh grass carp (weight 2kg), remove the scales and internal organs, divide the grass carp into two parts along the parallel direction of the fish bones, and then cut the fish into pieces with a thickness of 2cm along the back, and put them in a refrigerator (2°C) Refrigerate for 12h.

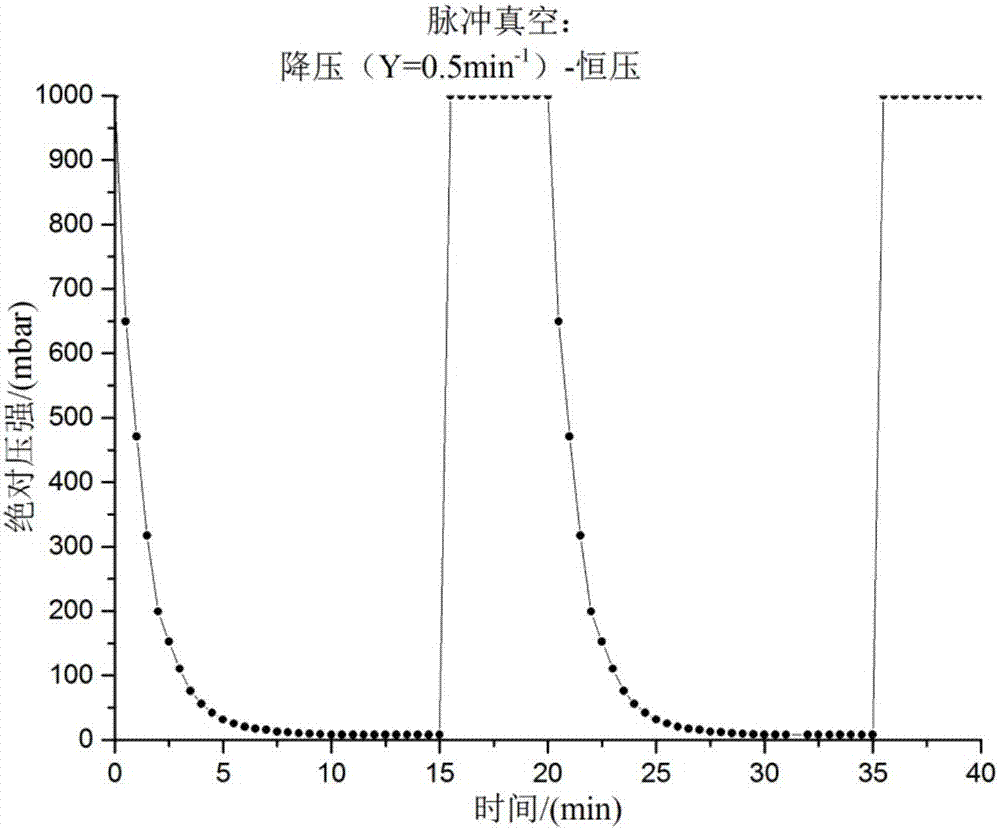

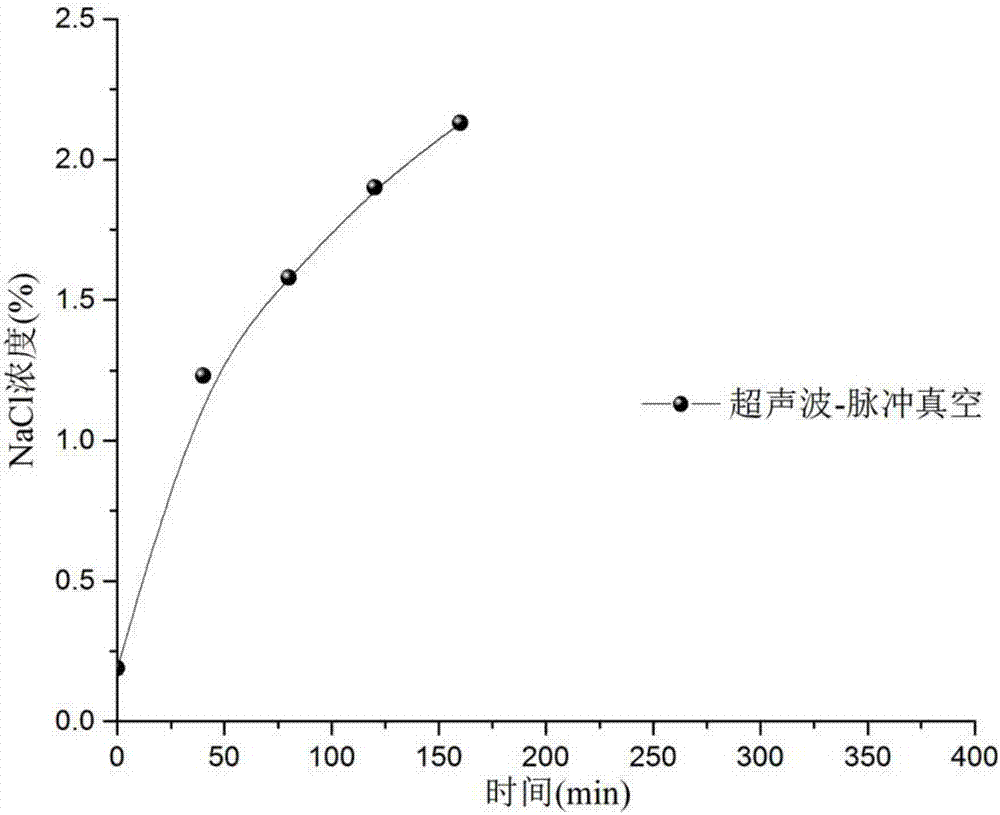

[0039] S2: put the refrigerated fish pieces into a low-temperature salt solution with a mass concentration of 6% and a temperature of 4°C, and the mass ratio of the salt solution to the fish pieces is 20:1. Then transfer the fish pieces together with the low-temperature salt solution to the ultrasonic tank of the ultrasonic generator, and then transfer the ultrasonic tank together with the salt solution and the fish pieces to the vacuum box of the vacuum precooler, so that the fish meat and the salt solution can be separated from each other. The temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com