Hot water boiler and water heating method

A hot water boiler and boiler technology, applied in fluid heaters, lighting and heating equipment, sustainable manufacturing/processing, etc., can solve the problems of waste of resources, high cost of use, large maintenance, etc. The effect of reaction speed and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

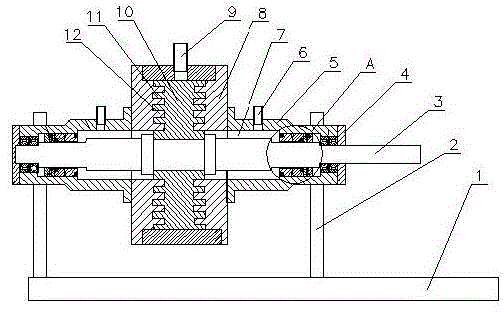

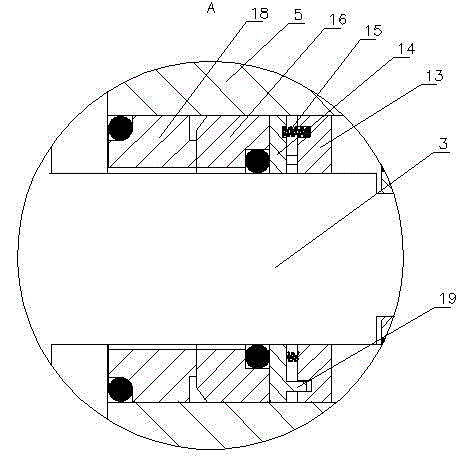

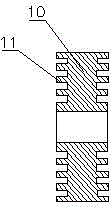

[0031] Such as Figure 1-4The hot water boiler shown includes a base 1, a furnace body 8, a rotating shaft 3, a cavitation heating rotor 10, a bearing body, and a bearing gland. The base 1 is provided with a left bearing body and a right bearing body 5 opposite to each other via a bracket 2. The rotating shaft 3 is installed in the left bearing body and the right bearing body 5 through bearings, and the left and right ends of the furnace body 8 are respectively sealed and fixedly connected with the right end of the left bearing body and the left end of the right bearing body. Located in the center of the furnace body, the bearings are arranged in the left end of the left bearing body and in the right end of the right bearing body. The left end of the left bearing body and the right end of the right bearing body are provided with a bearing gland 4; the left bearing body between the furnace body and the bearing and the side wall of the right bearing body are respectively provide...

Embodiment 2

[0034] Such as Figure 5-7 The hot water boiler shown includes a base 1, a furnace body 8, a rotating shaft 3, a cavitation heating rotor, a left bearing body, a right bearing body 5, and a bearing gland 4. The base is oppositely provided with a left bearing body and a right bearing The body 5 and the rotating shaft 3 are installed in the left bearing body and the right bearing body through bearings. The left and right ends of the furnace body 8 are sealed and fixedly connected with the right end of the left bearing body and the left end of the right bearing body. In the center of the furnace body, the bearings are arranged in the left end of the left bearing body and the right end of the right bearing body, and bearing glands 4 are arranged on the left end of the left bearing body and the right end of the right bearing body; The device is provided with two water-splitting electrodes 21 and 23 on the side wall of the furnace body. When in use, the two water-splitting electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com