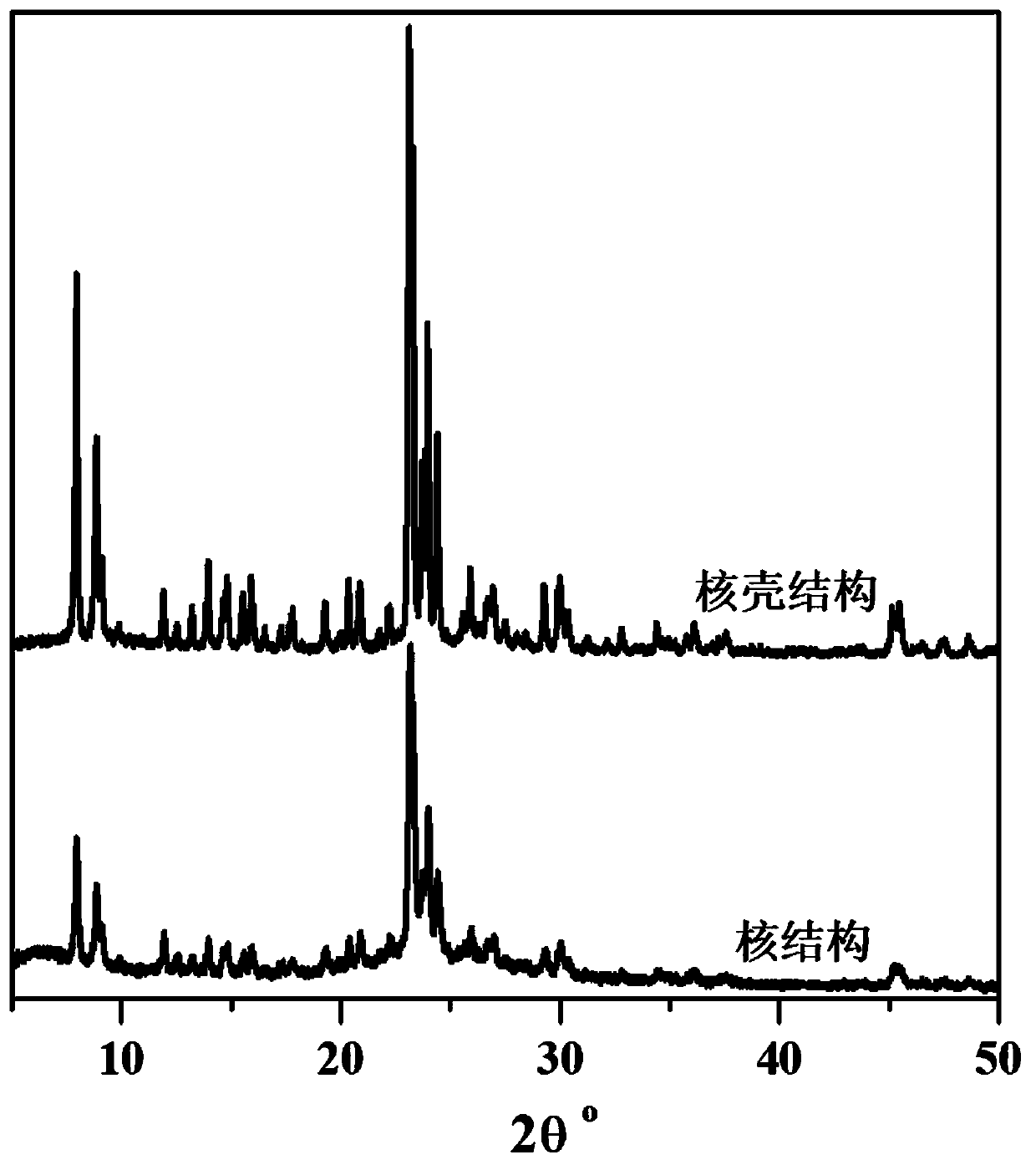

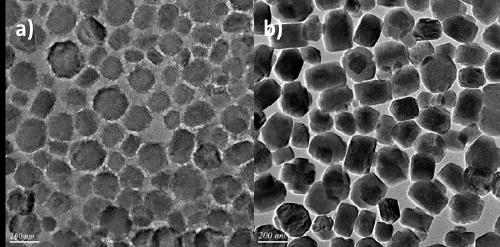

HZSM-5 molecular sieve with core-shell structure for methanol-to-aromatic hydrocarbon reaction and preparation method thereof

A ZSM-5, core-shell structure technology, applied in the field of methanol to aromatic hydrocarbon catalysis, can solve the problems of complex reactor structure, increase the reactor scale, waste of manpower and material resources, etc., to strengthen the reaction depth and coupling degree, improve catalytic performance, The effect of improving the response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Nucleosynthesis process

[0025] The aluminum source sodium metaaluminate (NaAlO 2 ) was dissolved in a certain amount of deionized water, the template agent tetrapropylammonium hydroxide (TPAOH) was added, and tetrapropylammonium hydroxide (TPAOH) was added dropwise with a peristaltic pump 2 Finally, a certain mass of metal species Zn was added, and after fully stirring evenly, aging was carried out in a water bath at 25 °C for 24 h. The final molar composition of each raw material was: 9 TPAOH: 25 SiO 2 : 400H 2 O: 0.42Al 2 o 3:0.12 Zn. Finally, transfer the uniformly stirred feed solution into a crystallization kettle, and rotate and crystallize at 80°C for 3 days, and finally put the obtained nuclear solution into a polytetrafluoroethylene bottle for later use.

[0026] (2) Shell construction process

[0027] A certain quality of aluminum sulfate (Al 2 SO 4 18H 2 O) dissolved in sodium hydroxide solution, then added silica sol for mixing, and finally ad...

Embodiment 2

[0031] (1) Nucleosynthesis process

[0032] The aluminum source sodium metaaluminate (NaAlO 2 ) was dissolved in a certain amount of deionized water, the template agent tetrapropylammonium hydroxide (TPAOH) was added, and tetrapropylammonium hydroxide (TPAOH) was added dropwise with a peristaltic pump 2 Finally, a certain mass of metal species Ga was added, and after fully stirring evenly, it was aged in a water bath at 50°C and stirred for 18 h. The final molar composition of each raw material was: 6TPAOH: 25 SiO 2 : 250H 2 O: 0.42Al 2 o 3 : 1.12 Ga. Finally, transfer the uniformly stirred material liquid into a crystallization kettle, rotate and crystallize at 120°C for 2 days, and finally put the obtained nuclear solution into a polytetrafluoroethylene bottle for later use.

[0033] (2) Shell construction process

[0034] A certain quality of aluminum sulfate (Al 2 SO 4 18H 2 O) Dissolved in sodium hydroxide solution, then added silica sol for mixing, and finally a...

Embodiment 3

[0038] (1) Nucleosynthesis process

[0039] The aluminum source sodium metaaluminate (NaAlO 2 ) was dissolved in a certain amount of deionized water, the template agent tetrapropylammonium hydroxide (TPAOH) was added, and tetrapropylammonium hydroxide (TPAOH) was added dropwise with a peristaltic pump 2 In the end, a certain amount of metal species Ga was added, and after stirring well, aging was carried out in a water bath for 50 o C under stirring for 36 h, the final molar composition of each raw material is: 6TPAOH: 25 SiO 2 : 1000H 2 O: 0.25 Al 2 o 3 : 0.67 Ga. Finally, transfer the uniformly stirred material liquid into a crystallization kettle, rotate and crystallize at 120°C for 2 days, and finally put the obtained nuclear solution into a polytetrafluoroethylene bottle for later use.

[0040] (2) Shell construction process

[0041] A certain quality of aluminum sulfate (Al 2 SO 4 18H 2 O) dissolved in sodium hydroxide solution, then added silica sol for mixing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com