Pre-lithiated negative plate, preparation method thereof and lithium battery

A negative electrode sheet, pre-lithiation technology, applied in its preparation method and lithium battery, the field of pre-lithiated negative electrode sheet, can solve the problems of unstable electronic pathway and inability to fully utilize the lithium-containing layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

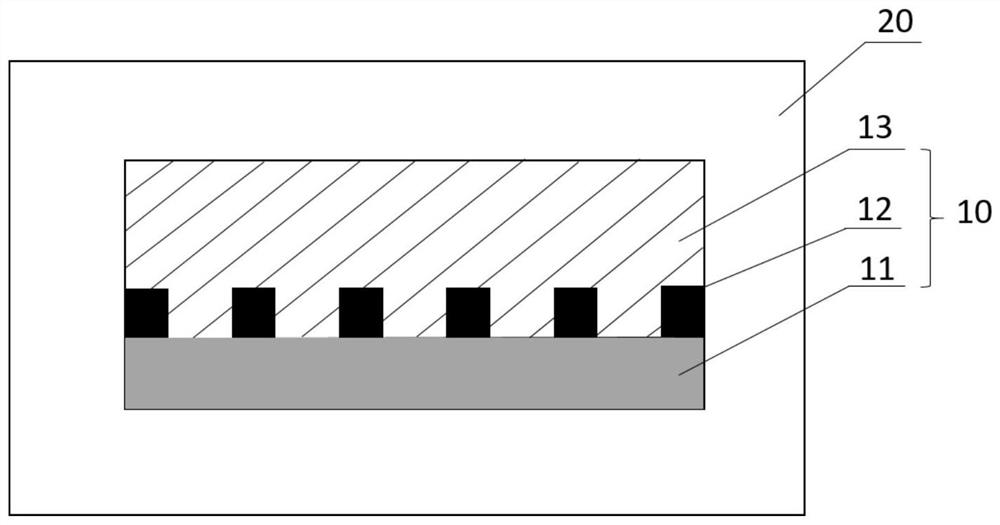

[0052] Preparation method of pre-lithiated negative electrode sheet

[0053] The embodiment of the second aspect of the present application provides a method for preparing the above-mentioned pre-lithiated negative electrode sheet, including the following steps:

[0054] (1) making lithium-ion battery negative pole, wherein, described lithium-ion battery negative pole comprises negative electrode current collector, and the active material layer that covers the surface of described negative electrode current collector;

[0055] (2) Depositing a plurality of modified layers at intervals on the surface of the negative electrode of the lithium ion battery, so that part of the surface of the active material layer covers the plurality of modified layers to obtain a negative electrode sheet of the lithium ion battery;

[0056] (3) Depositing a lithium-containing layer on the surface of the negative electrode sheet of the lithium-ion battery, covering the surface of the remaining pa...

Embodiment 1

[0072] This embodiment provides a pre-lithiated negative electrode sheet, its preparation method and lithium battery, comprising the following steps:

[0073] (1) Making the lithium-ion battery negative pole, wherein the lithium-ion battery negative pole includes a negative electrode current collector and an active material layer covering the surface of the negative electrode current collector.

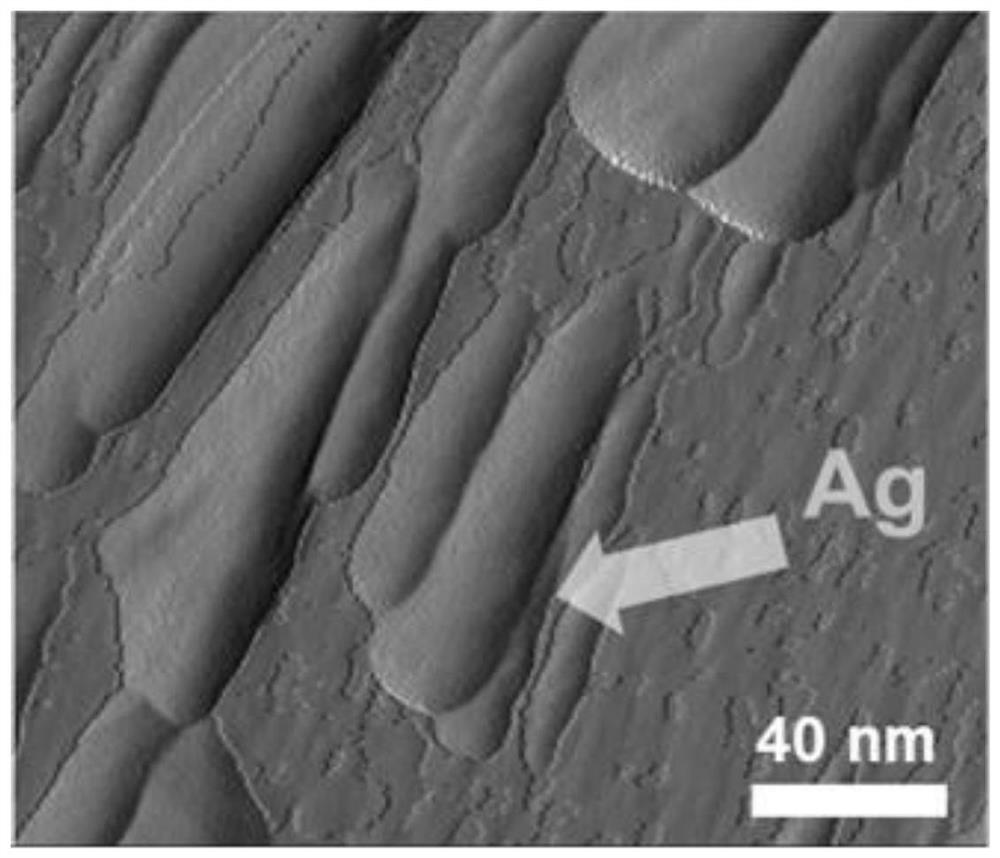

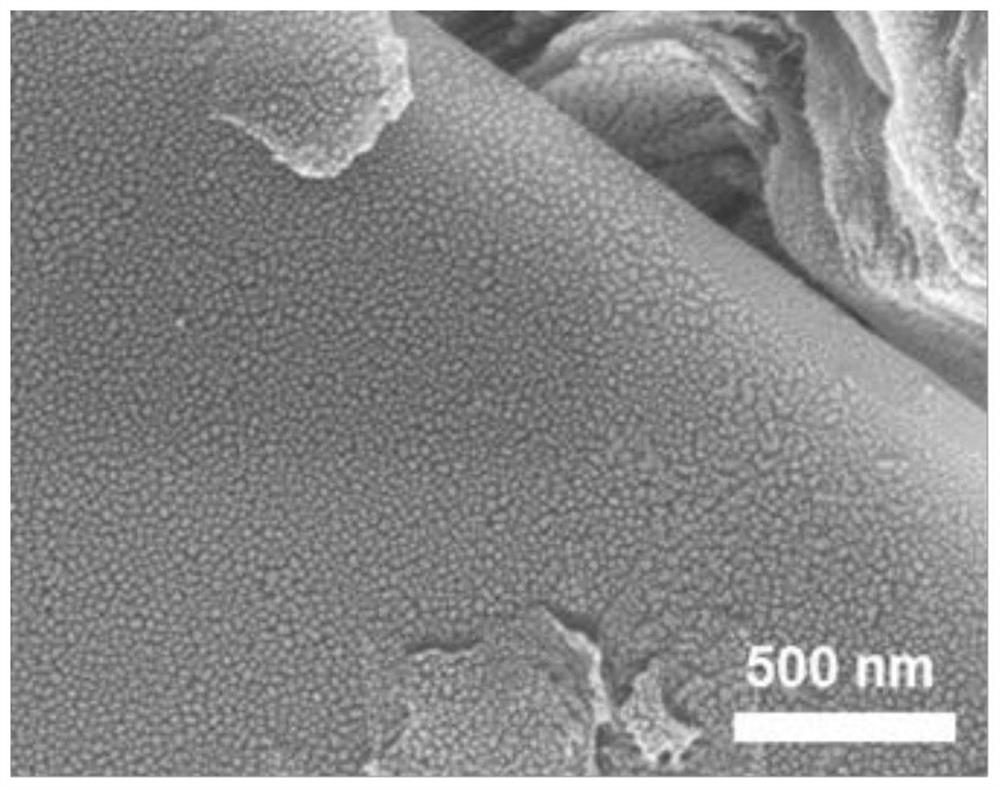

[0074] (2) by magnetron sputtering technology, on the surface of the negative pole described in step (1), deposit a layer of artificial electronic access layer, the material is metallic silver, and the mass per unit area of the artificial electronic access layer is 0.1% of the active material mass per unit area of the negative pole, The average area of a single modification layer in multiple modification layers is 2500nm 2 .

[0075] (3) Deposit a lithium-containing layer on the surface of the negative electrode described in step (2) by vacuum evaporation technology, which is l...

Embodiment 2

[0079] This embodiment provides a pre-lithiated negative electrode sheet, its preparation method and lithium battery, comprising the following steps:

[0080] (1) Making the lithium-ion battery negative pole, wherein the lithium-ion battery negative pole includes a negative electrode current collector and an active material layer covering the surface of the negative electrode current collector.

[0081] (2) by magnetron sputtering technology on the surface of the negative pole described in step (1), depositing a layer of artificial electronic access layer, the material is metallic silver, and the mass per unit area of the artificial electronic access layer is 0.5% of the active material mass per unit area of the negative pole, The average area of a single modification layer in multiple modification layers is 100nm 2 .

[0082](3) Deposit a lithium-containing layer on the surface of the negative electrode described in step (2) by vacuum evaporation technology, which is l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average area | aaaaa | aaaaa |

| Average area | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com