Method for processing full-range oil in coal tar

A processing method and full-fraction technology, applied in the field of coal chemical industry, can solve problems such as unreasonable diesel-steam ratio in the process, affecting the reaction severity of the fixed-bed refining section, and high toxicity, and achieve the effect of avoiding high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

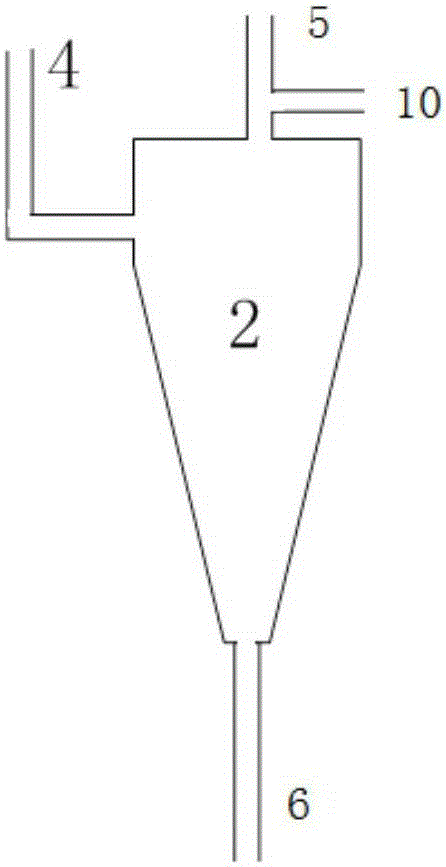

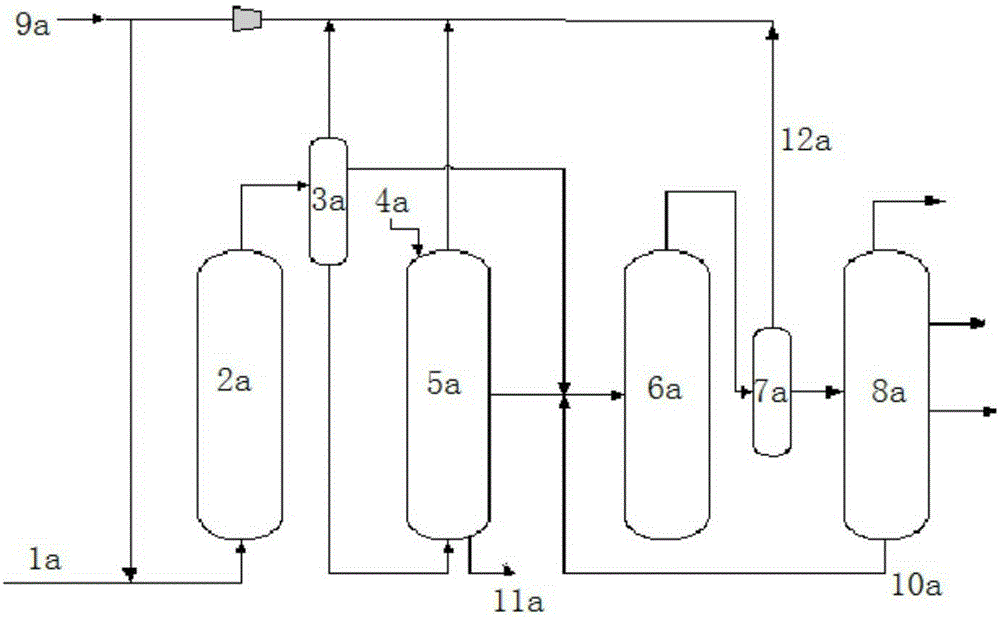

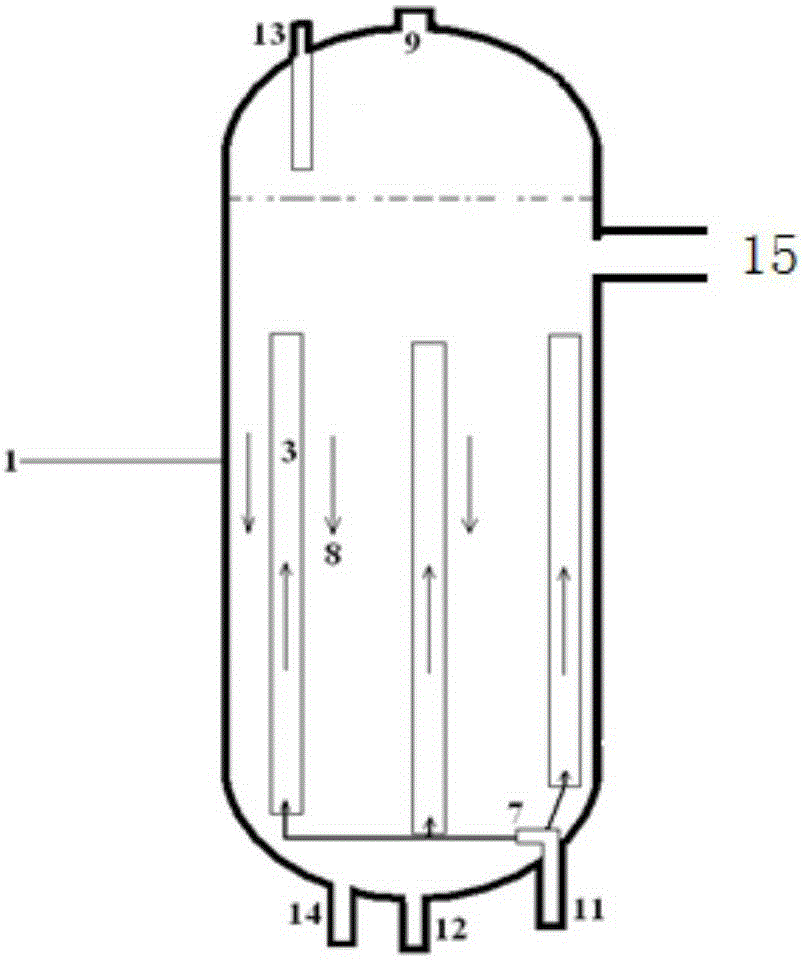

[0092] The secondary slurry bed reactor in Example 1 is a slurry bed reactor with an external hydrocyclone, and this embodiment uses figure 2 The process flow chart shown carries out the processing method of the whole distillate oil of coal tar. The specific operation method is as described in the above preferred specific embodiments of the present invention.

[0093] Moreover, the structure of the two-stage slurry bed reactor in this embodiment is as follows image 3 As shown in, the structure of the hydrocyclone in this embodiment is as follows figure 1 shown in . The structure of the first-stage slurry bed reactor in this embodiment is similar to that of the second-stage slurry bed reactor, the difference is that the first-stage slurry bed reactor does not contain a hydrocyclone. And the volume of the inner chamber of the first-stage slurry-bed reactor and the second-stage slurry-bed reactor is the same.

[0094] In this embodiment, the length of the sleeve is 3 / 5 of t...

Embodiment 2-4

[0101] Embodiment 2-4 adopts the technical process identical with embodiment 1 to carry out, and difference is that process condition is different, specifically, the relevant reaction conditions and the result in the one-stage slurry bed reactor of embodiment 2-4 are as table Shown in 2; Relevant reaction conditions and results in the two-stage slurry bed reactor are as shown in Table 3; Relevant reaction conditions and results of fixed-bed hydrotreating unit are as shown in Table 4, and product properties are shown in Table 5 .

[0102] Table 2

[0103]

[0104] table 3

[0105] Example 1 Example 2 Example 3 Example 4 Reaction conditions Pressure / MPa 16.0 16.0 18.0 18.0 temperature / ℃ 400 400 410 410 Liquid hourly volumetric space velocity / h -1

0.2 0.5 0.2 0.5 Hydrogen oil volume ratio 1000 1500 1000 1500 Reaction result / wt% second gas 1.73 1.38 1.96 1.55 low density phase 98...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com