Device and method for mineralizing low-concentration carbon dioxide by solid waste

A solid waste, carbon dioxide technology, applied in the removal of solid waste, chemical instruments and methods, transportation and packaging, etc., can solve the problems of reduced economic benefits, enhancement, and low strength of mineralized building materials, and achieve high cost savings and Corresponding energy consumption, ensuring product quality, and strengthening the effect of product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

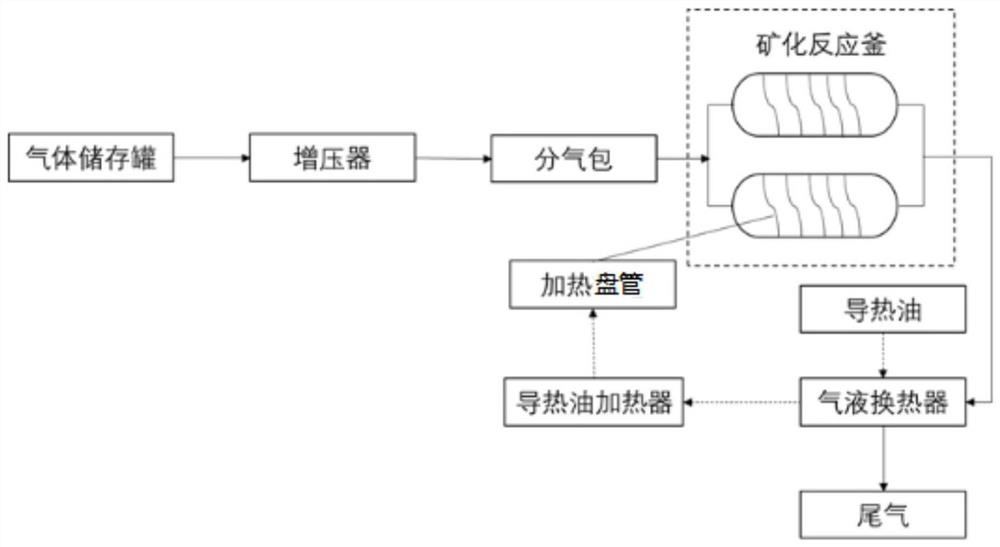

[0036] A device for mineralizing low-concentration carbon dioxide from solid waste, such as figure 1 , including successively connected gas storage tanks, boosters, gas distribution bags, multiple sets of mineralization reactors with heating coils and gas-liquid heat exchangers. Each group of mineralization reaction kettles includes two parallel and connected A kettles and B kettles, and a communication valve is provided between the connected mineralization reaction kettles to facilitate subsequent connection or closure of the communication of flue gas in the reaction kettles.

[0037] Among them, the outlet of the gas storage tank is connected with the inlet of the supercharger, and the outlet of the supercharger is connected with the inlet of the gas distribution bag for replenishing gas at any time. The gas inlet of the liquid heat exchanger is connected with the outlets of multiple groups of mineralization reaction kettles. The cold heat transfer oil enters the gas-liquid...

Embodiment 2

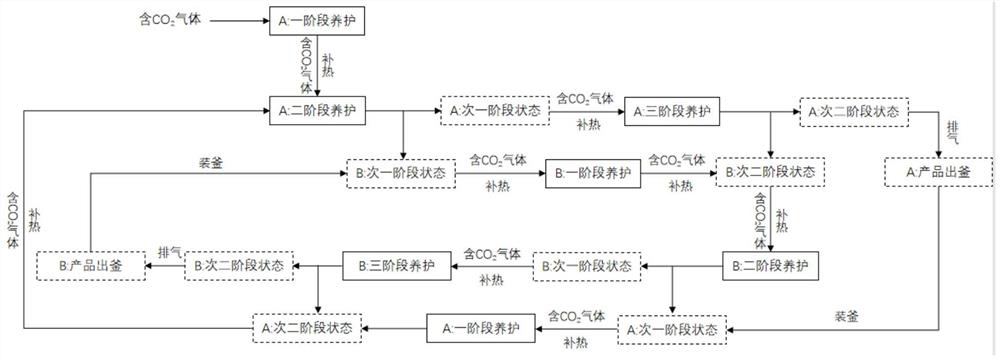

[0039] A method of mineralizing low-concentration carbon dioxide from solid waste, such as figure 2 ,details as follows:

[0040] (1) Place the compacted green body in the mineralization reaction kettle A and then close the reaction kettle, and fill the A kettle (i.e., the gas delivery kettle) with flue gas, wherein the flue gas includes 12.71mol% carbon dioxide and 75.88mol% nitrogen , 6.23mol% water vapor, 5.18mol% oxygen;

[0041] (2) One-stage curing: maintain the reaction temperature at 30°C, the reaction pressure at 0.3MPa, and cure for 1 hour; fill the green body into the B kettle (that is, the gas receiver) while reacting in the A kettle;

[0042] (3) Two-stage curing: continue to feed flue gas into kettle A, raise the temperature, maintain the reaction temperature at 60°C, and the reaction pressure at 1.2MPa, and cure for 1 hour;

[0043] (4) After the filling of the B kettle (gas receiving kettle) is completed, close the valve of the B kettle, and then connect wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com