Wastewater treatment catalytic ozonation reactor for fluidized bed and wastewater treatment method of wastewater treatment catalytic ozonation reactor

A technology of ozone catalytic oxidation and sewage treatment, applied in the direction of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of low sewage treatment efficiency, small specific surface area of catalyst, and affecting treatment effect, etc. Achieve the effects of improving ozone utilization rate and sewage treatment depth, improving mass transfer capacity and treatment effect, and avoiding channeling phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

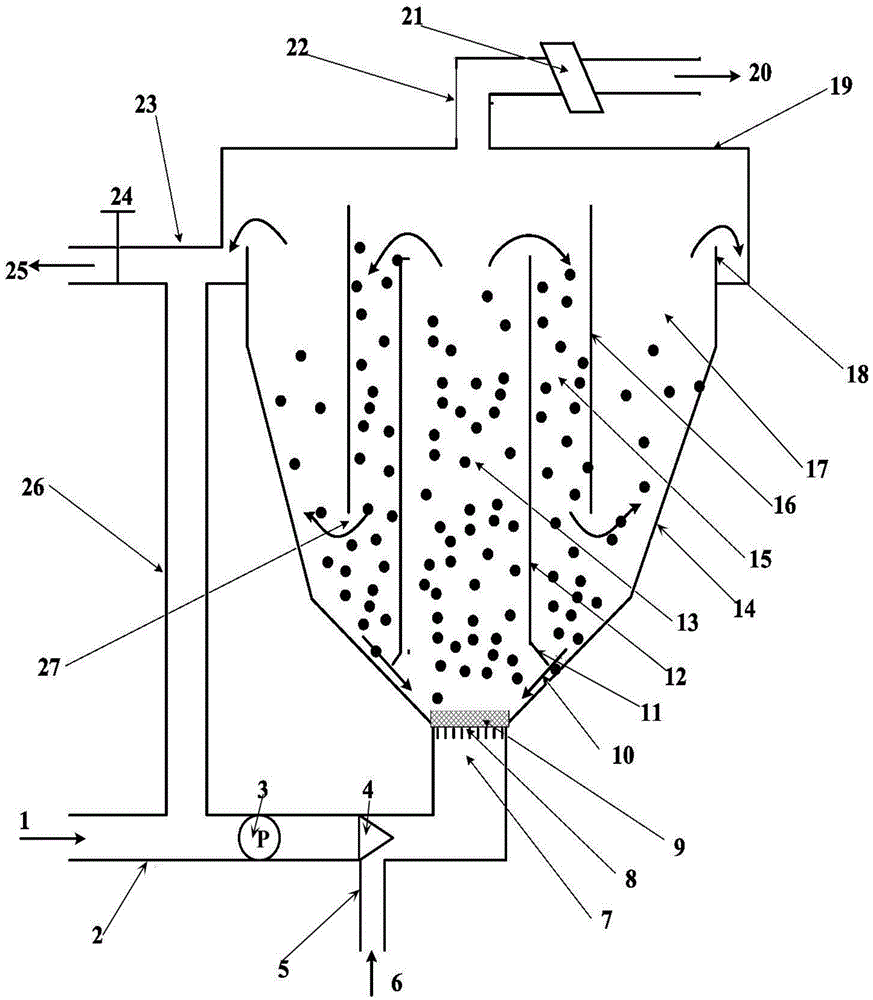

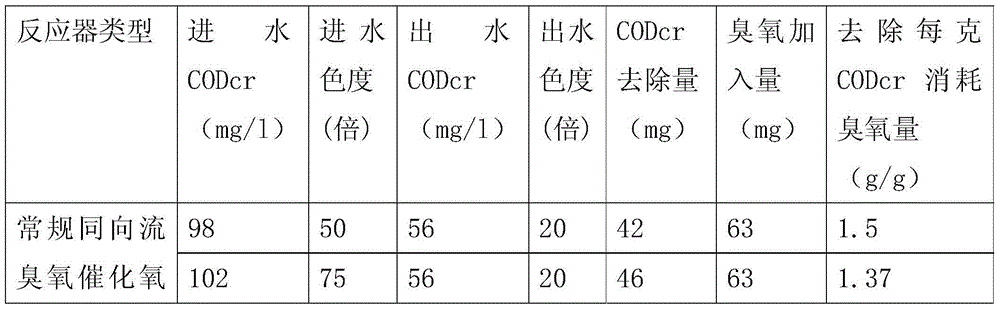

[0051] The effluent CODcr of the final sedimentation tank of sewage biochemical treatment in a printing and dyeing enterprise is about 100mg / l and the chroma is about 50. The enterprise requires that the CODcr is less than 60mg / l and the chroma is less than 20. For this reason, carried out this stock sewage ozone catalytic oxidation test, during the test, compared the fluidized bed ozone catalytic oxidation reactor provided by the present invention and conventional fixed bed catalytic oxidation reactor operation effect, the catalyst that two cover reactors are loaded Both are activated alumina-supported catalysts. The particle size of the catalyst loaded in the fluidized bed ozone catalytic oxidation reactor is 1.5-2.0mm, and the particle size of the catalyst loaded in the fixed-bed ozone catalytic oxidation reactor is 4.0-6.0mm. is 0.5 hours, and the operation results are shown in Table 1.

[0052] Table 1. Comparative test results of fluidized bed ozone catalytic oxidation r...

Embodiment 2

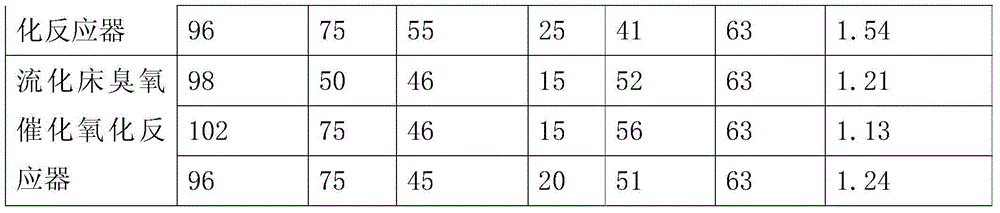

[0057] The CODcr of coking wastewater from a steel plant is about 100mg / l after biochemical treatment, and the enterprise requires that the CODcr of the discharged sewage is less than 60mg / l. To this end, the ozone catalytic oxidation test of this unit of sewage was carried out to verify whether the ozone catalytic oxidation process can achieve up-to-standard discharge. During the test, the fluidized bed ozone catalytic oxidation reactor provided by the present invention was compared with the conventional fixed bed catalytic oxidation reactor operation effect, and the catalysts loaded in the two sets of reactors were active alumina supported catalysts, and the fluidized bed ozone The particle size of the catalyst loaded in the catalytic oxidation reactor is 1.5-2.0mm, the particle size of the catalyst loaded in the fixed-bed ozone catalytic oxidation reactor is 4.0-6.0mm, the test scale is 0.5m3 / h, and the hydraulic retention time is 0.5 hours. See Table 2 for the running resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com