Combined crushing device

A crushing device and combined technology, which is applied in the field of combined crushing devices, can solve the problems of lack of automation, high efficiency and low cost, difficult dust control, low production efficiency, etc., to improve labor production efficiency, compact device structure, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

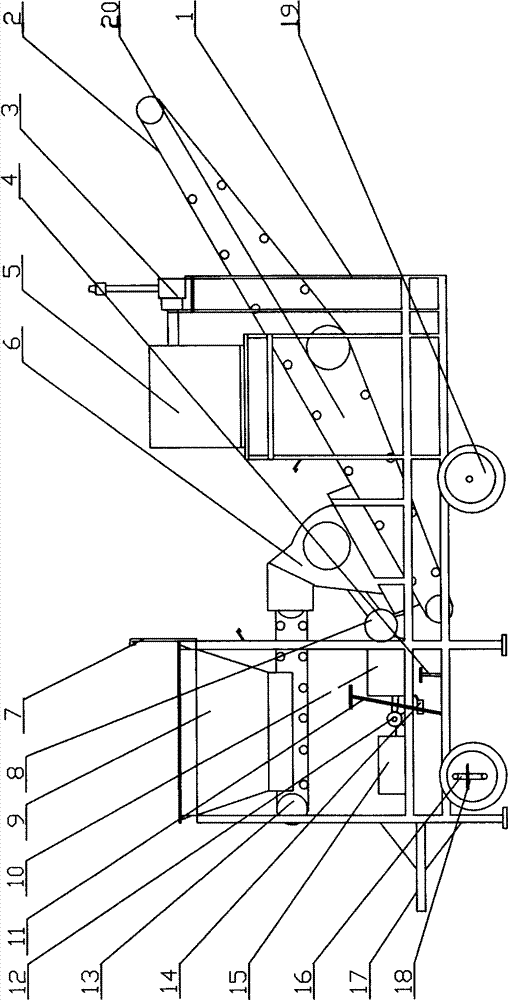

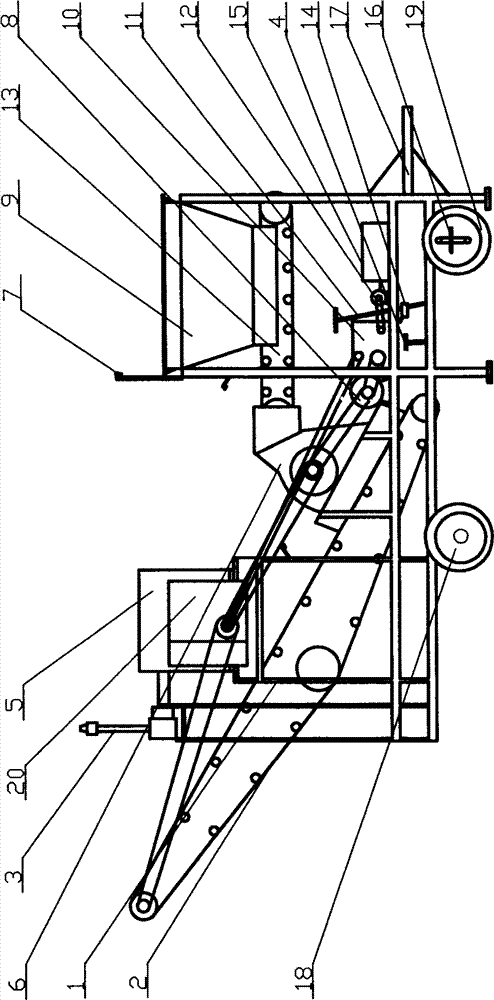

[0012] Such as figure 1 , figure 2 As shown, the combined pulverizing device mainly includes a steel bracket (1), a belt conveyor (2), a pulverizer (6), an electric motor (8), a funnel (9), a transmission clutch (10), a walking steering wheel (11), Water pump motor (12), feeder (13), internal combustion engine (20); Said symmetrical front wheels (18) and rear wheels (19) are respectively installed in the bottom of the section steel support (1), and front wheels (18) There is (16) that can make it go up and down; One side of the lower girder of the shaped steel support (1) is equipped with a walking steering wheel (11), a driver's seat stool (4), a walking brake (14), and a transmission clutch (10), Realize the walking of the crushing device; the rear wheel (19) and the feeder (13) are placed on the upper part of the section steel support (1) with the tractor (17), and the funnel (9) is above the feeder (13); the section steel support (1 ) on the upper girder belt tractor (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com