Metal wiring method based on mask print

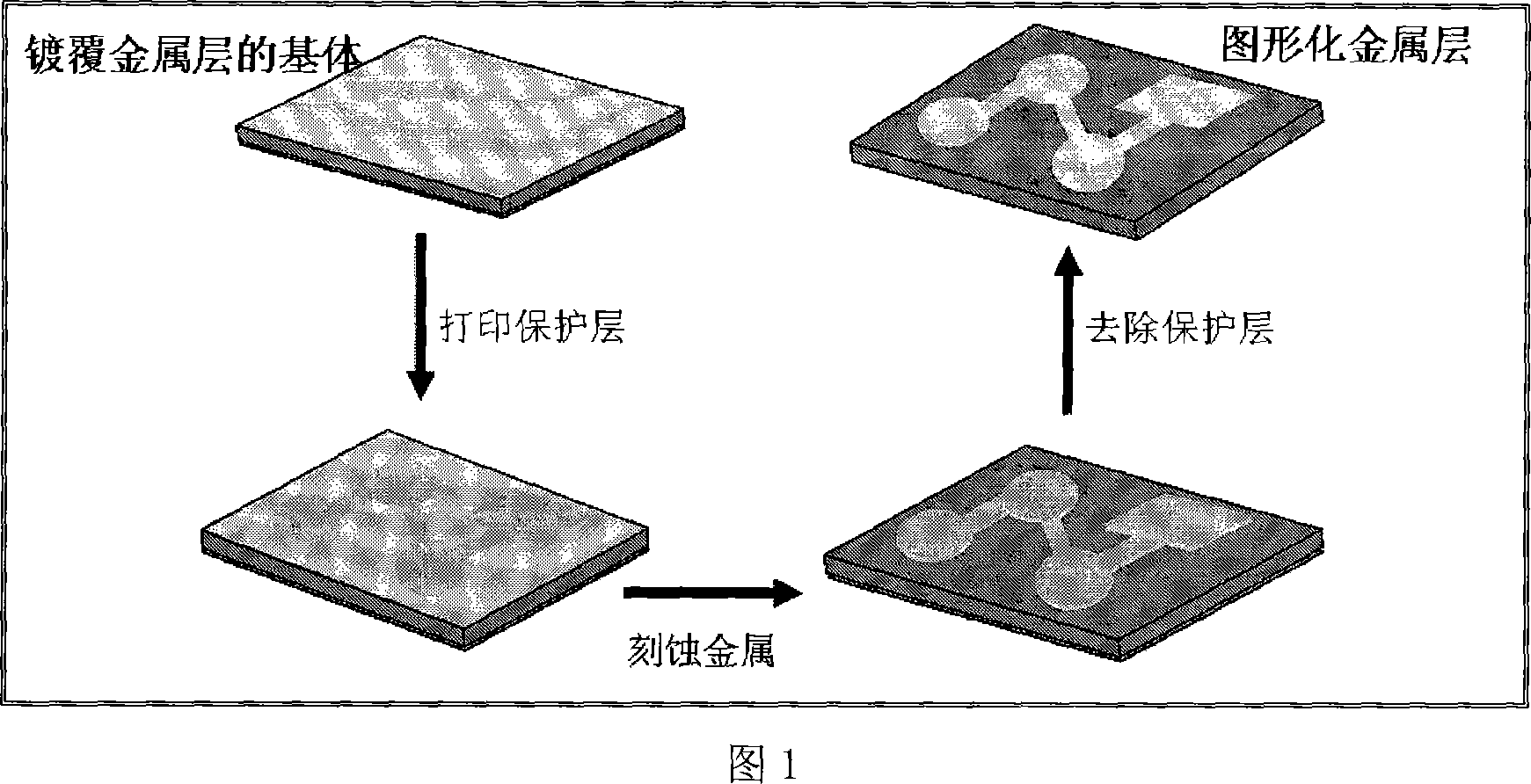

A metal wiring and mask technology, applied in the field of metal wiring based on mask printing, can solve the problems of poor metal deposition positioning selectivity, immature development of the full additive method, and difficult substrate processing, etc., and achieve uniform and stable body characteristics. Promotion, close effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

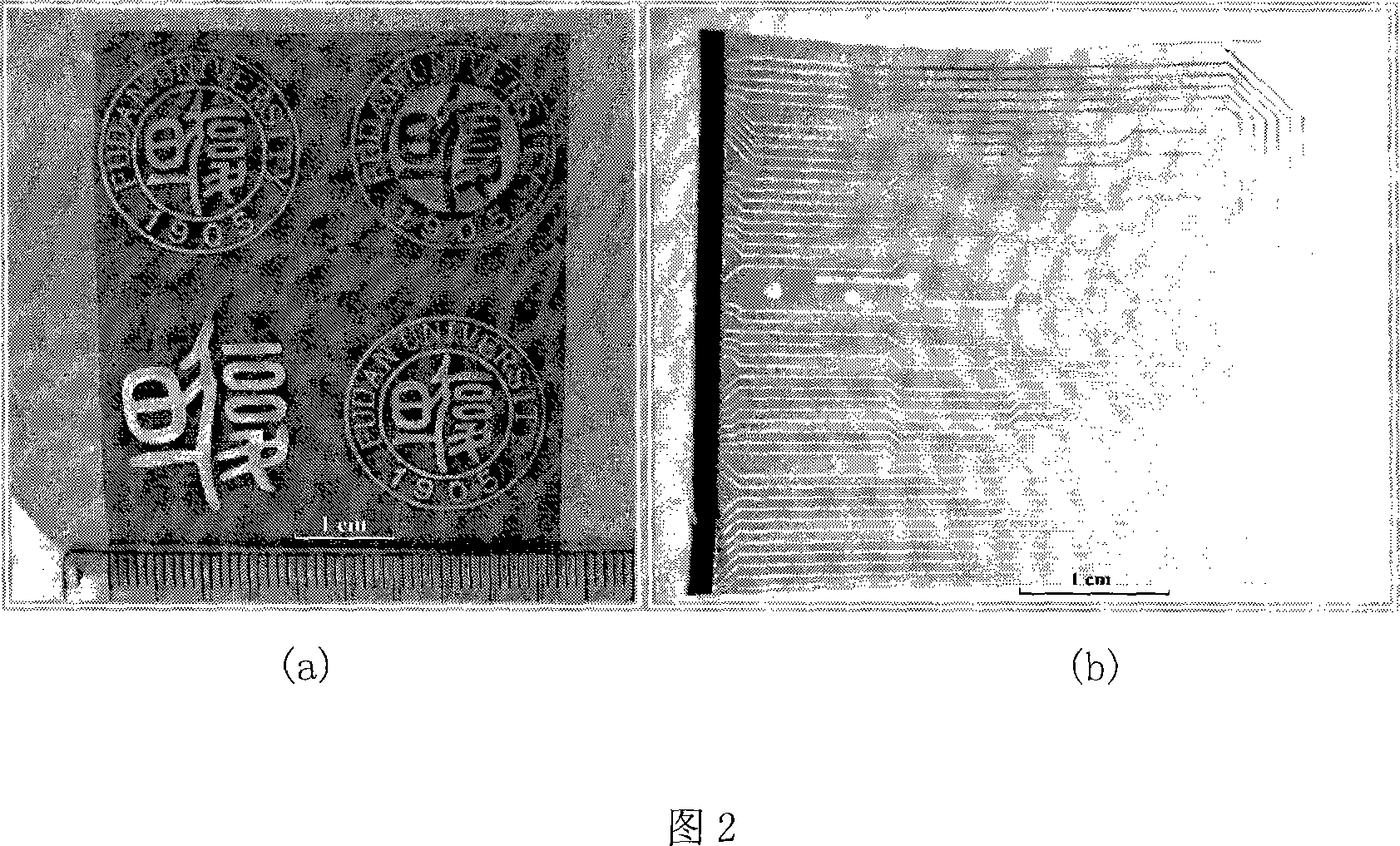

[0034] 1. PI resin surface processing copper circuit

[0035] Surface treatment: The PI resin substrate laminated with 50 micron copper foil is used as the substrate. First, use acetone to remove the copper surface grease, and then immerse it in dilute acid to remove the surface oxide layer. After rinsing with water, wipe the surface with a dry cloth for use.

[0036] Modifications to office printers: For HP laser printers, remove the toner cartridge and empty it before use. The mixed powder of thermosetting resin and activated carbon is used to replace the toner, and the mass ratio of the thermosetting resin powder is 10% to 90%. Install the toner cartridge, commission it, run the self-cleaning program, and remove excess toner.

[0037] Use Protel software to draw circuit graphics on the computer, and the toner flux is set to 10% to 100%. The paper type is "heavy paper", cancel the ink saving mode, adjust the fixed position of the PI resin sheet on the printing paper, print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com