Method for comprehensively using water and manganese slag in electrolytic manganese production

A technology for electrolysis of manganese and manganese slag, applied in the direction of electrolysis process, electrolysis components, improvement of process efficiency, etc., can solve the problems of high equipment investment and concentration cost, difficult industrial implementation, no economic benefits, etc., and achieve high economic and environmental benefits. , The effect of less fixed investment and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

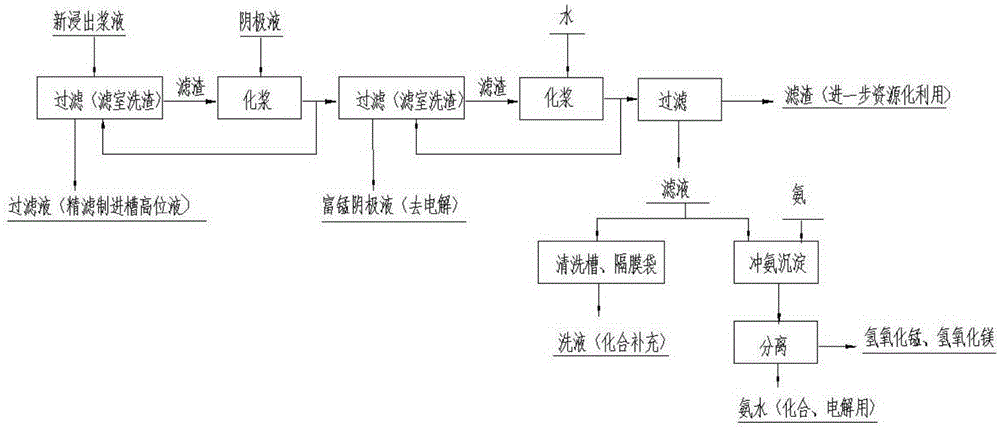

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments, a method for comprehensive utilization of electrolytic manganese production water and manganese slag, specifically comprising the following steps:

[0022] ① Catholyte replacement, coarse filtration of the new leaching slurry, and fine filtration of the coarse filtrate for electrolysis, and the manganese slag cake in the coarse filtration contains Mn 2+ 36g / L, use the cathode liquefaction slurry of the electrolytic cell, the mass ratio of slag to liquid is 1:1, 10 tons of wet slag will be produced according to 1 ton of electrolytic manganese, and 10 tons of catholyte will be consumed. After the slurry is filtered, the catholyte will contain Mn 2+ From the original 14g / L to 18 / L, it can be directly used for electrolysis; the filter cake contains 25% liquid, and the liquid contains Mn 2+ From the original 36 / L to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com