High performance mirror polish equipment with double grinding heads and technique method of mirror polish

A technology of mirror polishing and double grinding heads, which is applied in the direction of grinding/polishing equipment, grinding machines, manufacturing tools, etc. It can solve the problems of electrolyte pollution of workpieces and operating environment, troublesome post-processing of workpieces, and many times of transfer, so as to improve reliability. Implementability and practicability, reduced tool cost, easy replacement and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

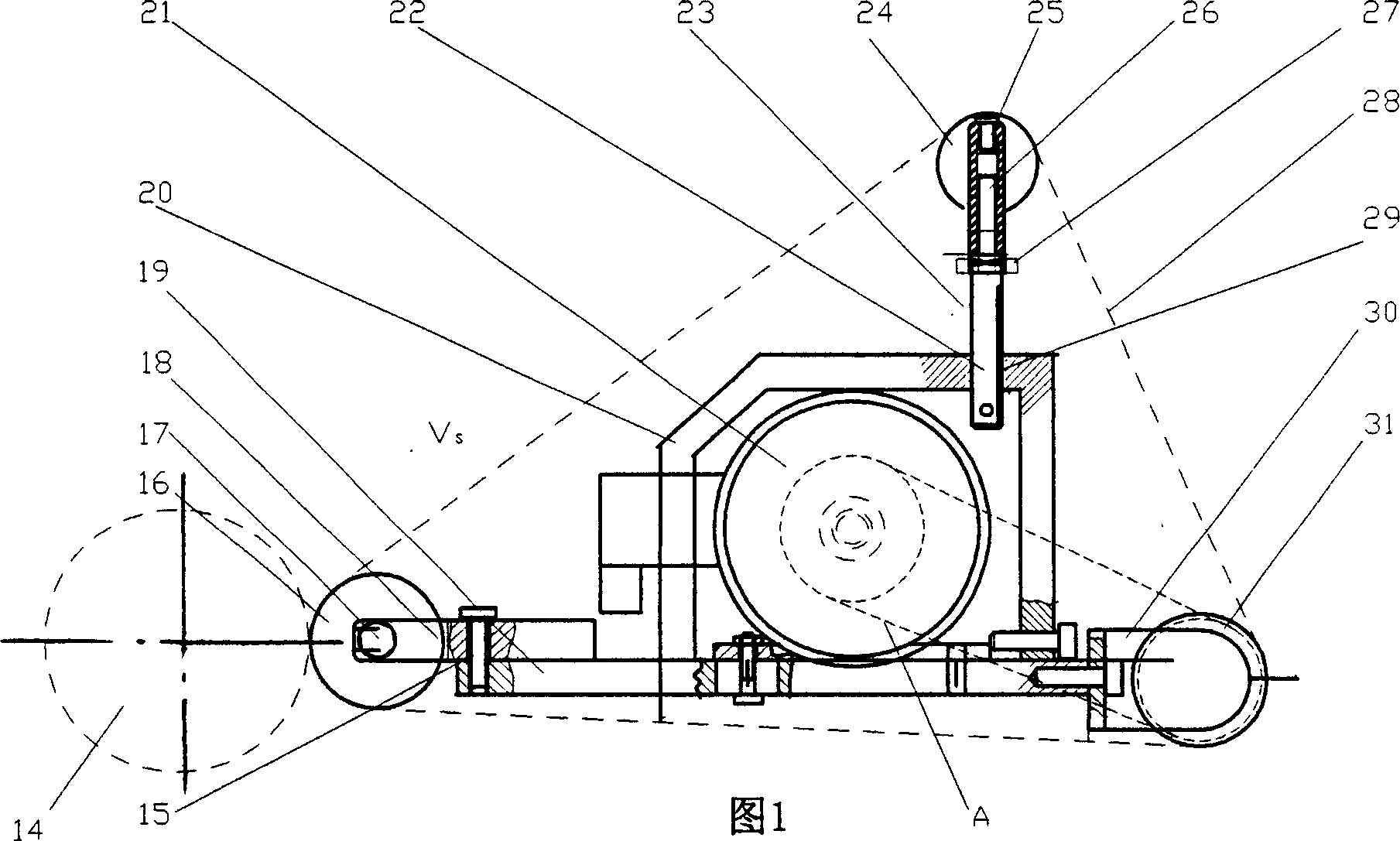

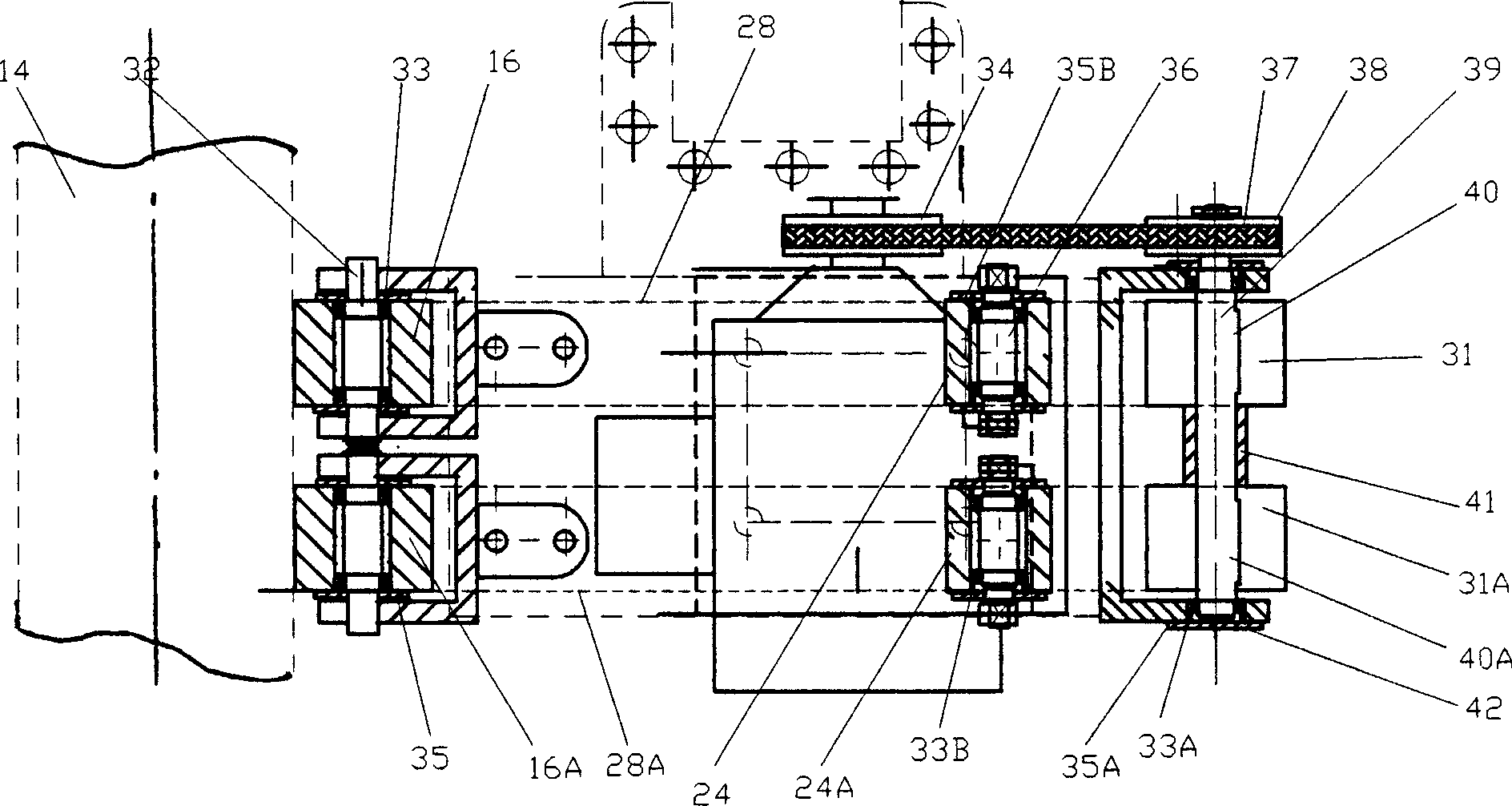

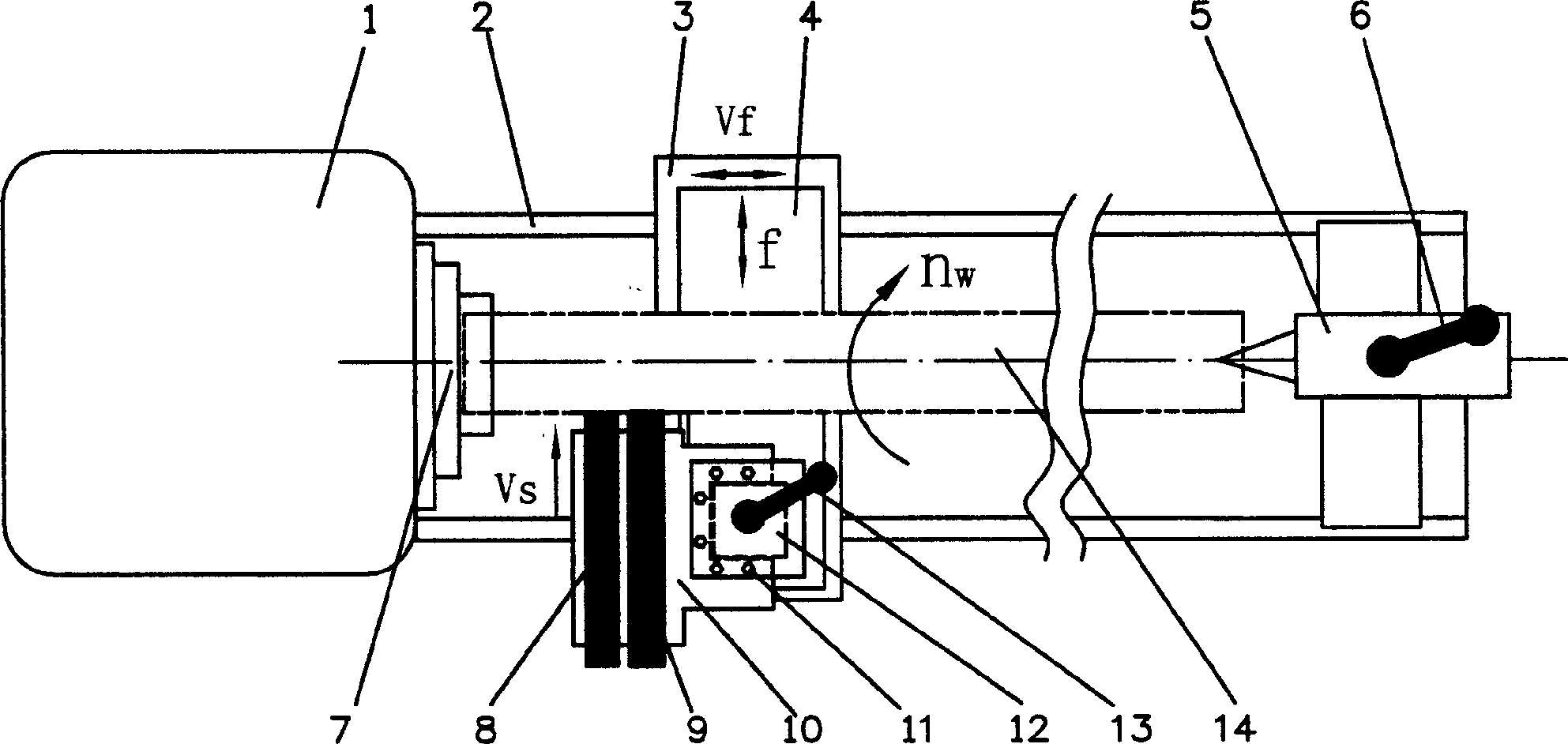

[0040]Structural schematic diagram of the present invention as shown in Figure 1, 2, comprises contact wheel (16,16A), tension pulley (24,24A), abrasive belt (28,28A), driving wheel (31,31A), contact axle (32), tensioner shaft (36), drive shaft (39), motor (21) and transmission mechanism A thereof, the driving part of transmission mechanism A is connected with the output shaft of motor (21), and the driven part of transmission mechanism A Connected with the drive shaft (39), the drive wheels (31, 31A) are installed on the drive shaft (39) through keys (40, 40A) respectively, and the drive wheels (31, 31A) are respectively driven by abrasive belts (28, 28A) Give the contact wheel (16,16A) that is sleeved on the contact wheel shaft (32) and the tensioning wheel (24,24A) that is sleeved on the tensioning wheel shaft (36).

[0041] In order to make the present invention compact in structure and obtain a longer abrasive belt perimeter, the present invention adopts a triangular layo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com