Process and device for treating copper-lead smelting mixed slag through bottom-blowing bath smelting technology

The invention relates to a molten pool smelting and technical treatment technology, which is applied to the process and the field of the device for treating mixed slag of copper and lead smelting by using the bottom blowing molten pool smelting technology, and can solve the problems of strong corrosiveness of slag, difficult recovery of flue gas, high labor intensity, etc. problem, to achieve the effect of low labor intensity, reduced production cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

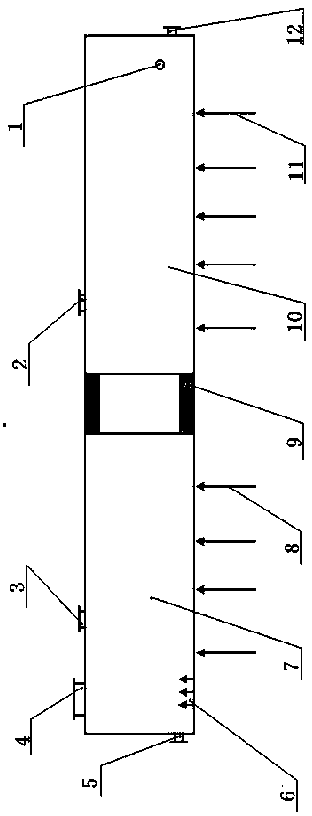

[0037] like figure 1 As shown, the copper-lead smelting mixed slag is used as the main material. If the molar ratio between the amount of S and the amount of Cu in the copper-lead smelting mixed slag is less than 2:1, sulfur-containing materials must be added to the auxiliary materials so that the amount of S and Cu The quantity molar ratio is not less than 2:1, and the sulfur-containing material is lead sulfide ore or copper sulfide ore. Add iron powder, quartz and pebbles or quicklime to the copper-lead smelting mixed slag. The amount of iron powder, quartz and pebbles or quicklime is determined according to the test data of iron, silicon and calcium in the copper-lead smelting mixed slag to ensure that the FeO in the output slag is / SiO 2 The weight ratio is between 0.8~1.2, CaO / SiO 2 The weight ratio is between 0.4~0.8, and then it is fed into the furnace from the feeding port 2 of the smelting zone 10, and injected into the furnace through the spray gun 11 at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com