Method for preparing ferric oxide yellow pigment by waste iron hydrochloric acid lotion

A technology of iron oxide yellow and hydrochloric pickling, which is applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., to achieve accelerated oxidation rate, low material cost and energy consumption cost, and improved tinting strength and adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

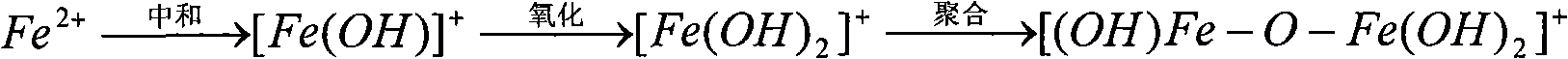

Method used

Image

Examples

Embodiment 1

[0026] Take 20mL of waste iron hydrochloric acid solution (pH is -1.12, iron content 50g / L, hereinafter referred to as the raw material solution) from the iron and steel plant, stir, filter, and adjust the pH to 2.5 with caustic soda solution, the raw material solution changes from golden yellow to light yellow slightly With brown color, let it stand for 1 hour to obtain the treated raw material solution without precipitation or suspension generation;

[0027] The treated raw material solution was transferred into a 250mL three-necked flask, and 7.2mL of 25% ammonia water was added to neutralize the strong acidity and further generate a dark blue precipitate with a pH of 7.68. Stir and control the temperature to 25°C, add 0.12mL of 5% sodium hypochlorite solution with mass concentration, and flow air with a flow rate of 0.5L / min from the bottom to ensure full contact of the gas-liquid-solid three-phase in the entire reactor. As the reaction progresses, the pH value of the syst...

Embodiment 2

[0032] Take 20mL of waste iron hydrochloric acid solution (pH is -1.22, iron content 40g / L) from the machinery manufacturing industry, stir, filter, adjust the pH to 2.8 with ammonia water, the raw material solution changes from golden yellow to light yellow and slightly brown, and let it stand After 1 hour, the treated raw material solution was obtained without precipitation or suspended solids;

[0033] Transfer the treated raw material solution into a 250mL three-necked flask, add 8mL 25% ammonia water to neutralize the strong acidity and further generate a dark blue precipitate, the pH is 7.39, stir and control the temperature to 20°C, add 0.12mL mass concentration 5 % sodium hypochlorite solution. Air with a flow rate of 0.4 L / min was introduced from the bottom. As the reaction progressed, the pH value of the system gradually decreased. When more solid slurry was formed and stirring was difficult, add 15 mL of distilled water. When the pH of the reaction system is 5.5, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com