Recovering device for oxidization low pressure end gas in process of preparing terephthalic acid

A technology for recovering terephthalic acid and tail gas, which is applied in the fields of organic chemistry, carboxylate preparation, carboxylate preparation, etc., can solve the problems of unreliable running state of tail gas compressor system, large liquid entrainment, and inability to cool, etc. Achieve significant economic benefits, improved recycling rate, and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention aims at the defects of the low-pressure tail gas recovery device in the oxidation stage of the terephthalic acid production in the prior art, abandons the complex and unreliable tail gas compressor system, and completely solves the serious failure of the compressor caused by a large amount of liquid entrainment into the compressor and cannot operate normally To solve the problem, the PX and methyl acetate in the tail gas can be effectively recovered, and the unit consumption of raw materials of the whole device can be reduced.

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

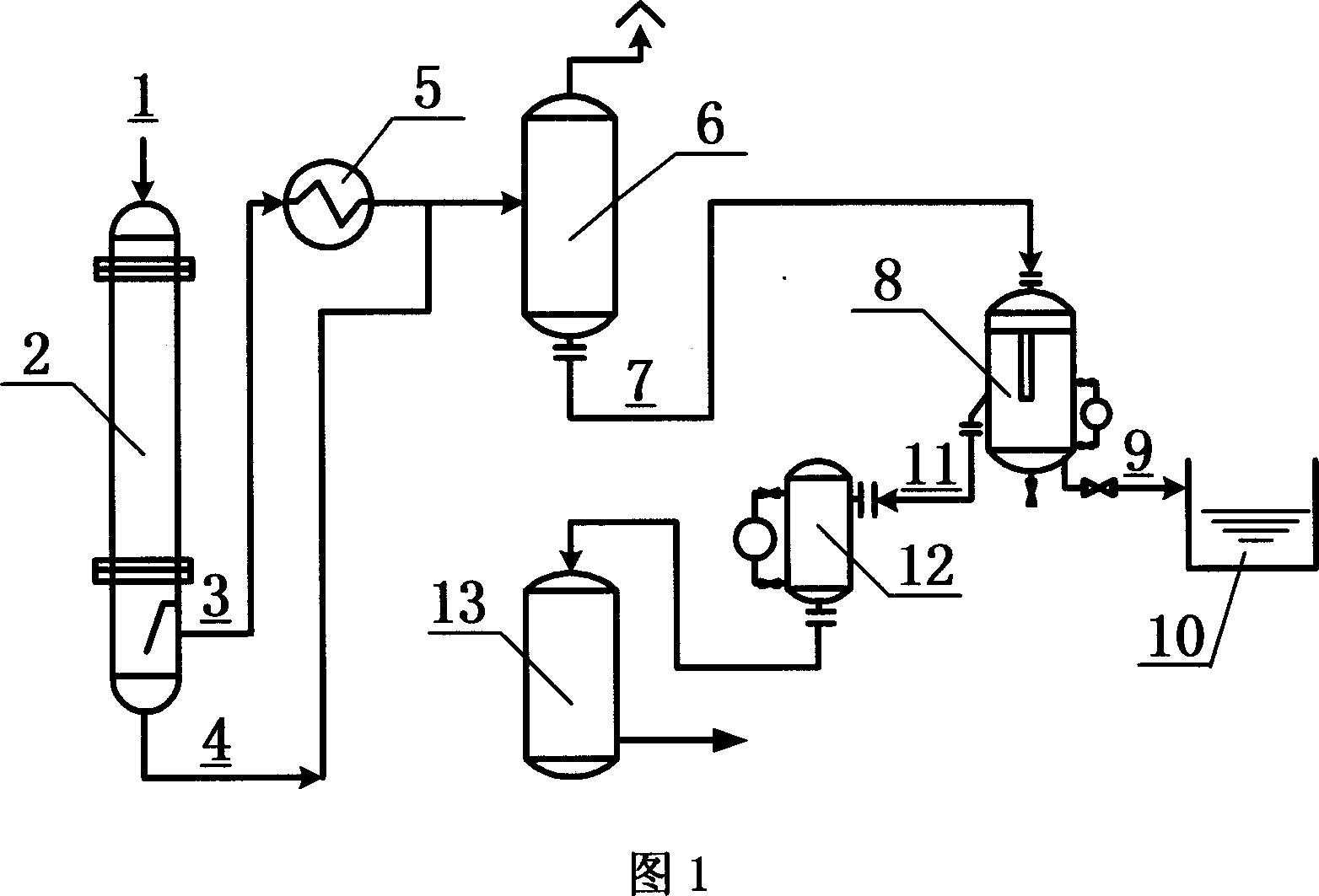

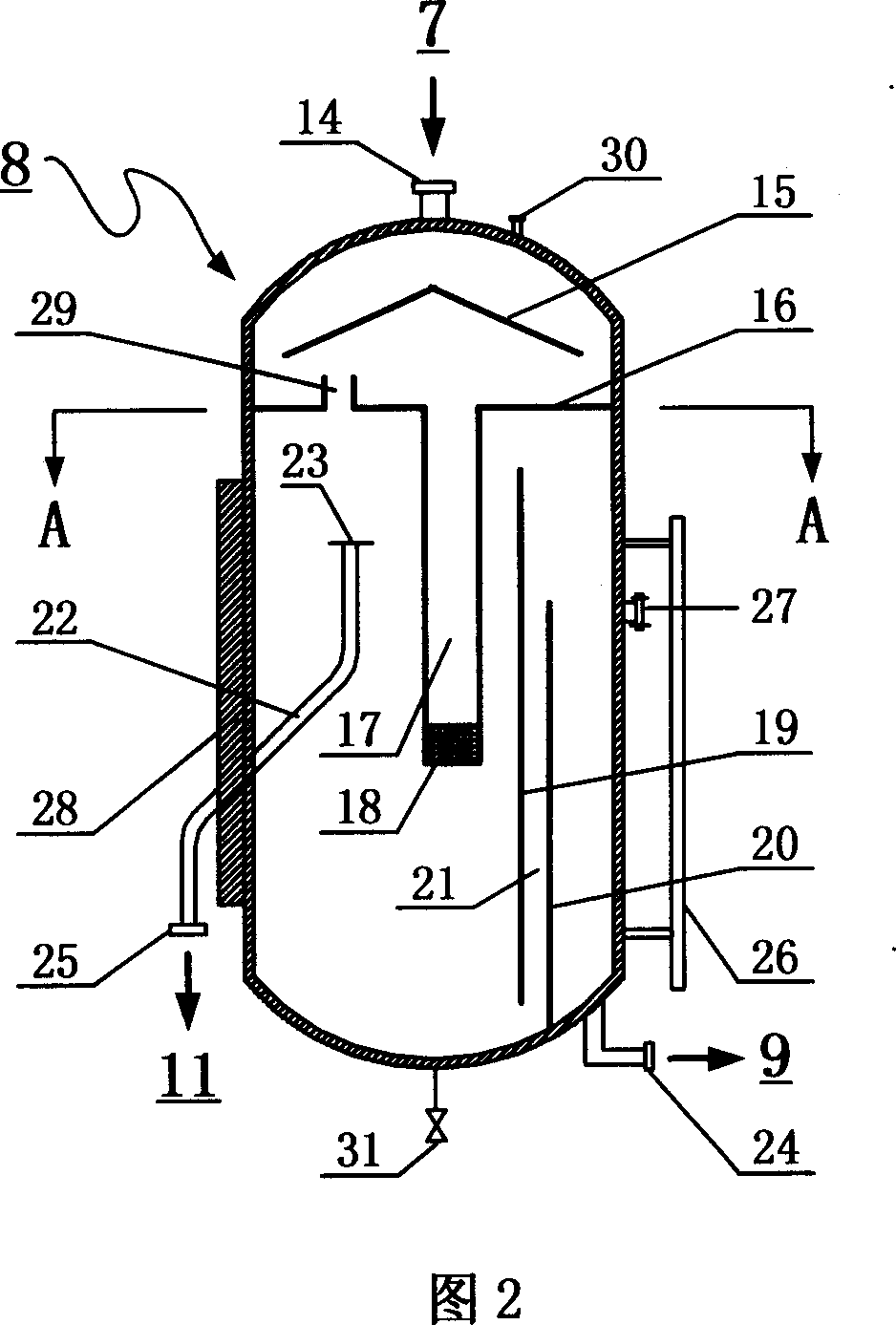

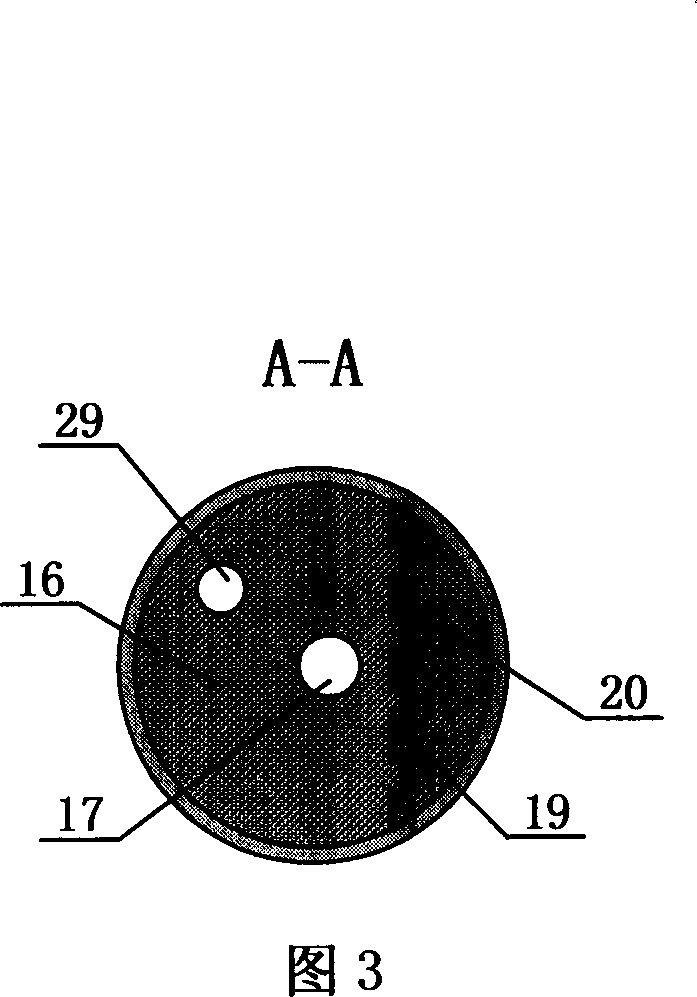

[0020] As shown in Figure 1, in the oxidation low-pressure tail gas recovery device in the production of terephthalic acid, the low-pressure tail gas 1 from the condensing tank of the acetic acid dehydration tower in the oxidation stage of terephthalic acid production enters the high-efficiency cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com