Oil field associated gas ethane recovery system

A technology of oilfield associated gas and recovery system, which is applied in the field of oilfield associated gas ethane recovery system, and can solve the problems of large energy loss and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

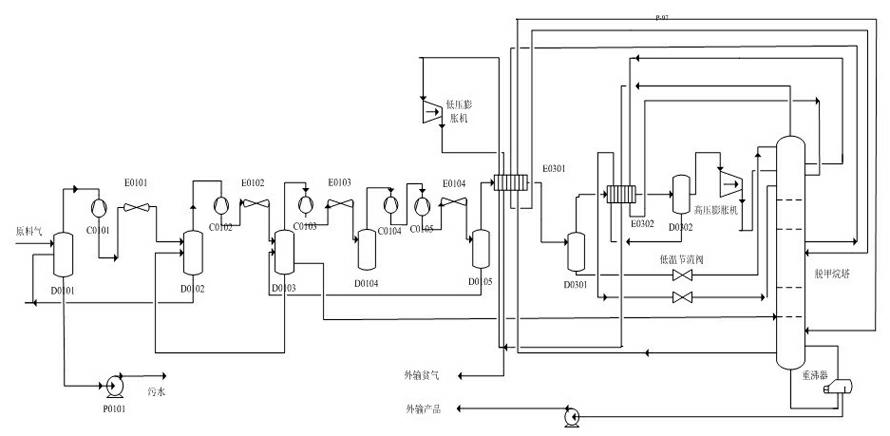

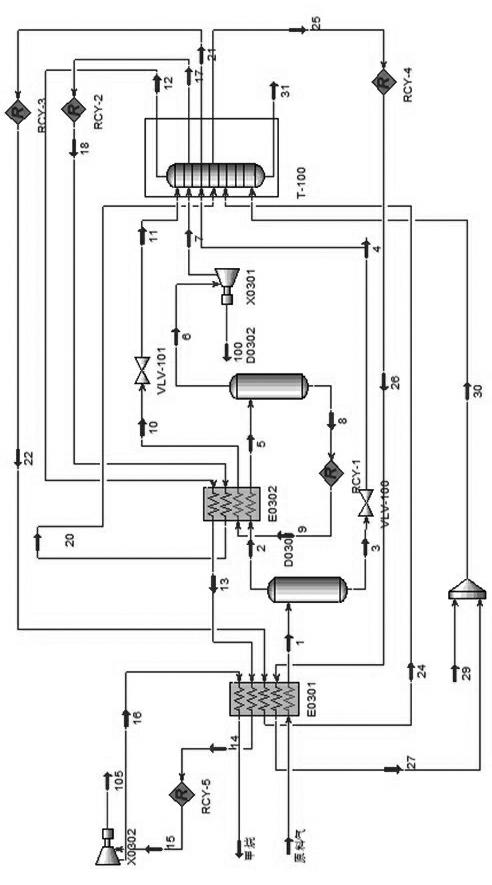

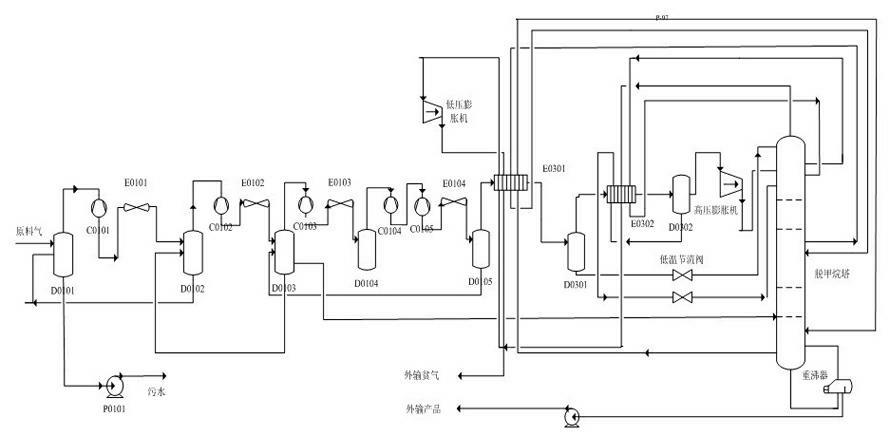

[0030] Oilfield associated gas ethane recovery system, including: feed gas pressurization unit, feed gas dehydration unit and low temperature fractionation unit, such as figure 1 as shown,

[0031] 1) Raw material gas pressurization unit: including five-stage centrifugal compressors, there is an air cooler between each two-stage centrifugal compressor, the raw material gas enters the raw material separator D0101 at 15.6°C, 0.15MPa, 69.3Kgmole / h, and removes the gas The water and other impurities brought in. After the raw material gas comes out of D0101, it enters five-stage centrifugal compressors respectively: C0101, C0102, C0103, C0104, and C0105 are pressurized in five stages, and the final pressure reaches 5.1MPa. The pressurized gas of each stage is cooled by air coolers E0101~E0104 respectively. The temperature of the gas coming out of each stage of air cooler is 38°C. The condensate in the gas is separated in D0102, D0103, D0104 and D0105 respectively. The liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com