Method for reclaiming ethylene in catalytic dry gas

A dry gas and ethylene technology, applied in chemical instruments and methods, liquefaction, organic chemistry, etc., can solve the problems of high energy consumption, large investment and large equipment scale, and achieve the effect of low energy consumption, less investment and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

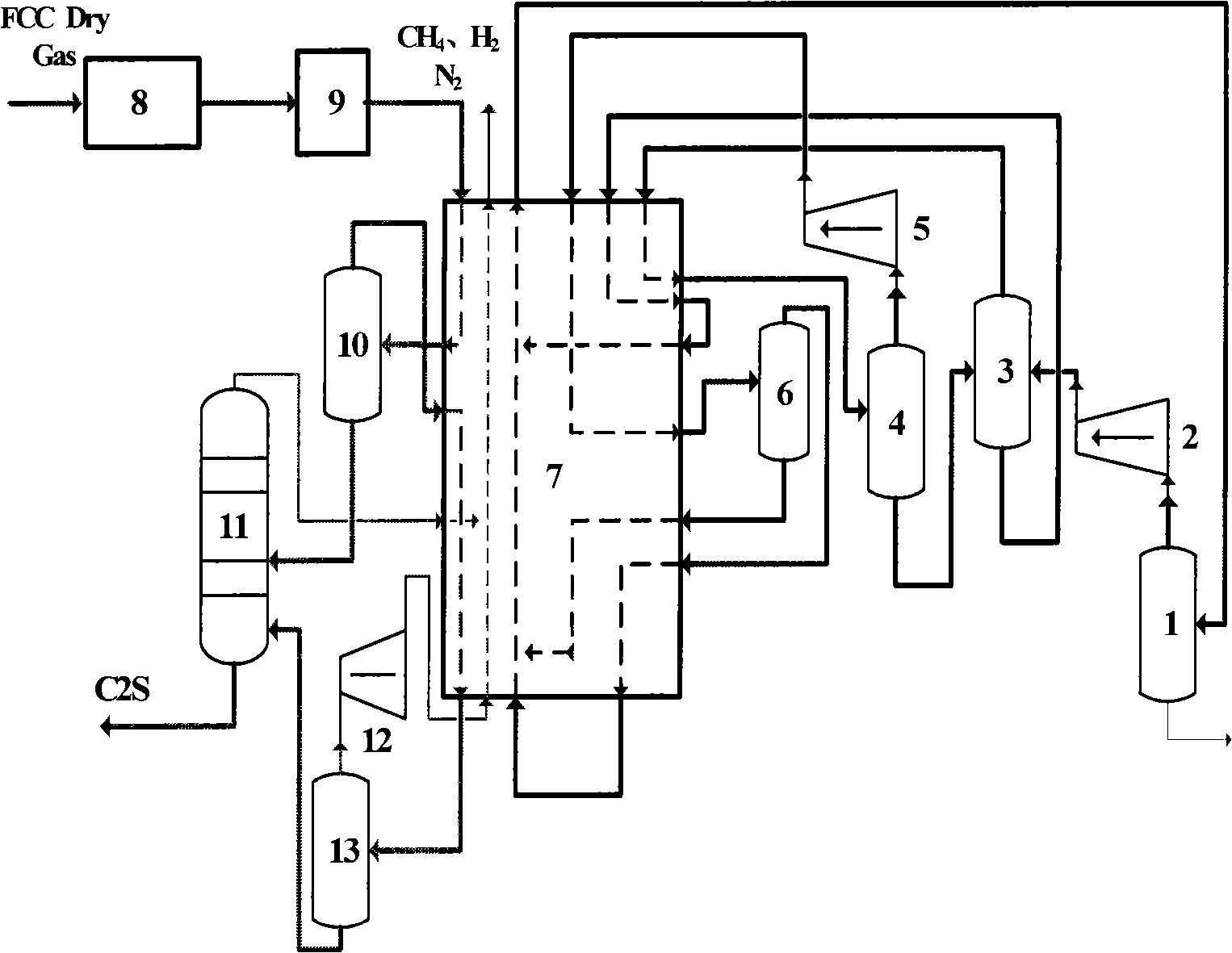

[0032] This embodiment further explains the method of the present invention by taking the recovery of ethylene from a refinery catalytic dry gas as an example, and the composition of the catalytic dry gas is listed in Table 1.

[0033] Table 1 Composition of catalytic dry gas in a refinery

[0034]

[0035] (1) Catalytic dry gas cooling: The catalytic dry gas with a flow rate of 13504 kg / h passes through the purification system 8 and the dryer 9 to remove carbon dioxide, oxygen, NOx and water, and then enters the cold box 7 . After the catalytic dry gas is cryogenically cooled to -105°C, it enters the heavy hydrocarbon separation tank 10 . The gaseous phase with a mass flow rate of 7495kg / h at the top of the tank enters the cold box 7 again to continue deep cooling, and the liquid phase at the bottom of the tank with a mass flow rate of 5003kg / h is directly sent to the methane tower 11. The temperature of the gas phase after being cryogenically cooled again is -142°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com