Preparing method of isobutene using tert-butyl alcohol

A technology for tert-butanol and isobutene, which is applied in the field of high-purity isobutene by dehydration of tert-butanol, can solve the problems of high energy consumption and high equipment investment, and achieves the effects of less equipment investment, easy operation and convenient filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

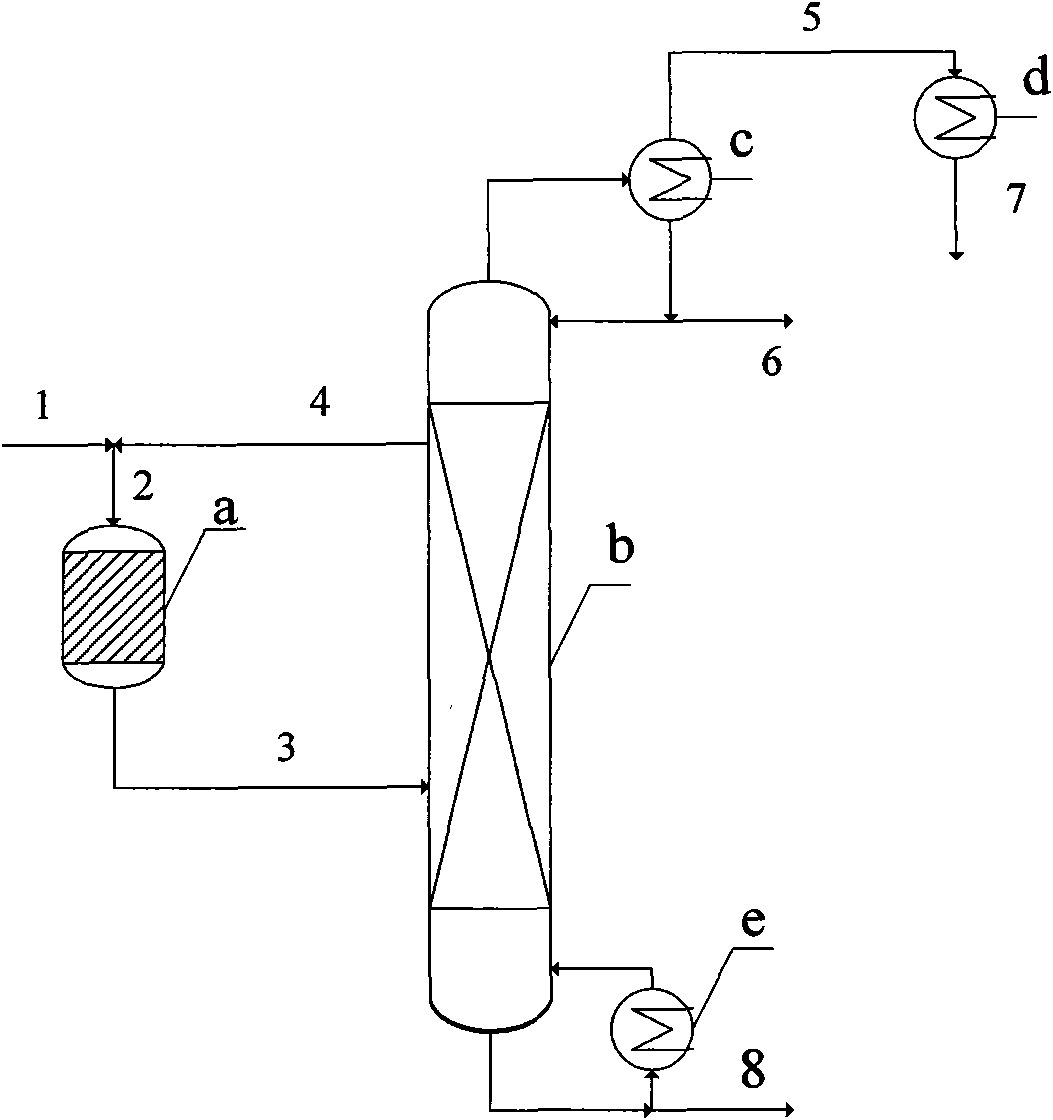

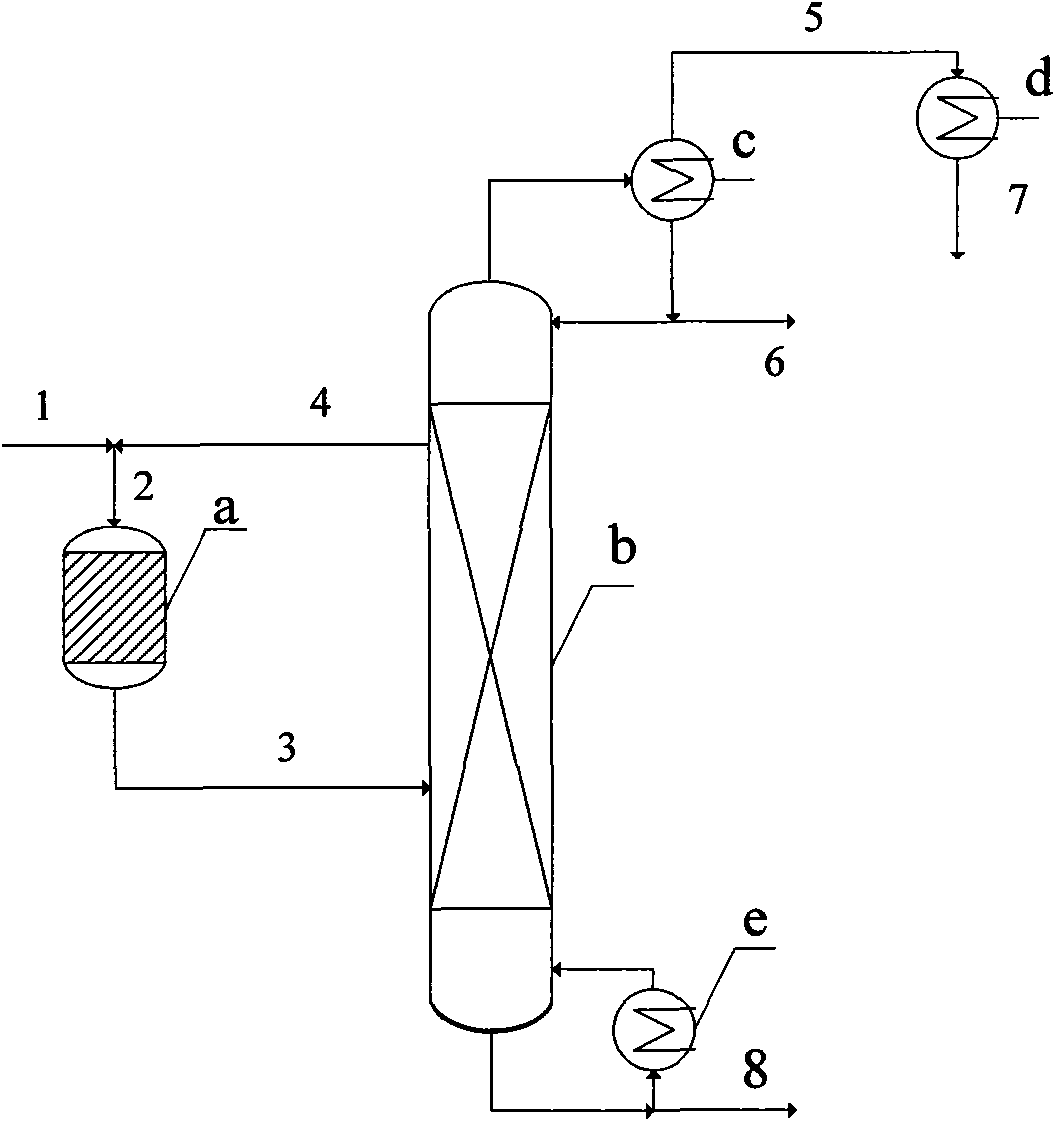

Embodiment 1

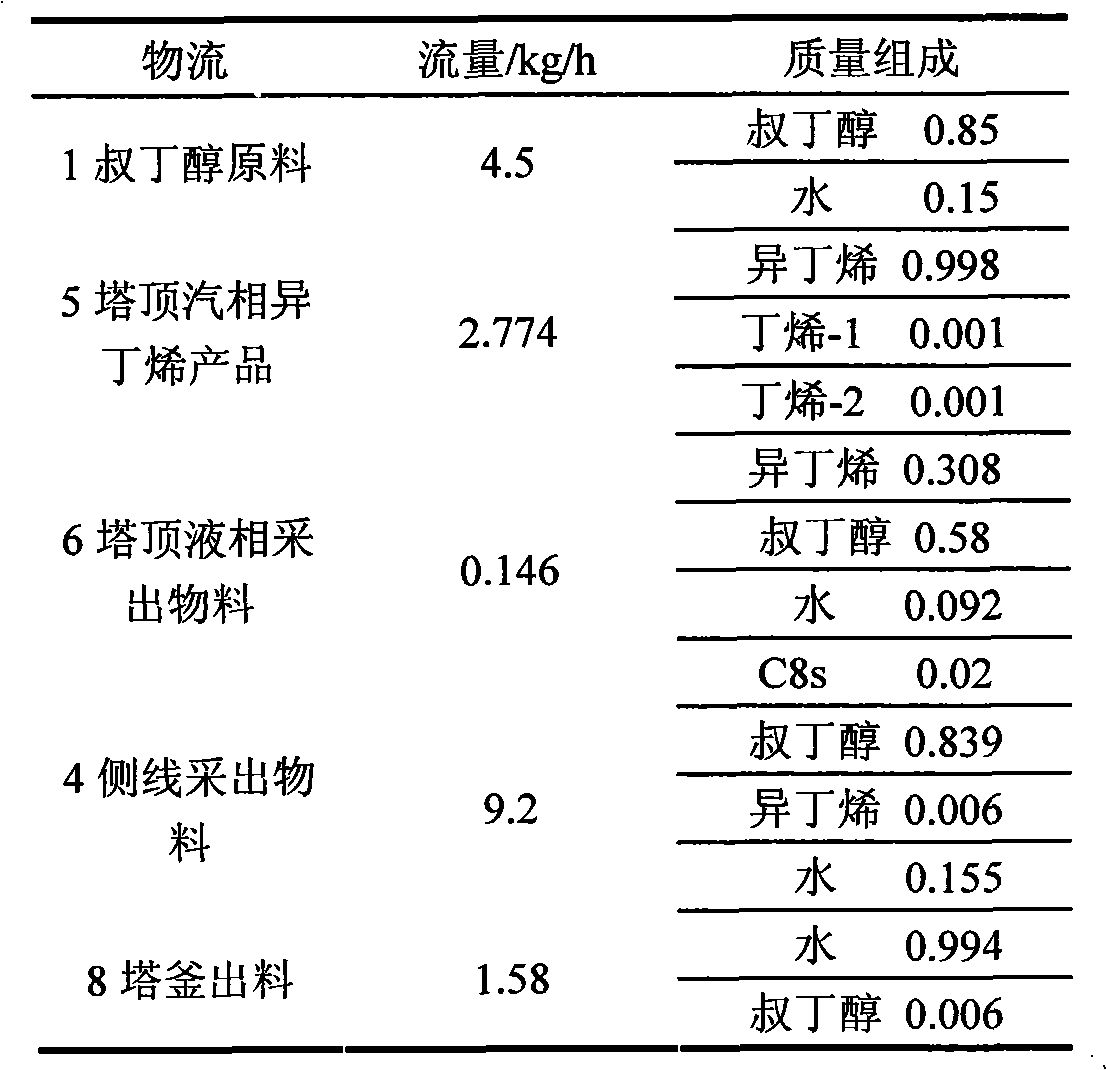

[0015] The tert-butanol raw material 1 with a near-azeotropic composition enters the fixed-bed reactor a, the reaction temperature is 85°C, and the reaction pressure is 1 MPa. The reaction product 3 enters the rectification tower b. The rectification tower b has 16 theoretical plates in total. 12 theoretical plates, the operating pressure is 0.12MPa, the temperature of the top subcondenser c is 5°C, and the isobutene product 5 is extracted from the vapor phase, which is condensed into a liquid product 7 after being cooled by the condenser d; the liquid condensed by the subcondenser The phase is mainly refluxed, a small amount of liquid phase material 6 is extracted, the side stream material 4 is collected from the third theoretical plate, mixed with the raw material 1, and then enters the reactor a, and the stream 8 is extracted from the tower kettle. The specific logistics flow and composition are shown in Table 1.

[0016] Table 1

[0017]

Embodiment 2

[0019] The tert-butanol raw material 1 with a near-azeotropic composition enters the fixed-bed reactor a, the reaction temperature is 60°C, and the reaction pressure is 1.5 MPa. The reaction product 3 enters the rectification column b, and the feeding position is the 30th theoretical plate. A theoretical plate, the operating pressure is 0.3MPa, the temperature of the top separator c is 29°C, and the isobutene product 5 is extracted from the vapor phase, which is condensed into a liquid product 7 after deep cooling by the condenser d; the liquid phase condensed by the separator Mainly reflux, a small amount of liquid phase material 6 is extracted, side stream material 4 is collected from the sixth theoretical plate, mixed with raw material 1, enters reactor a, and stream 8 is extracted from the tower kettle. The specific logistics flow and composition are shown in Table 2.

[0020] Table 2

[0021]

Embodiment 3

[0023] The tert-butanol raw material 1 with a near-azeotropic composition enters the fixed-bed reactor a, the reaction temperature is 95°C, and the reaction pressure is 0.5 MPa. The reaction product 3 enters the rectification tower b, and the feeding position is the 15th theoretical plate. There are 30 rectification towers in total. a theoretical plate, the operating pressure is 0.08MPa, the temperature of the top separator c is -5°C, and the isobutene product 5 is extracted from the vapor phase, which is condensed into a liquid product 7 after deep cooling by the condenser d; the liquid condensed by the separator The phase is mainly refluxed, a small amount of liquid phase material 6 is extracted, the side stream material 4 is collected from the third theoretical plate, mixed with the raw material 1, and then enters the reactor a, and the stream 8 is extracted from the tower kettle. The specific logistics flow and composition are shown in Table 3.

[0024] table 3

[0025] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com