Method for separating C6 mixed hydrocarbon by two-stage PSA

A technology of mixed hydrocarbons and separation process, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., which can solve the problems of high, complex and expensive equipment investment, and achieve the effects of low energy consumption, low investment and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Aromatics raffinate C6 mixed hydrocarbons, its composition is 77.9% methylcyclopentane and 22.1% n-hexane, high-purity methylcyclopentane and n-hexane were extracted respectively by two-stage pressure swing adsorption (PSA).

[0074] It can be seen from the data in Table 1 that the molecular weight of methylcyclopentane is 84.16, which is lower than that of n-hexane, which is 86.18. The boiling points of n-hexane and methylcyclopentane are 69°C and 71.8°C respectively, with a difference of 1.8°C, and it is difficult to separate them by distillation.

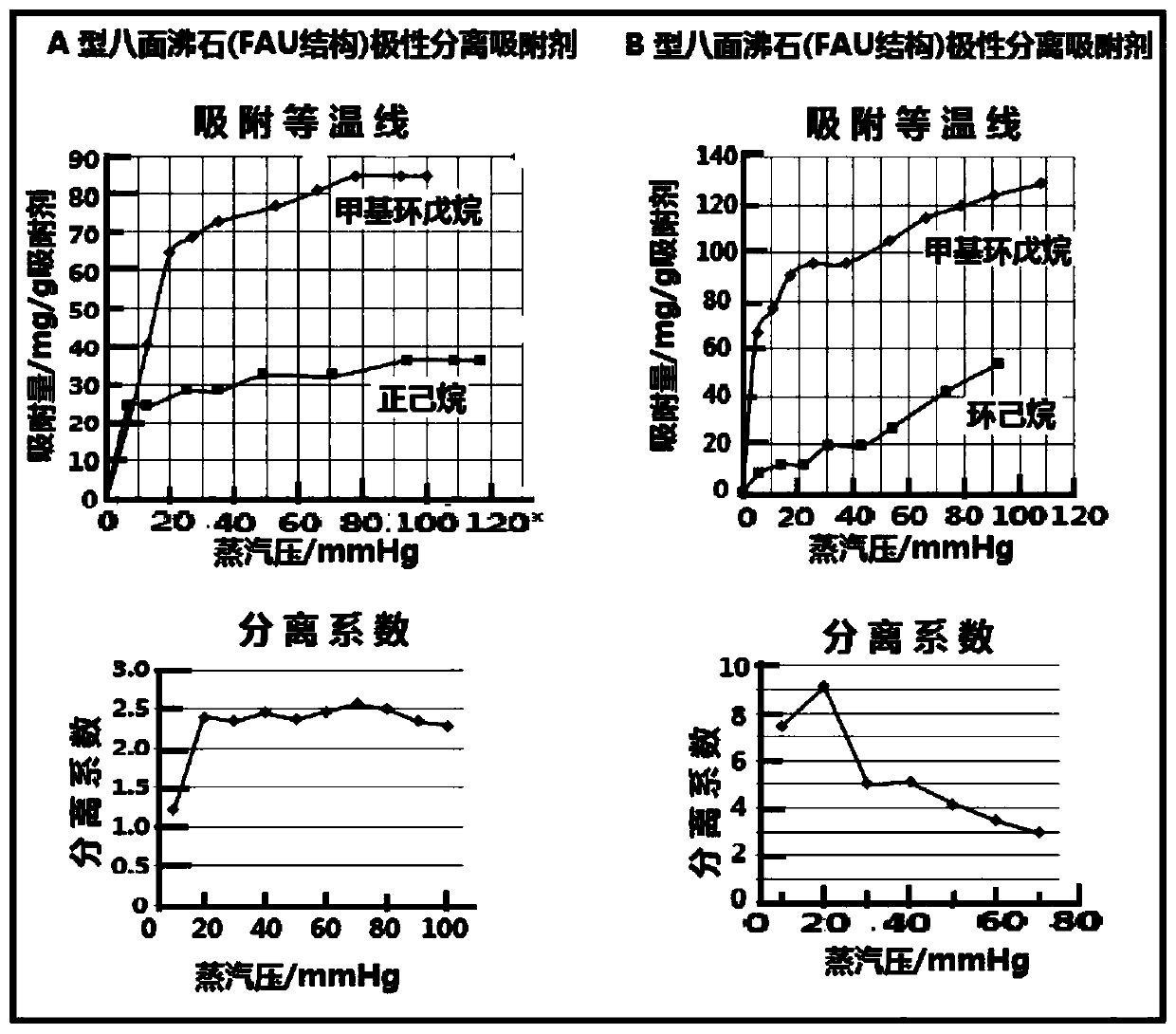

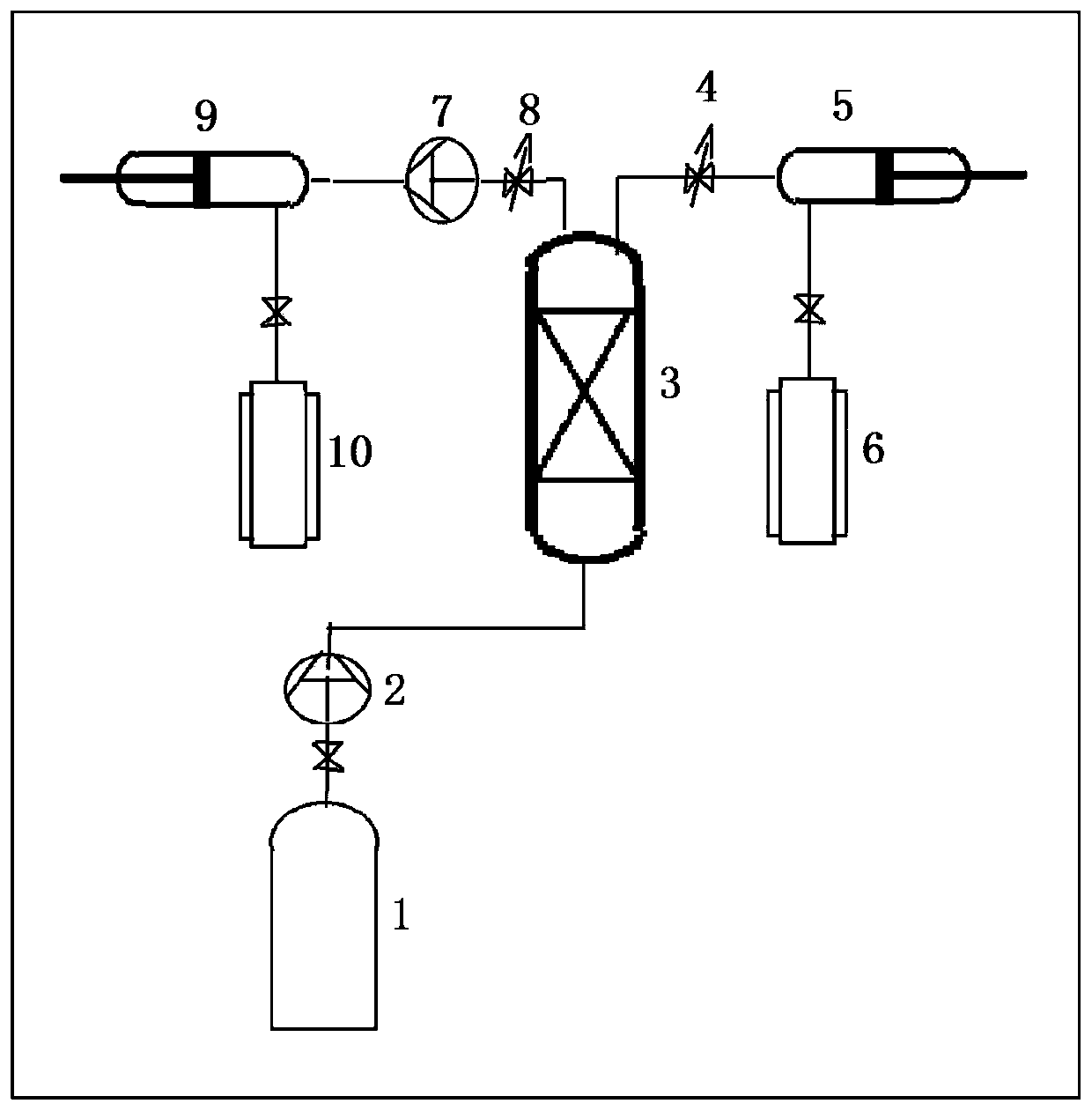

[0075] Wherein, the A-type modified large-pore faujasite polar separation adsorbent is used in the first stage of PSA separation, and the 5A (CaA) molecular sieve type selective separation adsorbent is used in the second stage of PSA adsorption separation, including the following steps:

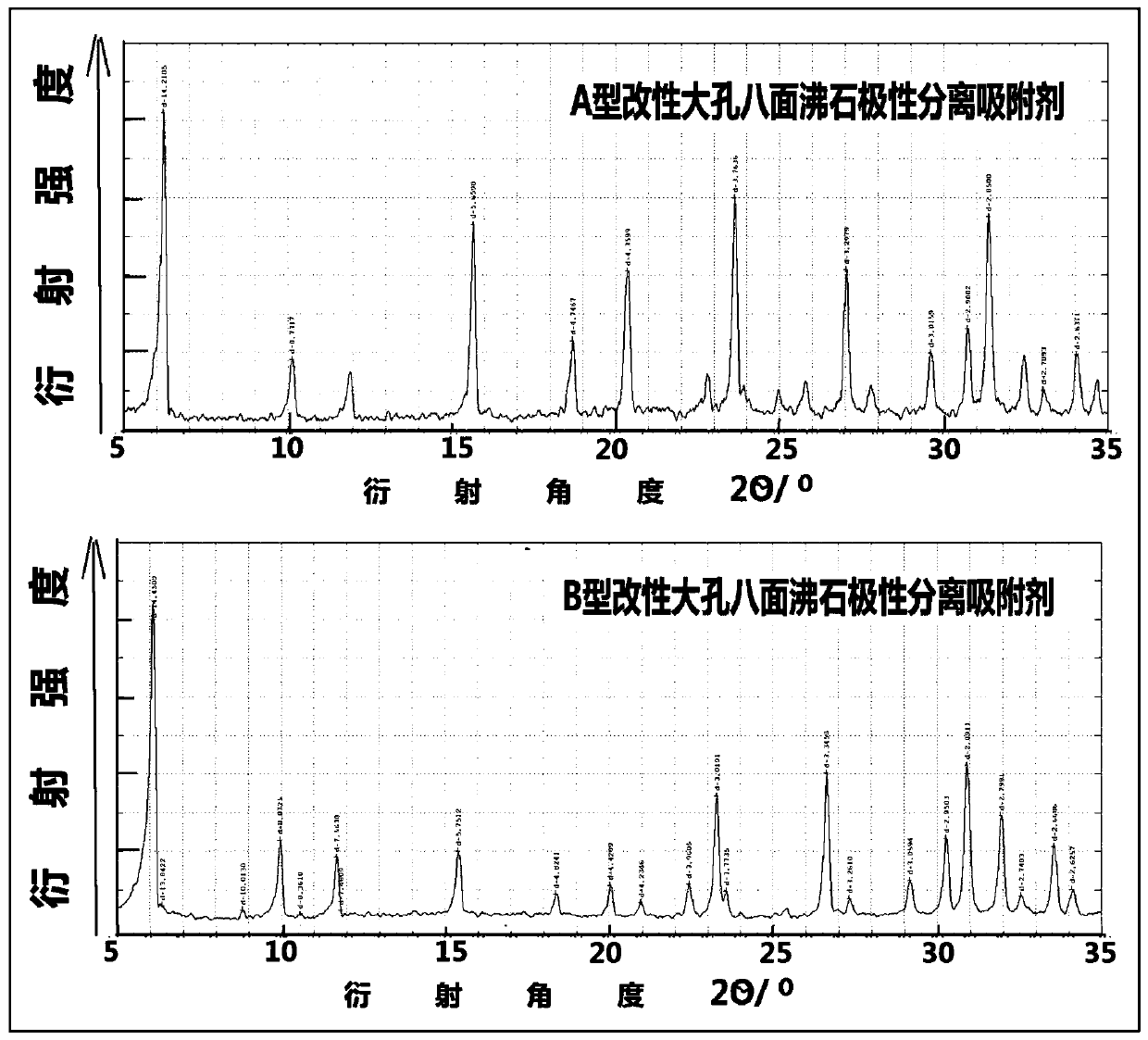

[0076] (1) Selection, preparation and phase identification of type A modified large-pore faujasite polar separation adsorbent

[0077] ...

Embodiment 2

[0092] The C6 mixed hydrocarbons of coal liquefied light oil are obtained by low-temperature distillation of coal liquefied light oil. The composition of C6 mixed hydrocarbons is 13.8% methylcyclopentane and 86.2% cyclohexane, and is obtained by two-stage pressure swing adsorption (PSA) Separately extract high-purity methylcyclopentane and cyclohexane. Among them, the first-stage PSA separation uses B-type modified large-pore faujasite polar separation adsorbent, and the second-stage PSA adsorption separation uses the MFI type (ZSM-5) hydrophobic silicalite type-selective separation adsorbent, including the following step:

[0093] (1) Selection, preparation and phase identification of B-type modified macroporous faujasite polar separation adsorbent

[0094]The faujasite-type hierarchical separation adsorbent adsorbs methylcyclopentane with a polarizability of 13.1 preferentially and separates it from cyclohexane molecules with a polarizability of 10.7. The basis for the typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com