A preparing method of cyclohexane

A technology of cyclohexane and methylcyclopentane, which is applied in the field of cyclohexane preparation, can solve the problems of harsh operating conditions and long process, and achieve the effects of mild reaction conditions, high product yield and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

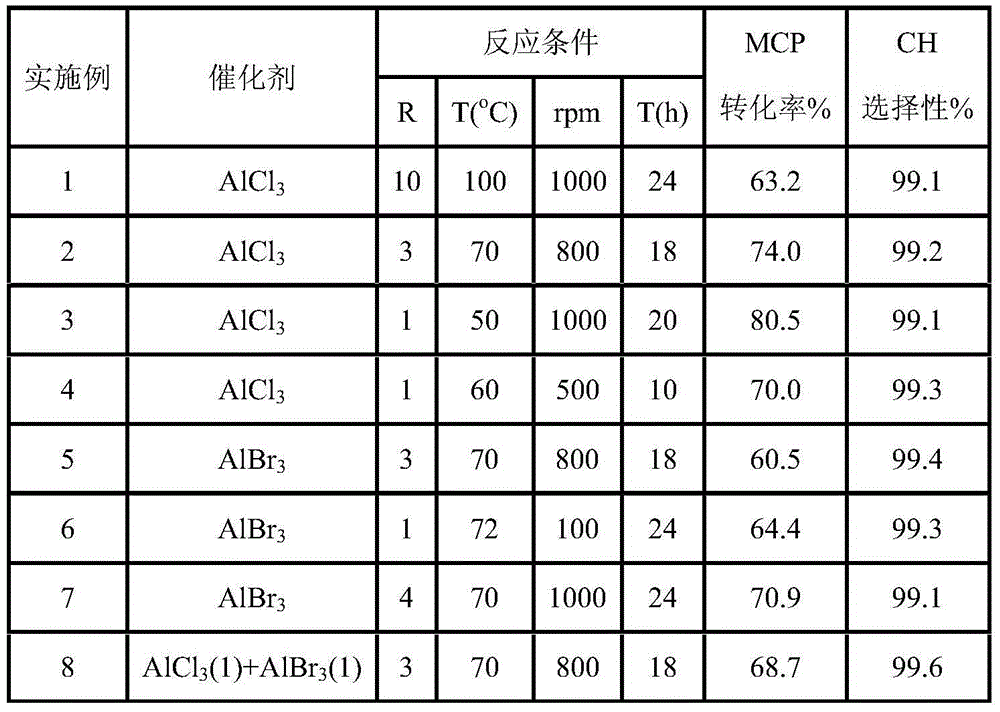

[0020] In a 50ml closed tank reactor, in anhydrous aluminum chloride (AlCl 3 ) catalyst, the reaction temperature is 100 ° C, with methylcyclopentane as the reaction raw material, the reaction raw material and AlCl 3 The weight ratio is 10, the stirring speed is 1000 rpm, the conversion rate of methylcyclopentane after 24 hours of reaction is 63.2%, and the product selectivity of cyclohexane is 99.1%.

[0021] For the convenience of comparison, the catalysts, reaction conditions and reaction results are listed in Table 1.

Embodiment 2

[0023] In a 50ml closed tank reactor, in anhydrous aluminum chloride (AlCl 3 ) catalyst, the reaction temperature is 70 ° C, with methylcyclopentane as the reaction raw material, the reaction raw material and AlCl 3 The weight ratio is 3, the stirring speed is 800 rpm, the conversion rate of methylcyclopentane after 18 hours of reaction is 74.2%, and the selectivity of cyclohexane product is 99.2%.

[0024] For the convenience of comparison, the catalysts, reaction conditions and reaction results are listed in Table 1.

Embodiment 3

[0026] In a 50ml closed tank reactor, in anhydrous aluminum chloride (AlCl 3 ) catalyst, the reaction temperature is 50 ° C, with methylcyclopentane as the reaction raw material, the reaction raw material and AlCl 3 The weight ratio is 1, the stirring speed is 1000 rpm, the conversion rate of methylcyclopentane after 20 hours of reaction is 80.5%, and the selectivity of cyclohexane product is 99.1%.

[0027] For the convenience of comparison, the catalysts, reaction conditions and reaction results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com