Technology for separating n-hexane-methylcyclopentane through extractive distillation

A technology of methylcyclopentane and extractive distillation, which is applied in the field of separation of n-hexane-methylcyclopentane, can solve the problem that high-purity n-hexane and methylcyclopentane cannot be obtained, and industrial-scale production costs are high. , the problem of not getting high-purity n-hexane products, etc., to achieve the effects of high purity and yield, low price, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

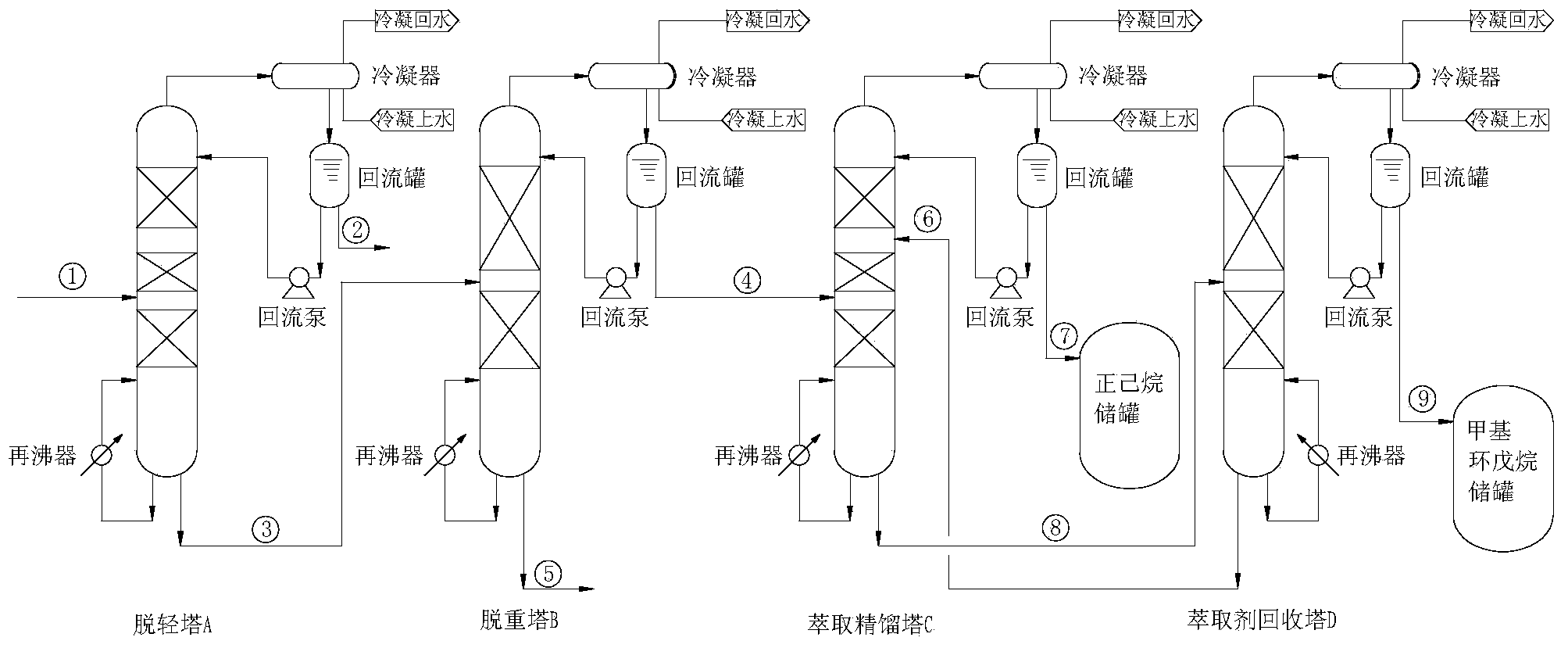

[0025] According to the technological process of the flow chart, the industrial raw materials are firstly delightened and deheavy concentrated, the experiment is carried out under normal pressure conditions, the tower kettle is heated by a reboiler, and the return flow at the top of the tower is condensed through the condenser and adjusted by a pneumatic control valve .

[0026] (1) Send the industrial raw materials containing n-hexane and methylcyclopentane ① into light removal tower A, control the top temperature of light removal tower A to 60°C, and the temperature of the bottom of light removal tower A to 69°C to remove light Component ② and light component ② flow out from the top of light removal tower A, condense through the condenser and return to the reflux tank, part of light component ② is used for reflux, and the reflux ratio of light component ② is 10:1. The material ③ after removal of light components ② flows out from the bottom of tower A;

[0027] (2) The mater...

Embodiment 2

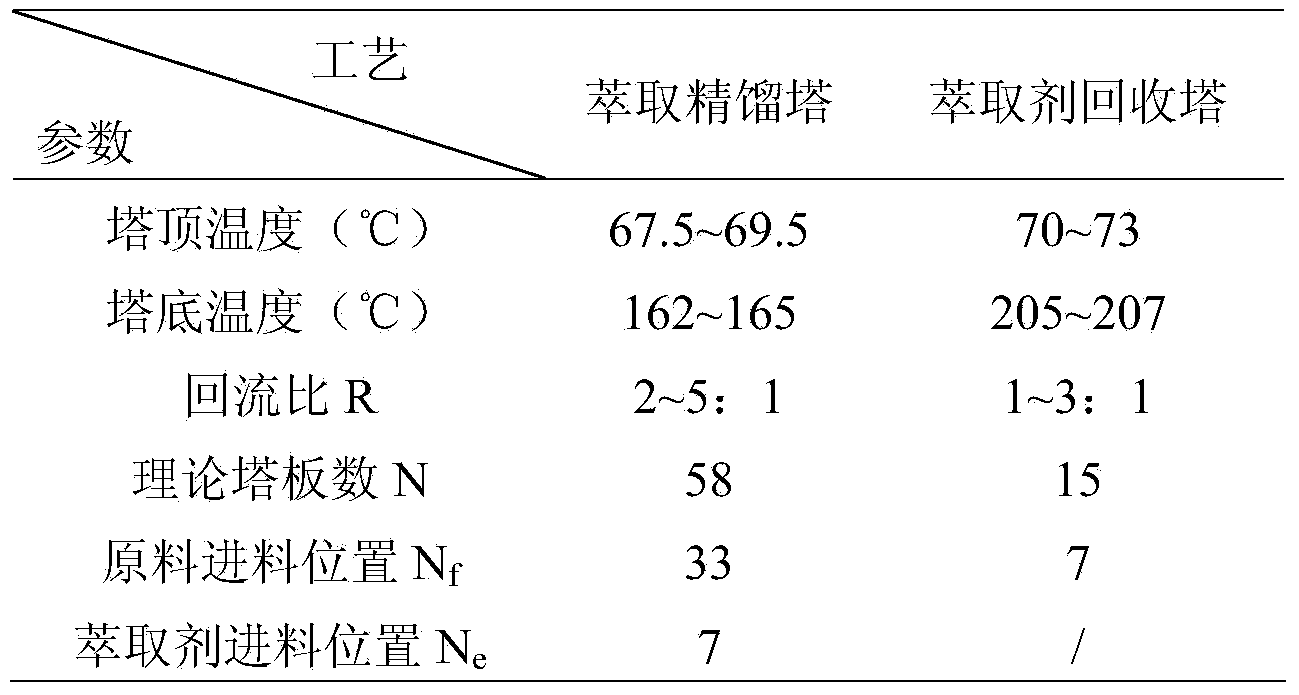

[0031] Control the temperature at the top of light removal tower A to 62°C, the temperature of the bottom of light removal tower A to 70.6°C, control the temperature at the top of light removal tower B to 68.9°C, and the temperature of the bottom of heavy removal tower B to 79.5°C, light components② The reflux ratio of the material ④ is 15:1, and the reflux ratio of the material ④ is 5:1. The temperature at the top of the extractive distillation column C is 68.2°C, and the temperature at the bottom of the extractive distillation column C is 163.5°C. The product n-hexane with a purity of 98.7% is obtained. The yield of n-hexane is 91.5%. It is 3:1. Control the temperature at the top of the extractant recovery tower C to 71.8°C, and the temperature at the bottom of the tower to 206.3°C. The operating conditions of the extractant recovery tower are shown in Table 1, and the product ⑨ of methylcyclopentane with a purity of 91.0% is obtained, methylcyclopentane The yield of alkane...

Embodiment 3

[0033] Control the temperature at the top of light removal tower A to 64°C, the temperature of the bottom of light removal tower A to 71.1°C, control the temperature at the top of light removal tower B to 69.1°C, and the temperature of the bottom of heavy removal tower B to 80.2°C, light components② The reflux ratio of the control material ④ is 6:1. The temperature at the top of the extractive distillation column C is 69.1°C, and the temperature at the bottom of the extractive distillation column C is 164°C. The product n-hexane with a purity of 99.0% is obtained. ⑦ The yield of n-hexane is 91.5%. It is 4:1. The temperature at the top of the extractant recovery tower C is controlled to be 72°C, and the temperature at the bottom of the tower is 206.5°C. The operating conditions of the extractant recovery tower are shown in Table 1, and the product ⑨ of methylcyclopentane with a purity of 91.3% is obtained, methylcyclopentane The yield of alkane is 90.3%; the reflux ratio of me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com