Method and apparatus for treating, sorting and recycling oil-containing discharged catalyst

An efflux catalyst and catalyst technology are applied in the field of oil-containing efflux catalyst treatment and sorting and recycling, and the reactor oil-containing efflux catalyst treatment and sorting and recycling fields, which can solve the problem of low oil phase recovery efficiency, high processing cost, etc. Resource waste and other problems, to achieve the effect of high catalyst degreasing efficiency, low operating cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

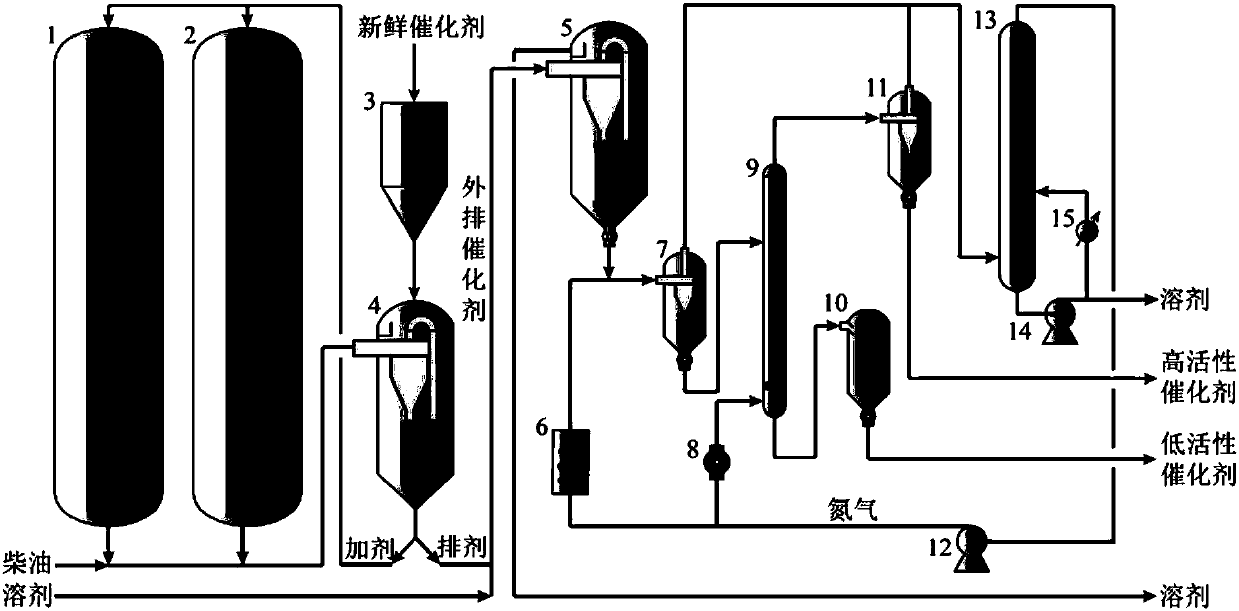

Method used

Image

Examples

Embodiment 1

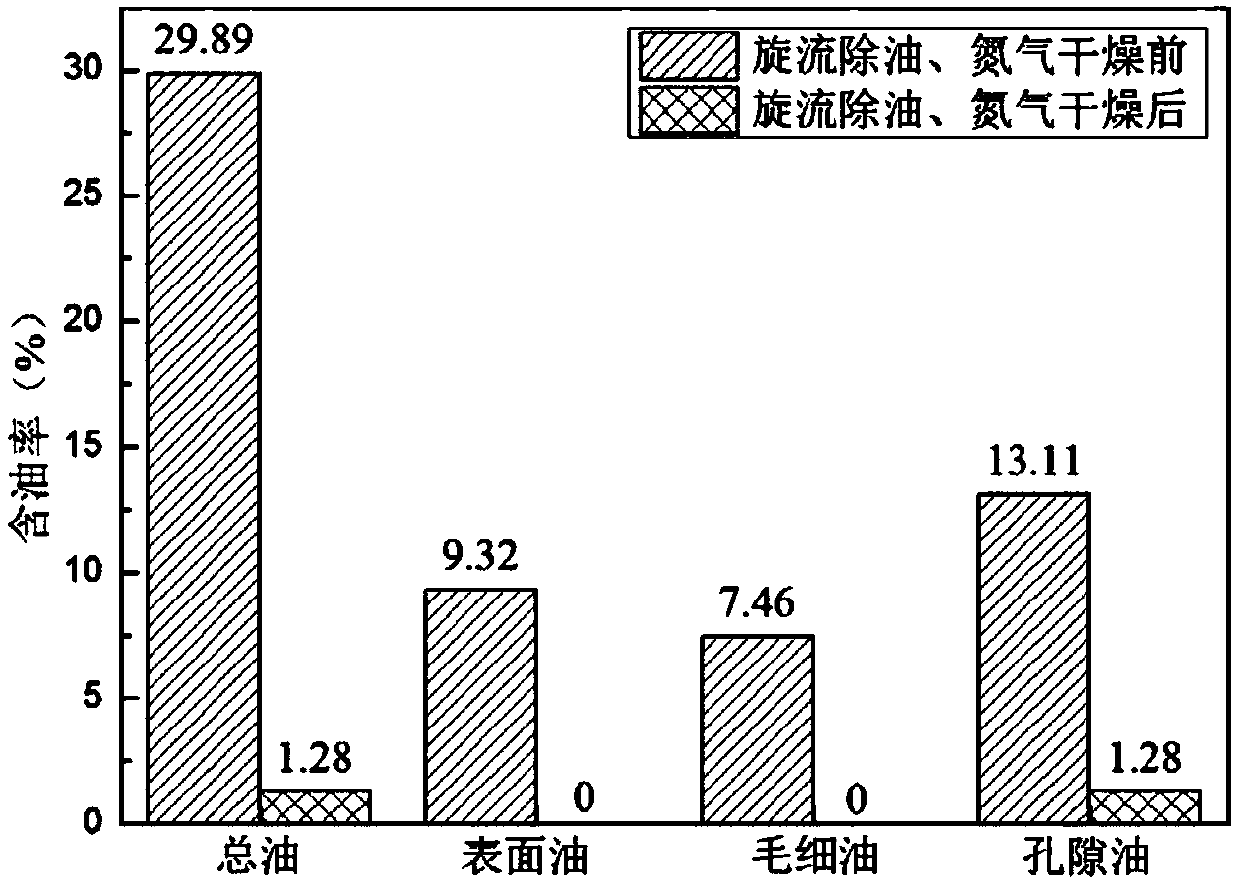

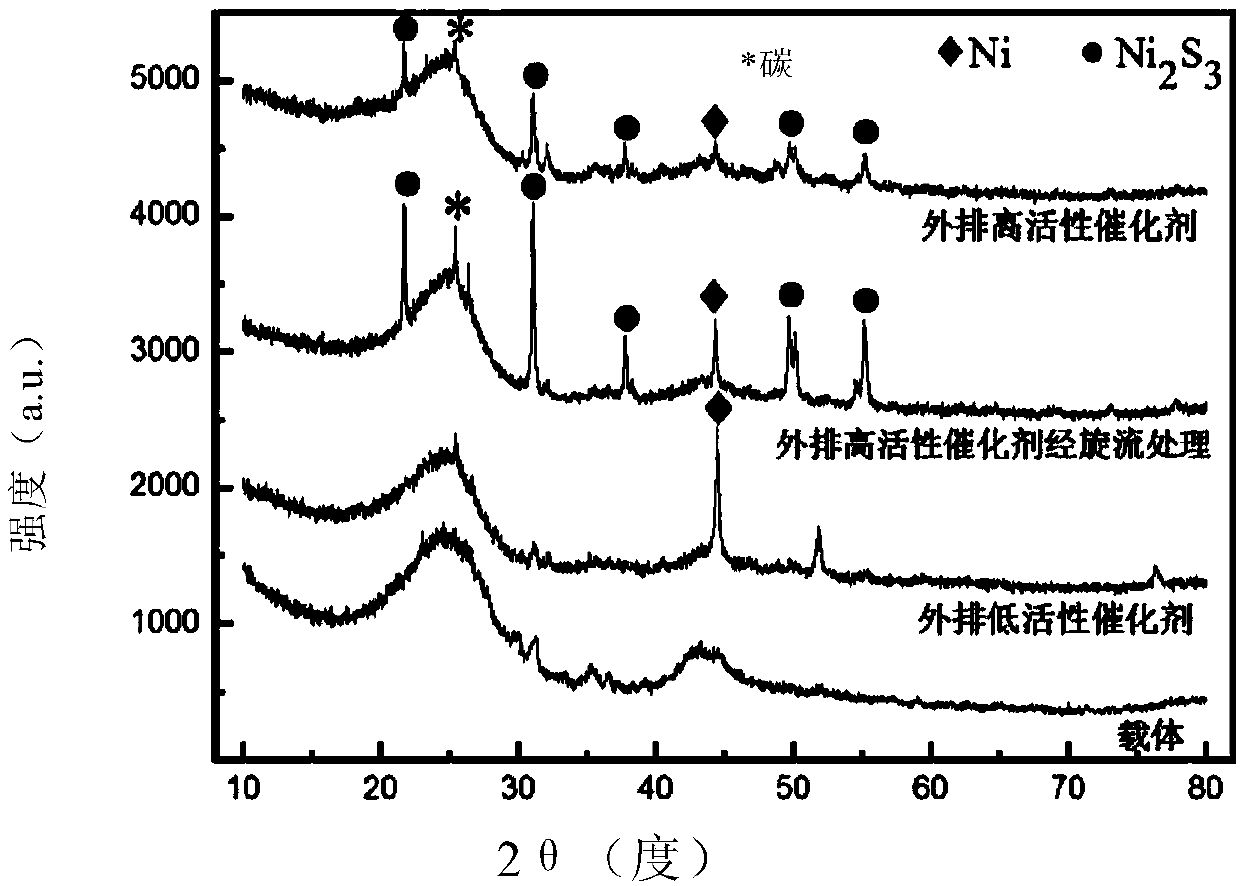

[0081] In a 2.6 million tons / year fluidized bed residual oil hydrogenation unit, according to the method and device of the present invention, the treatment and sorting and recycling of oil-containing efflux catalysts are carried out. The specific operation process and effects are described as follows:

[0082] 1. Properties of efflux catalyst

[0083] The catalyst discharged from the reactor contains residual oil, wax oil and diesel components. The daily fresh catalyst consumption is 7354 kg / day, and the equilibrium activity of the discharged catalyst is 54% of that of the new catalyst, among which the catalyst particles with high activity (>80% of the new catalyst activity) account for more than 1 / 2. The catalyst components are shown in Table 1 below.

[0084] Table 1 The composition of the efflux catalyst

[0085] components

Daily output (kg / day)

Sulphided nickel molybdenum catalyst

7354

carbon deposition

2208

Vanadium sulfide

60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com